Fastems’ link between automation and sustainable manufacturing

Fastems’ link between automation and sustainable manufacturing

Through calculating its carbon handprint and footprint, Fastems has taken its first steps towards understanding how automation enables more sustainable product development and how to reduce the company's environmental impact.

-scaled-1024x905.jpg)

Through calculating its carbon handprint and footprint, Fastems has taken its first steps towards understanding how automation enables more sustainable product development and how to reduce the company's environmental impact.

In addition to these calculations, Fastems has mapped out how the three pillars of sustainability, namely the environment, the economy and the society can be supported through intelligent automation solutions.

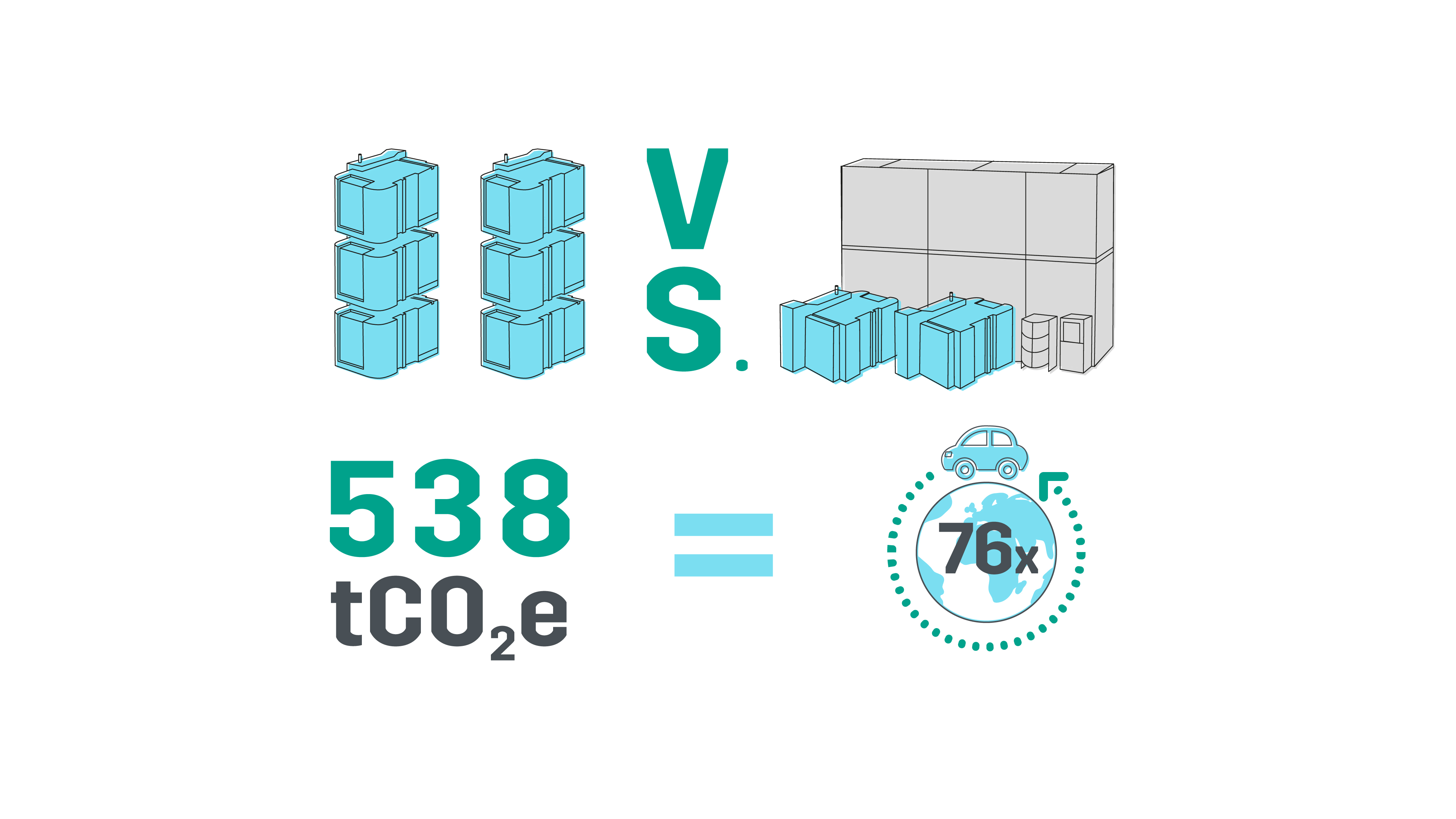

Together with Gaia Consulting, a leading sustainability agency, Fastems has modeled the mechanism that measures how much tCO2e, or tons of carbon dioxide equivalent, is saved through investing in an average Fastems flexible manufacturing system (FMS). This measurement is called the carbon handprint. According to these calculations, a user can save up to 538 tCO2e through the investment, which equals making 76 car trips around the globe.

"The effect is possible because automation can triple the utilization rate of machine tools," said Mikko Nyman, Fastems' CEO. "A typical non-automated machine tool cuts chips around 2,000 hours per year whereas an automated one can reach 6,000 – or even over 8,000 – yearly production hours. This means that instead of purchasing six non-automated machine tools, manufacturers can purchase two automated ones to achieve the same production capacity."

The figures represent the typical milling machine sizes integrated by Fastems and the typical emissions caused by their production, netted against the emissions caused by the production of the automation solution. Moreover, an estimate of 34 tCO2e is also being saved every year in heating (or cooling) costs because of saved floorspace.

For Fastems, these figures are part of a larger picture: "We're building a more sustainable future with and within manufacturing. To do so, we're helping manufacturers to work smarter when it comes to materials, energy, and people. We want to enable manufacturers to do what they do best, but by using less," said Nyman.

All this is possible because automation and digitalization enable greater resource efficiency, more timely production, less waste and improved quality. At the same time, work becomes more meaningful and safer for the operators involved. Automation helps make manufacturing competitive anywhere in the world; benefiting from strong manufacturing is a cornerstone for economic success in any nation, ensuring the well-being of people.

In addition to calculating its carbon handprint, Fastems has also calculated its carbon footprint, meaning the CO2-equivalent of emissions associated with the company's operations. This is an important step because once the numbers are known, they can be improved.

Regarding Fastems' direct emissions and those indirect emissions from purchased energy (GHG Protocol Scopes 1–2), the biggest share comes from consuming electricity and heat, which make up for nearly two-thirds of the company's carbon footprint. Now that scopes one and two have been calculated, Fastems' next step is measuring its indirect emissions (GHG Protocol Scope 3) beginning with business travel, and to set goals in 2021 to reduce its carbon impact.

"Business travel makes only a part of our indirect emission, it's one of the most substantial ones and once calculated during the fall of 2021, we'll know much more about our environmental impact as a whole and be able to set goals to reduce it," says Nyman and concludes: "The carbon hand- and footprint calculations, understanding the three pillars of sustainability and what they mean to us, as well as setting goals for the future are what allow us to build a more climate-friendly Fastems and manufacturing industry."

For more information about Fastems & Sustainability, see www.fastems.com/sustainability. For more information about carbon hand- and footprint calculations, contact marketing director Mikko Tuomaala at +358 50 441 4236 or [email protected].