Acorns, user experience and optimization

Acorns, user experience and optimization

With the advent of technologies like the iPad, the field of predictive maintenance has become an accessible and achievable goal for many businesses. The iPad allows anyone from small companies to large multi-facility corporations to implement and commit to a predictive maintenance program utilizing technology that is constantly improving.

The creation of a thousand forests is in one acorn. — Ralph Waldo Emerson

Acorn, meet iPad.

I saw the above quote along the Tampa Riverwalk while attending the Electrical Apparatus Service Association (EASA) convention. It made me ponder the infinite possibilities of that single acorn, and in turn, the boundless ways technology influences our every day.

With the advent of technologies like the iPad, the field of predictive maintenance has become an accessible and achievable goal for many businesses. Since the beginning of the tablet revolution companies have been searching for ways to exploit this new mobile capability across various industries. The iPad allows anyone from small companies to large multi-facility corporations to implement and commit to a predictive maintenance program utilizing technology that is constantly improving.

The field of predictive maintenance has come a long way since its inception. Machines can be monitored for various conditions and we can now predict and plan for downtime. Out of this cloud based industrial revolution have come numerous systems with multiple tools and programs that are cost prohibitive for many companies, take days or weeks of training, and have costly maintenance service agreements. At GTI Predictive Technology we are about cost efficient solutions that leverage the best and most prevalent technologies available. In this case, the iPad and Apple app store.

One thing that makes the iPad so successful is that it's focus was placed on the user experience, an often-ignored piece of the puzzle in our industry. In utilizing the iPad, you no longer need to carry around a multitude of clunky boxes for a single reading. The predictive maintenance arsenal is now run from a technology many of us already own.

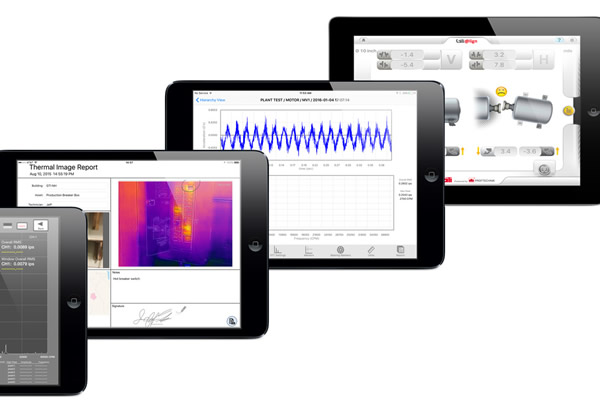

AT GTI Predictive, we leveraged this technology and software for its enhanced user experience. The iPad's familiarity and easy to use interface allows for quick adoption and minimized training. Need vibration analysis? We have an app for that. Field or shop precision machine balancing? We have an app for that too. Laser shaft alignment? You get the point. Our entire predictive maintenance platform is based on the iPad from vibration analysis to balancing and much more.

"Why iPad?" and "Is this available for other tablets?" are questions we hear all of the time. The answer is no. Let me tell you why.

- Apple values its developers. They are also concerned with the integrity of final products sold through their app store. We receive beta versions on new IOS software upgrades months before they are released to the public. This allows us to rigorously test and update our apps, if need be, in order to be compatible with the newest operating system. Not only do we test our apps, but Apple does as well. All apps sold through the app store must be vetted for accuracy and quality.

- Environment. Let's think about how and where PdM products are used. Shop floors can be dangerous, and employee safety is top of mind when monitoring machines. Machines utilizing various types of lubrication also need to be monitored. We place the iPad in an IT 67 rated rugged case approved for Class 1 Div 2.

- Amenities. At the end of the day it's still an iPad and has many functions outside of our apps. The wealth of commercially available accessories makes this a cost effective multipurpose tool on which you can download apps of your choosing to argument your PdM strategy or download books, games and entertainment apps.

- Apple App store. Most of us are familiar with the way an app store works. Using your tablet, you log on to the app store, purchase your app and it immediately starts downloading. Congratulations, you now own VibePro, our vibration analysis software, and will receive free upgrades every single time we update that app. Even if you purchased VibePro back in 2011 you are still receiving free updates.

Our PdM platform, unlike other companies that have costly annual maintenance fees, is cost effective. Through the app store we can only charge you once for the app. Again, considering the user experience, why pay for something you already own? We believe you should receive these upgrades for free and that an IOS update shouldn't make your equipment obsolete.

Think about this for the long term. You as a plant manager have purchased our vibration software and originally had one person monitoring your floor. Through acquisition of additional assets, you realize you need to hire someone new to help with your PdM strategy. No need to purchase the software again, you already own the app. Using the same user name and password attached to your iCloud account you can download the app onto any iPad, and as many as you want.

- Adaptability. Apps are frequently updated using customer feedback. We are able to quickly modify our apps based on suggestions from our customers as to ease of use and additional tools they would like included.

When we develop apps we follow a simple storyboard approach. This keeps things simple, minimizes training and negates the need for additional equipment such as a stylus (a must have for PdM apps on other tablets). Many of our apps are follow along, meaning that the app guides the user through the necessary input data needed for calculations and analysis.

Data collected on your route gets sent to VibePro Online in the GTI Cloud. The IoT has come to encompass the manufacturing industry as the IIoT. All data collected can be saved in our cloud for post process analysis and trending. Reports can be collated to include data from various apps including vibration, thermography and balancing, to name a few. Reports can even be sent directly from the floor to decision makers keeping the process streamlined and easy.

Technology has come a long way over the years and GTI Predictive Technology's ability to adapt to rising industry trends has allowed us to put together a successful platform optimized for today's consumers. Like the acorn, the iPad presents endless possibilities for continued innovation.

If you would like to learn more about the GTI Predictive Technology iPad maintenance platform, visit the company's website here. Tutorials and demos of the company's apps are available through the GTI Spindle YouTube channel.