CGTech Inc. to demo Force optimization and Vericut 9.0 at WMTS

CGTech Inc. to demo Force optimization and Vericut 9.0 at WMTS

Irvine, CA - At the Western Manufacturing Technology Show (WMTS), June 4-6, 2019, CGTech will demonstrate VERICUT's Force optimization module and new graphics and features coming soon in version 9.0 in booth #230.

Irvine, CA - At the Western Manufacturing Technology Show (WMTS), June 4-6, 2019, CGTech will demonstrate VERICUT's Force optimization module and new graphics and features coming soon in version 9.0 in booth #230.

"CGTech is committed to helping customers improve their competitive stance through NC toolpath and process optimization. CGTech consistently works to improve simulation performance, and to provide powerful and easy-to-use features that streamline each user's verification process," says VERICUT Product Manager, Gene Granata.

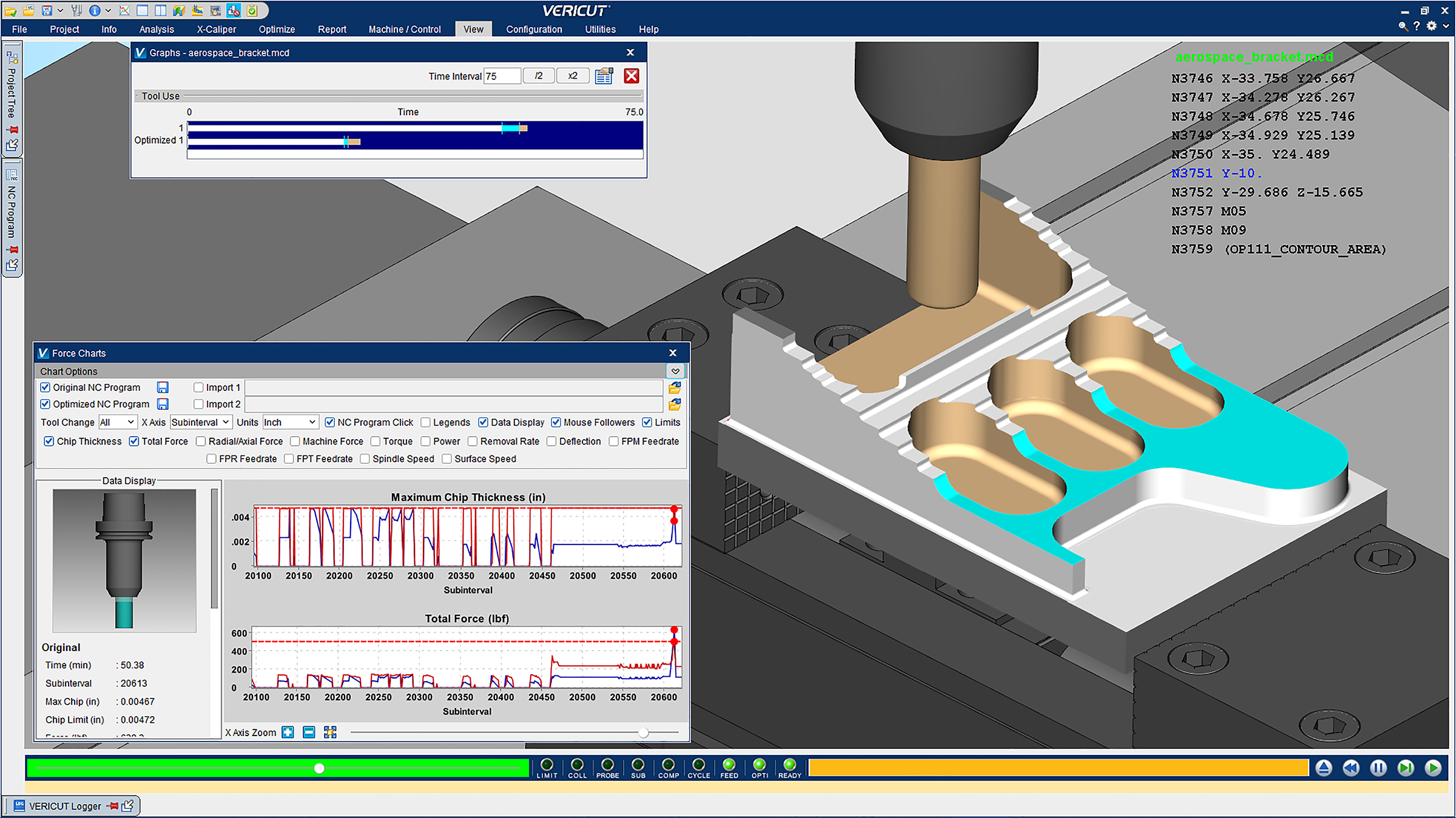

VERICUT's Force optimization reduces machining times by as much as 30-70%, even for superalloy metals, and makes cutters last longer.

• New enhanced graphics –Sharper views of the cutting process, enhanced performance, and flexibility to rotate or zoom while cutting. Improvements in the view environment including realism, improved translucency, metallic and other appearances.

• Improved efficiency – use major functions (like Section, X-Caliper and AUTO-DIFF) in any view and fluent switching between Workpiece and Machine views, layouts and docking arrangements.

• Added power and convenience – more and easier ways to section the part, streamlined setup for toolpath optimization, and significant enhancements for lathe and mill-turn tooling.