ANCA, Tetralytix partner on virtual cutting tool design

ANCA, Tetralytix partner on virtual cutting tool design

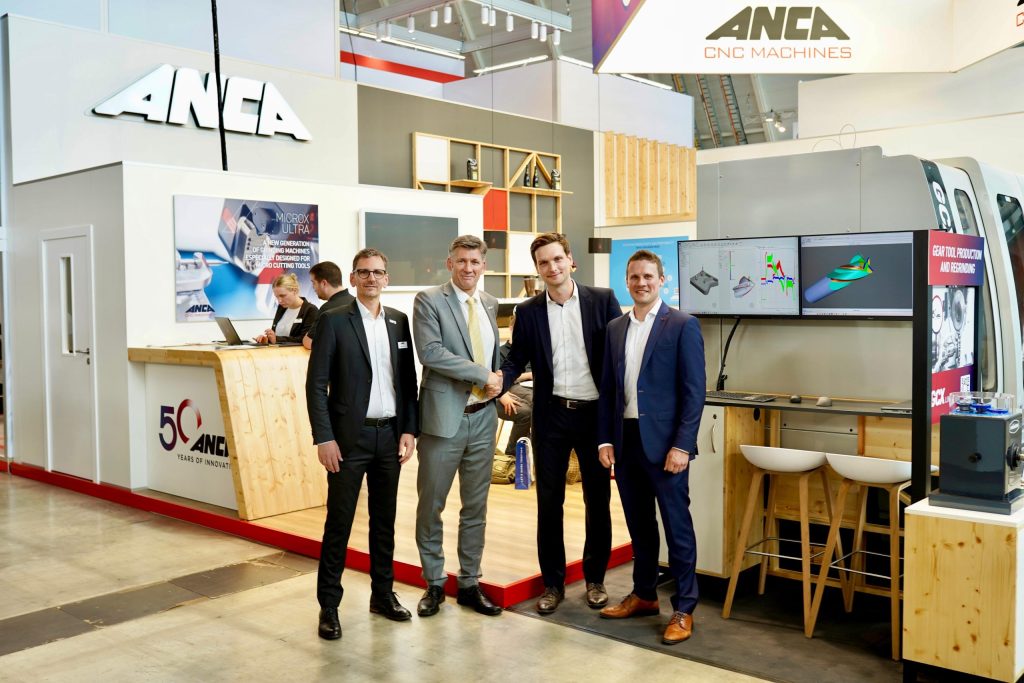

ANCA, a manufacturer of CNC grinding machines, and Tetralytix, a developer of simulation software for metal cutting technology, entered into a strategic collaboration in the field of virtual design for cutting tools.

ANCA, a manufacturer of CNC grinding machines, and Tetralytix, a developer of simulation software for metal cutting technology, entered into a strategic collaboration in the field of virtual design for cutting tools.

This partnership leverages the combined expertise of both companies to offer unique capabilities for the development of superior precision cutting tools and enhancing metal cutting technology.

The collaboration integrates ANCA's expertise in virtual modeling of tool geometries and industry-revolutionizing CIM3D tool verification software with Tetralytix's expertise in technological analysis through Toolyzer, a simulation tool for designing and optimizing cutting tools. An interface between CIM3D and Toolyzer will enable cutting tools to be developed faster and more cost-effectively, providing significant benefits to tool manufacturers.

"ANCA welcomes this partnership as it signals our commitment to empowering our customers with the most advanced and powerful software tools available. By working together, we're ensuring that cutting tool manufacturers have everything they need to innovate, optimize, and stay ahead in a rapidly evolving industry," said Martin U. Ripple, CEO at ANCA.

Dr.-Ing. Arne Mücke, Managing Director, Tetralytix, added, "The partnership with ANCA is a significant step towards creating added value and competitive advantages for our customers. The cooperation will make the benefits of digital cutting tool development visible in an unprecedented way."