Boring tools will be a focus in CTE

Boring tools will be a focus in CTE

In connection with my canvassing efforts to best focus the boring tools topic scheduled for the January issue of Cutting Tool Engineering, I spoke with Harvey Patterson, product development engineer at Scientific Cutting Tools Inc., Simi Valley, Calif.

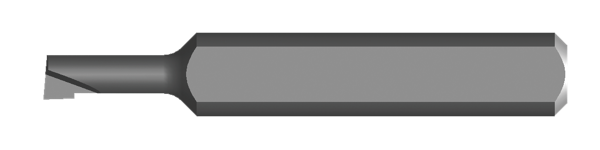

In connection with my canvassing efforts to best focus the boring tools topic scheduled for the January issue of Cutting Tool Engineering, I spoke with Harvey Patterson, product development engineer at Scientific Cutting Tools Inc., Simi Valley, Calif. When it comes to boring tools, he said SCT primarily makes ones for boring holes ½" in diameter and smaller and that he addressed most of the main issues about boring tools in the article CTE published last year titled "Troubleshooting solid-carbide boring bars requires the right diagnosis," such as chip packing and tapered holes.

According to Patterson, there hasn't been much innovation in the manufacturing and application of these tools during the past 10 to 20 years, but toolmakers such as SCT are producing smaller solid-carbide boring bars. The smallest from SCT is 0.015" in diameter. The tool can bore only a maximum depth of 0.050" because a lot of overhang for a single-point boring tool that size isn't possible.

External coolant would be applied for microboring applications, possibly via a toolholder with SCT's Coolant Ring technology, which enables coolant to be applied around the circumference of a boring bar. For tools 5/8" in diameter and smaller, there's not enough room in the tool to create a hollow section for adding a vibration-damping material, such as shot. Instead, an end user must reduce the cutting speed and increase the feed rate to eliminate chatter if it's present. "There are no hard and fast rules," he said.