Aerospace bushings manufacturer upgrades to 100% part inspection

Aerospace bushings manufacturer upgrades to 100% part inspection

A California-based manufacturer of precision aerospace bushings has installed a new inspection system to achieve 100 percent inspection of its parts.

A California-based manufacturer of precision aerospace bushings has installed a new inspection system to achieve 100 percent inspection of its parts.

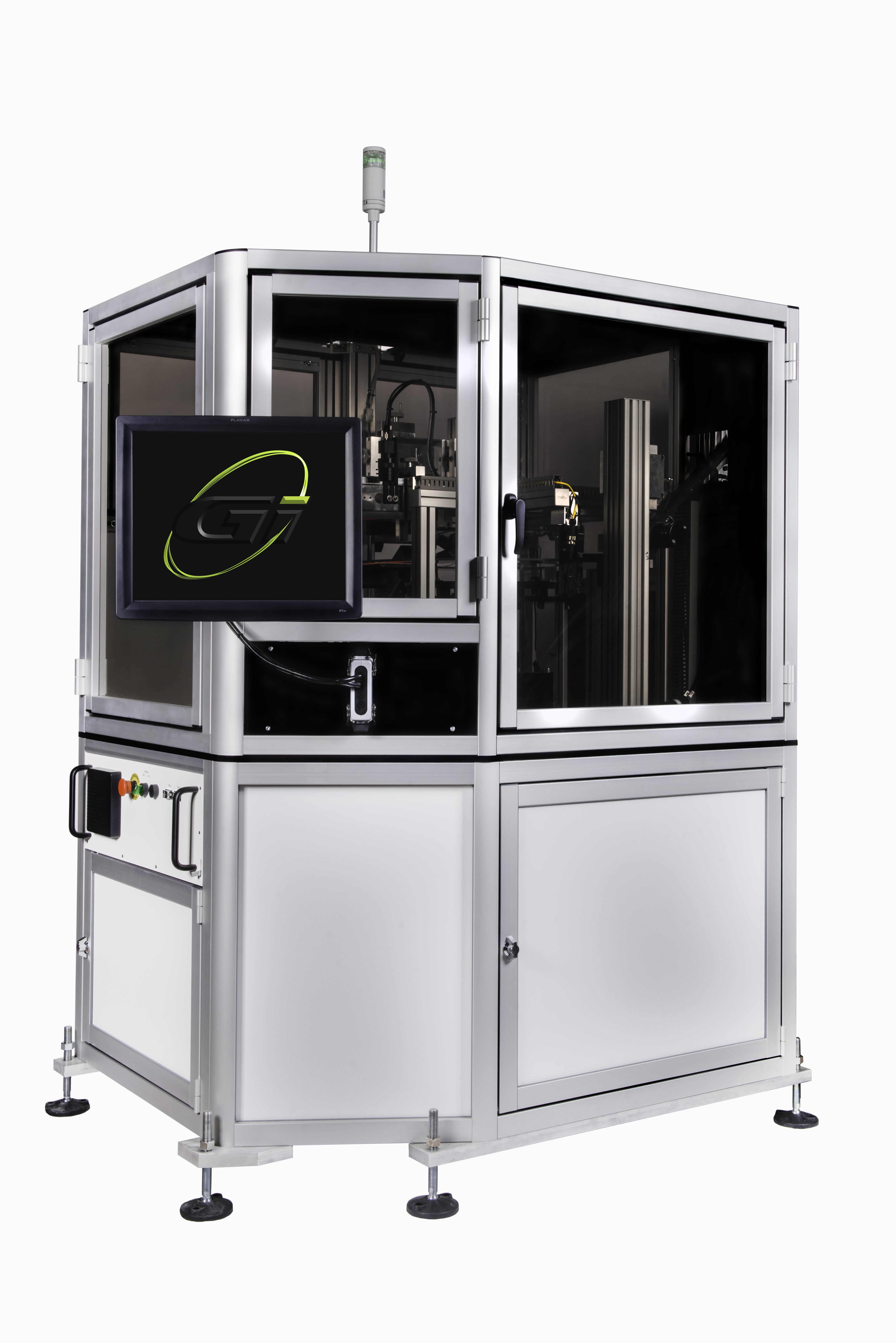

General Inspection LLC of Davisburg, Michigan, installed a Gi-100DT inspection system at the facility. The system is equipped with a total of six cameras providing complete dimensional inspection, internal and t external visual defect detection, and top and bottom surface inspection for a full range of turned aerospace bushings.

Dimensional inspection

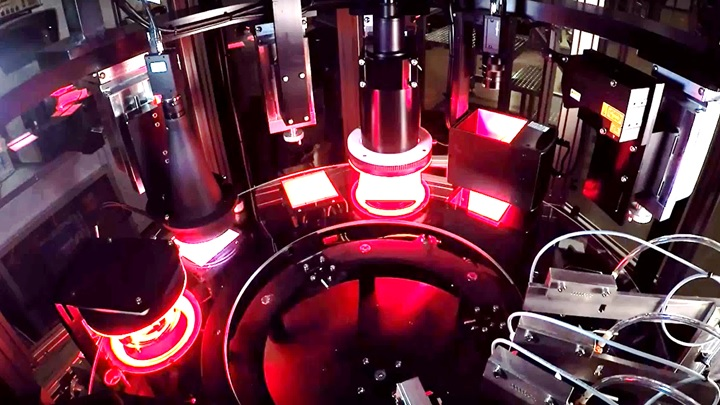

Aerospace bushings are 100 percent inspected by a camera-based inspection system as seen above.

The Gi-100DT comes standard with three cameras, one from the side, one from the bottom and one from the top. The side camera measures all profile features including threads, lengths, diameters, and angles. The top and bottom cameras measure OD, ID, roundness, and concentricity.

Parts are measured to print specifications through Gi's software, each dimension is saved and recalled by part number for fast part-to-part changeover.

Visual defect detection

In addition to the dimensional inspection, the Gi-100DT also detects surface defects on the top, bottom, and inner step diameters. The surface defects include dents, scratches, chatter, pitting, and chips.

The system is equipped with three additional cameras each with patented optics positioned above and below the parts to detect internal and external visual defects. Defects such as cracks, burrs, dents, and other damage are detected using Gi's sophisticated algorithms, advanced lighting techniques, and special, unobstructed part view handling technique.

After searching for an inspection system with complete dimensional and visual defect detection capabilities, the manufacturer selected Gi. Defect detection, fast changeover, and inspection rates of a minimum of 300 parts per minute were the deciding factors.

For more information, contact Gi at 248-625-0529.