Automated centerless grinding doubles production output for steel tap blanks

Automated grinding wheel. This method allo…" title="Grinding operation in which the workpiece rests on a knife-edge support, rotates through contact with a regulating or feed wheel and is ground by a grinding wheel. This method allo…" aria-label="Glossary: centerless grinding">centerless grinding doubles production output for steel tap blanks

Founded in 1952, New Jersey-based Glebar has designed and manufactured grinding machines for many different types of metal and other components, ranging from 60- to 80-HRC stainless parts to 0.002"-dia. titanium parts. For one application, an OEM of machine tooling equipment wished to increase output for steel tap blanks used to drill threaded holes as used in the machining and tooling industry.

Article provided by Glebar Co.

Founded in 1952, New Jersey-based Glebar has designed and manufactured grinding machines for many different types of metal and other components, ranging from 60- to 80-HRC stainless parts to 0.002"-dia. titanium parts. For one application, an OEM of machine tooling equipment wished to increase output for steel tap blanks used to drill threaded holes as used in the machining and tooling industry.

The customer was previously using an old Cincinnati machine and was only able to manually grind one component at a time, due to lack of automation and other features. In addition to speeding up the throughput time, achieving the exact tolerances is vital in order for the component to create the proper threads.

Solution

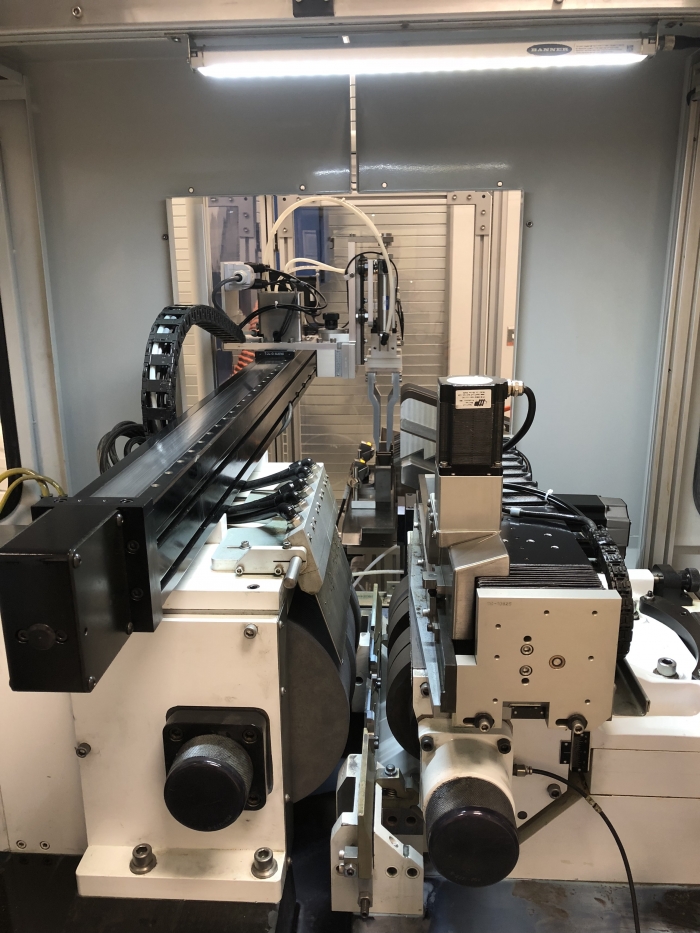

The fully automated GT-610 CNC infeed centerless grinder turnkey solution was chosen to address this challenge. The machine doubled the production output by grinding two parts-per-cycle. The GT-610 CNC's combination of automated features, such as CNC wheel dressing, independent upper and lower servo slides, quick-change gripper gantry and custom software, allowed this to happen.

The geometry requirements needed to control length to within +/-0.004" and two different diameters to +/-0.00015" with a 0.010" stock removal.

What made the GT-610 CNC the ideal choice to achieve these requirements was in large part its easy-to-operate design and ability to quickly change over the tooling, in under one hour versus multiple hours. The quick changeover can be credited to the twin-grip spindle the work wheel in mounted on. With the Glebar machine, the tailstock is quickly removed, and the operator can simply pull the wheel off of the spindle. Where with the previous machine, the entire wheel housing must be removed and replaced using a crane.

Next, the custom software communicates the data to the CNC dresser and the wheel is shaped automatically, without the use of manual template tracing dresser. Glebar's in-house software engineers are able to tailor the software to the exact specifications of the customer's part geometry.

Part adjustment is achieved by the use of Glebar's automated upper and lower slides, which control the distance of the regulating wheel and the work rest blade in relation to the work wheel. The GT-610's multiple-axis controller can position both grinding wheel slides to a resolution of 0.1 micron (0.000004"). Unlimited part configurations are stored in the robust HMI library.

The following process steps were involved in the grind process for the steel tap blanks:

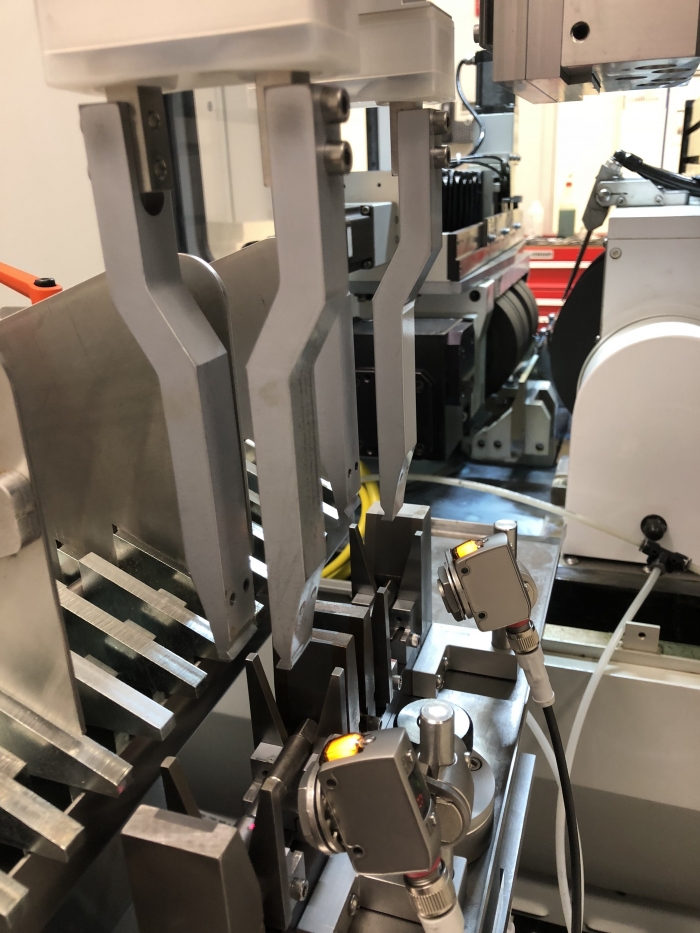

· An automated step feeder stages the parts two at a time.

· The overhead pick-and-place gantry handles two parts simultaneously.

· Laser sensors check the part's position.

· Parts are centerless infed ground two at a time.

· Vitrified wheel grinds parts to specification.

· CNC dresser with a diamond roller, ensures the wheel profile is accurate.

A video of this case study can be viewed here: www.glebar.com/case-studies/steel-taps