CBN hones for improved surface finishing of machined superalloys

CBN hones for improved surface finishing of machined superalloys

By its very nature, high-nickel, iron or cobalt alloy steels, including Monel, Inconel, Incoloy, Invar, Rene and Hasteloy, are some of the most difficult materials to machine. Because these superalloys are designed to deliver high strength at extremely high temperatures in components often found in "hot" sections of engines and turbines, the stresses and heat generated during machining are considerable.

Article from Brush Research Manufacturing Co. Inc.

By its very nature, high-nickel, iron or cobalt alloy steels, including Monel, Inconel, Incoloy, Invar, Rene and Hasteloy, are some of the most difficult materials to machine. Because these superalloys are designed to deliver high strength at extremely high temperatures in components often found in "hot" sections of engines and turbines, the stresses and heat generated during machining are considerable.

In this process, the edge of the cutting tool is exposed to considerable mechanical stress, strain and heat. High compressive and shearing forces attack this edge, increasing temperatures such that the cutting tools can begin to lose hardness. This can produce a "gummy" machining behavior and also cause workhardening.

According to Janos Garaczi, president of Delta Machine Co. LLC., a company that specializes in machining complex, tight-tolerance parts out of titanium, nickel alloys, stainless steel, aluminum, plastics and other exotic alloys, this is caused when chips do not break away cleanly from the workpiece. Instead, the material is just "pushed" to one side.

"It can be really difficult to turn or mill this type of material because it doesn't produce a clear shearing action. Instead it just kind of pushes the material to the side," explains Garaczi.

"Gummy" machining is also the cause of heavy burrs in drilled holes or grooves.

"The burrs are one of the biggest problems," adds Garaczi. "Even during 'grooving,' if you cut the material from one side, it just pushes the burr to the edge; and if you approach it from the other side, it just pushes it back. It doesn't want to break off the material cleanly. As soon as the tool gets a bit dull it gets a lot worse so sharp tools with the right geometry are key."

The general poor machinability ultimately compromises surface integrity of the parts, says Garaczi, which is problematic given that is one of the primary causes of failure of these types of components.

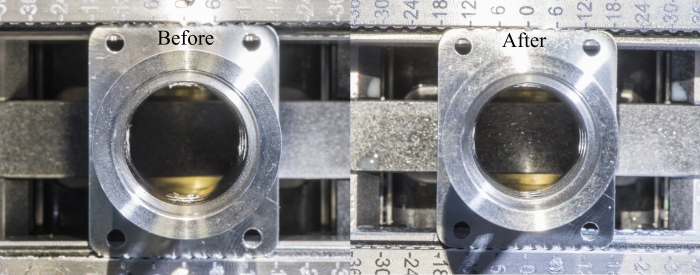

Given the critical nature of the applications in which these components are utilized, most machined superalloy parts must therefore undergo a surface finishing operation to remove workhardened layers and any heavy burrs. Doing so has additional benefits, including reducing the risk of oxidation and stress corrosion cracking (SCC).

Although this has traditionally been achieved through an expensive, messy and time-consuming grinding process, new flexible hones are simplifying the task by incorporating one of the toughest, hardest materials on the planet: CBN.

CBN combines the highest hardness with excellent toughness to provide the optimum surface finish. Flexible hones made of this type of material can be mounted on CNC equipment for automated operations or used in the field with handheld power tools to wear away work-hardened surfaces without inducing additional thermal distortion.

Superalloys

High-nickel alloy steels are prized within these markets because of the excellent resistance to corrosion and heat with strength, toughness, metallurgical stability, and weldability. These superalloys are a great choice for applications that require chemical resistance and strength at elevated characteristics. Their material properties include low expansion at severe temperatures and creep resistance under high stress conditions.

As such, superalloys are widely used as material for the hottest parts of complex equipment, including nuclear power components, high-performance automotive parts and jet engine turbines. Nickel, iron and cobalt alloys are also used broadly for aerospace components, medical devices, petrochemical and refining applications and thermal processing.

According to Garaczi, with the right cutting tools milling nickel alloys and stainless steels is still limited as to the surface finish that can be achieved to at best 32 Ra. With turning, 16 Ra is possible, but most of the time it requires a grinding or polishing step.

"Grinding is a very common process in these cases, but it is very time consuming and very expensive to have to grind a part," he says. "In some cases, it could take longer than the initial machining."

As a result, Garaczi says Delta Machine often sends parts out for grinding or polishing, opting to not perform this type of operation in house.

Flexible Hones

For many machine shops, a flexible hone is a much more efficient tool for overall surface finishing. The low-cost tool is often used for sophisticated surfacing, deburring, edge-blending and cleaning.

Until recently, however, flexible hones with CBN abrasive were only available by special order. Now, the company that invented the Flex-Hone tool, Brush Research Manufacturing, Los Angeles, offers CBN surface finishing solutions part of its standard product line.

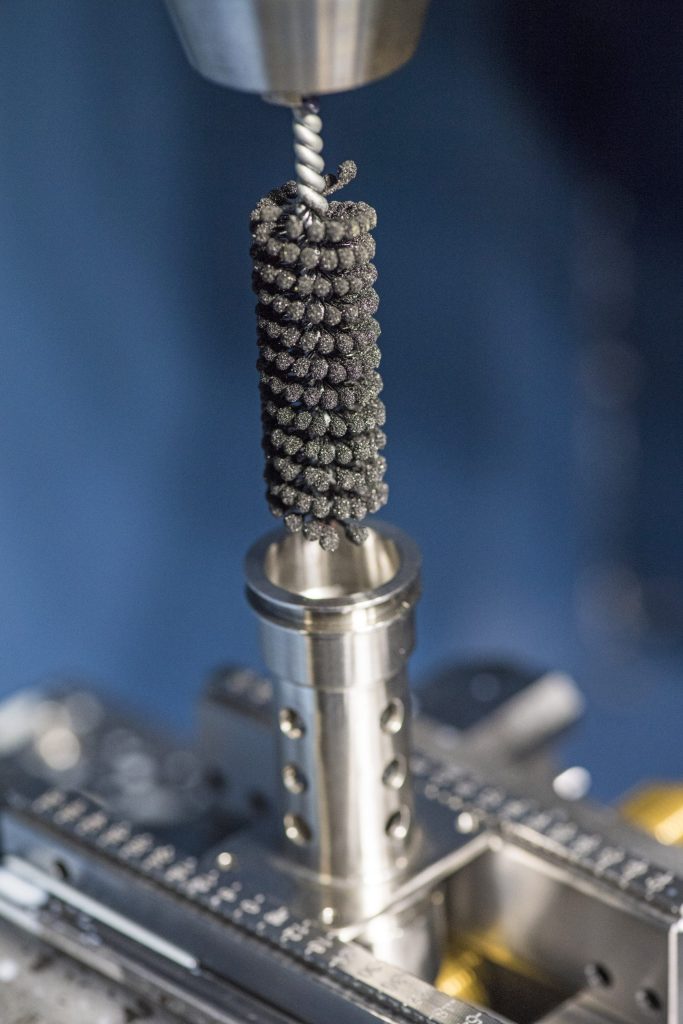

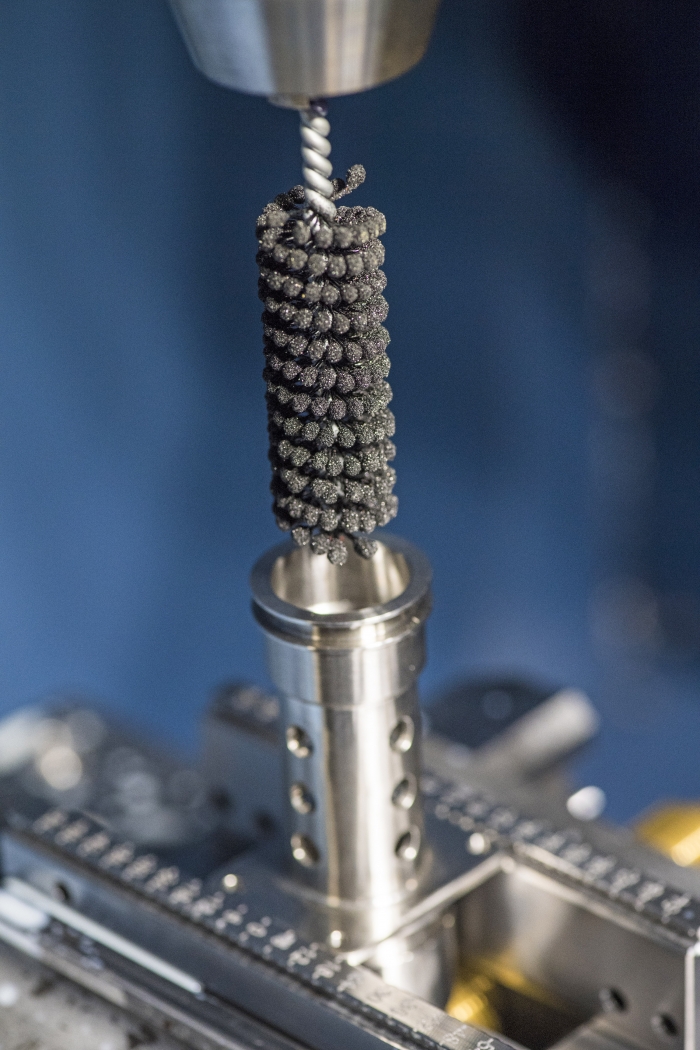

Somewhat resembling a spinning bottlebrush, the Flex-Hone tool is characterized by abrasive globules that are permanently mounted to flexible filaments that are attached to a center shaft. With its low-pressure, low-temperature abrading process, BRM's CBN Flex-Hone tools can remove workhardened layers and deburr parts without disturbing the underlying metallurgical structure.

Standard CBN Flex-Hone tools come in sizes ranging from 4mm to 20mm in three different mesh sizes: 170/200, 800, and 2500. Larger sized products from 22mm to 38mm and additional mesh sizes are available by special order.

Garaczi says he can see the advantage of being able to install a flexible hone into CNC equipment to automate the process and speed up the time when finishing superalloys and stainless steels.

Garaczi is in a unique position, having started with the company as a machinist and eventually working his way to president and owner. As such, he remains responsible for much of the programming, setups and purchasing.

He says when making decisions about what tools to purchase it is often on a project-by-project basis. However, if the tool can reduce cycle times versus its cost, it is an easy decision.

"There are definitely scenarios where it would be good to be able to perform surface finishing of this type of material on CNCs," says Garaczi. "It would really save a lot of time and extra processing cost."