Celebrating 50 years of Wohlhaupter’s MultiBore

Celebrating 50 years of Wohlhaupter’s MultiBore

Allied Machine and Engineering, a leading manufacturer of holemaking and finishing cutting tools for the metal cutting industry, celebrates 50 years of Wohlhaupter's MultiBore, the world's first modular boring system.

Allied Machine and Engineering, a leading manufacturer of holemaking and finishing cutting tools for the metal cutting industry, celebrates 50 years of Wohlhaupter's MultiBore, the world's first modular boring system.

In 1973, the company said that Wohlhaupter's MultiBore was the first that allowed boring tools to be changed directly at the spindle. While still a bestseller 50 years later, MultiBore now has a much wider range of machining operations that it is used for.

Until the early 1970s, universal facing and boring heads were used for rough and fine boring. These boring heads had an integrated shank specifically designed for the machine spindle of the corresponding machine manufacturer. However, every machine manufacturer had their own facing and boring heads, even if some of these came from the same manufacturer, in many cases Wohlhaupter. There were no standardized spindle connection points, so users had to have their tools for each machine type.

were used for rough and fine boring. These boring heads had an integrated shank specifically designed for the machine spindle of the corresponding machine manufacturer. However, every machine manufacturer had their own facing and boring heads, even if some of these came from the same manufacturer, in many cases Wohlhaupter. There were no standardized spindle connection points, so users had to have their tools for each machine type.

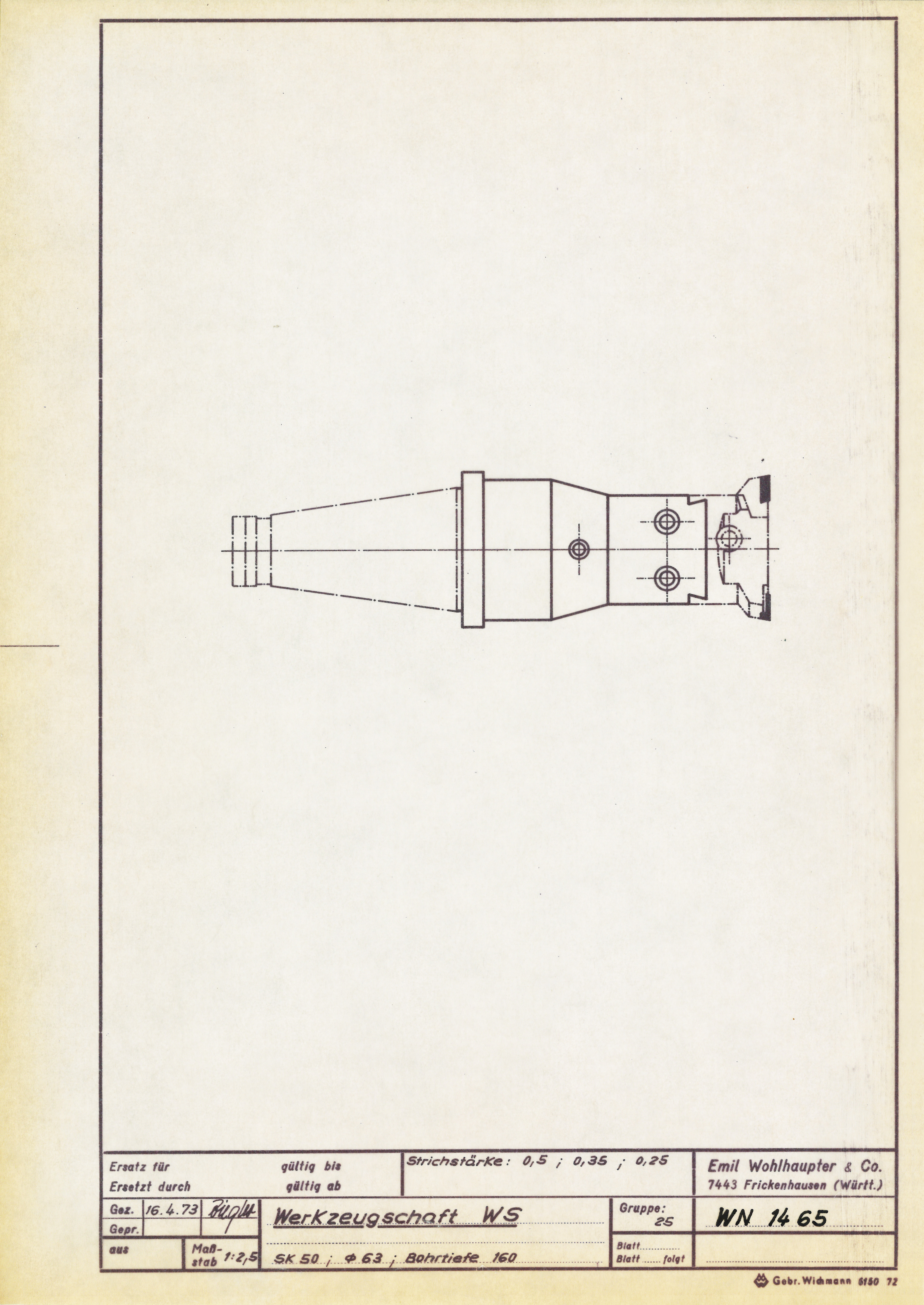

Ultimately, this created a demand for universally applicable modular tools. according to the company. Instead of a one-piece boring head, it made sense to design tools modularly to fit on all machine tools with different basic holders while also having the capability to be individually assembled into complete tools adapted to the workpiece. Wohlhaupter implemented this idea with MultiBore and presented the new product for the first time at the Hanover Trade Fair in 1973.

Machine manufacturers quickly decided to supply their machining centers with these new tools, marking the beginning of Wohlhaupter's success story. Today, MultiBore is still the central product area in Wohlhaupter's portfolio — now in many different versions to meet the increased demands of the market.

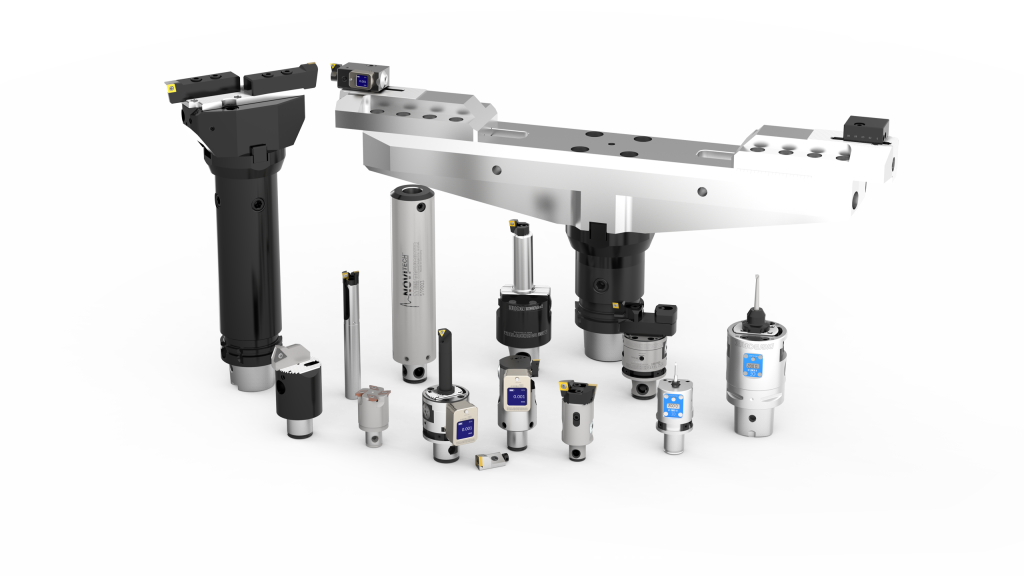

As a connection between the machine tool and the MultiBore modular components, the basic holders are supplied for all machine tools. With a complete diameter range of 0.016" – 128.150" (0.4 mm - 3255 mm), MultiBore boring tools fit directly into the master shanks or intermediate modules can be added to create full assemblies adaptable to the workpiece and fixturing.

Wohlhaupter currently offers the world's largest range of precision boring tools ideal for high-volume jobs that require repeated precision over the length of the entire operation.

"When MultiBore was launched in 1973, it was the world's first m odular boring tool and a real sensation for the industry. Since then, it has proven itself in millions of applications and is still a key product in our portfolio today, which we have continuously developed and adapted to the respective requirements. With MultiBore, we now offer the world's largest range of precision boring tools," explains Frank M.Wohlhaupter, managing partner of Wohlhaupter.

odular boring tool and a real sensation for the industry. Since then, it has proven itself in millions of applications and is still a key product in our portfolio today, which we have continuously developed and adapted to the respective requirements. With MultiBore, we now offer the world's largest range of precision boring tools," explains Frank M.Wohlhaupter, managing partner of Wohlhaupter.