Complete machining of truck camshafts

Complete machining of truck camshafts

Effective complete machining of DAF camshafts for commercial vehicles is based on the sophisticated interplay between high performance high-performance linear motors, ultra-precise in-process measuring systems and easily accessible components. The Dutch truck manufacturer is extending its camshaft machining operations by adding the modular concept on the new platform 6.

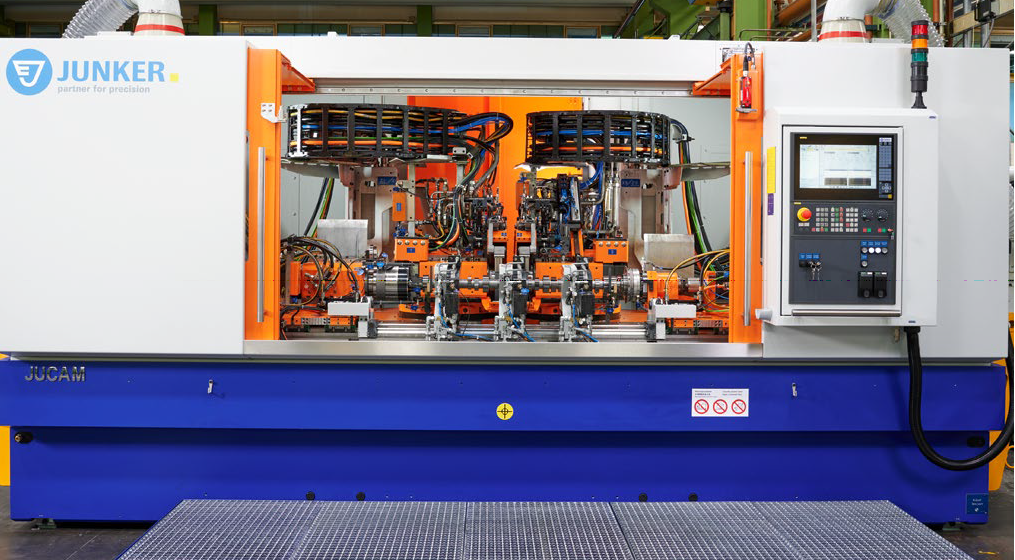

Effective complete machining of DAF camshafts for commercial vehicles is based on the sophisticated interplay between high performance linear motors, ultra-precise in-process measuring systems and easily accessible components. The Dutch truck manufacturer is extending its camshaft machining operations by adding the modular concept on the new platform 6.

Comfortable furnishings, long maintenance intervals and excellent driving dynamics are the reasons for purchasing reliable DAF trucks. DAF praises its customers with the highest level of efficiency, maximum driving comfort and a high residual value.

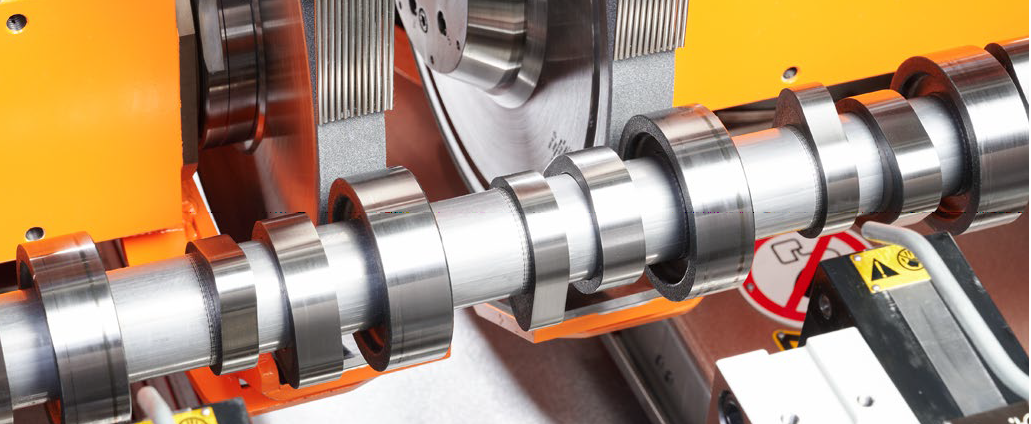

The precisely machined camshafts ensure that the engines of commercial vehicles function faultlessly and constantly for a high mileage. With the JUCAM 6L, these are machined efficiently and ultra precisely in a single clamping set-up. "The camshafts are used in the six-cylinder diesel engine series of XF and CF models," explained Wannes Bloemen, Senior Production Engineer, from DAF in Eindhoven, the Netherlands.

Short cycle times ensure efficiency

Two wheelheads with four grinding spindles were installed in the grinding machine. The camshaft is clamped between centers, an integrated driver and a retractable jaw chuck. The ultra-precise in-process measuring systems ensure perfect radial and longitudinal positioning. First the bearings are machined, followed by the pump cams and inlet and outlet cams. An additional step to deburr the elements is not required.

JUNKER's non-cylindrical grinding machine, JUCAM, provides process reliability by machining in a single clamping set-up. Bloemen said, "Halving the cycle times while complying with the tolerances is an optimum result."

Top speeds are achieved especially with the installed linear motors and the proven hydrostatic guides, as well as a reliable coolant system. The complete machining does away with the need for repeated loading and unloading. Within a defined spectrum of workpieces, the grinding-machine/" data-glossary-id="141847" data-glossary-teaser="Powers a grinding wheel or other abrasive tool for the purpose of removing metal and finishing workpieces to close tolerances. Provides smooth, square, parallel and accurate workpi…" title="Powers a grinding wheel or other abrasive tool for the purpose of removing metal and finishing workpieces to close tolerances. Provides smooth, square, parallel and accurate workpi…" aria-label="Glossary: grinding machine">grinding machine can be easily set-up without mechanical retooling.

Complete machining ensures process stability

Maximum quality while adhering to all tolerance specifications and the greatest process stability result in efficient truck camshaft machining. Bloemen confirmed:

"The modular and ergonomic design of the grinding machine and therefore the accessibility to the components are very important to us. For example the modular units for the hydraulic and coolant system. The associated flexibility and ease of maintenance were pivotal in DAF's decision to purchase," he said.

The installed in-process measuring systems ensure a precise profile contour on the cylindrical and non-cylindrical elements alike. These allow the data to be incorporated into the grinding process in real time. Even the smallest deviations are corrected immediately. The JUCAM machine runs fully automatically in continuous operation. The high-speed grinding machine is loaded by a robot and unloaded by a gantry loader.

Reliable, long-established partnership

Bloemen affirmed that they have implemented several projects together: "Junker is a reliable partner with a very good technical understanding who achieves its objectives at every stage in the project" he said. With a young, open-minded team, the truck manufacturer has been working with JUNKER for over 20 years and implements its projects using a constructive and targeted approach.