Grinding machine maker utilizes German measuring technology

grinding-machine/" data-glossary-id="141847" data-glossary-teaser="Powers a grinding wheel or other abrasive tool for the purpose of removing metal and finishing workpieces to close tolerances. Provides smooth, square, parallel and accurate workpi…" title="Powers a grinding wheel or other abrasive tool for the purpose of removing metal and finishing workpieces to close tolerances. Provides smooth, square, parallel and accurate workpi…" aria-label="Glossary: grinding machine">Grinding machine maker utilizes German measuring technology

Seiwa Corp., the Japanese grinding machine maker, utilizes Liebherr measuring technology. Now Liebherr is offering Seiwa's grinding machines for its customers.

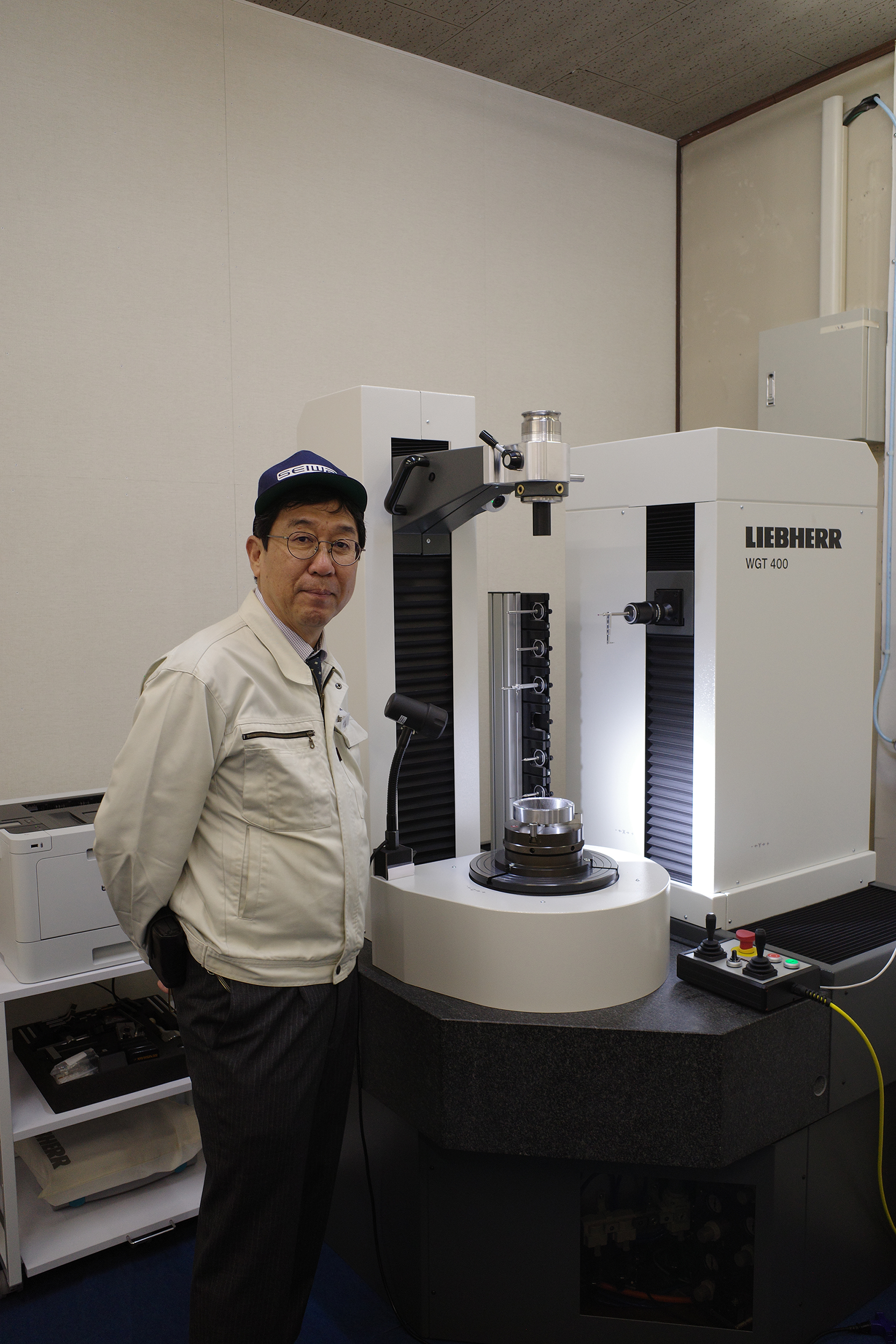

The Japanese Seiwa Corp. recently started using the Liebherr WGT 400 gear inspection machine to measure the tools that are used for its customers.

Seiwa, a manufacturer of machine tools for the gear industry, has gained confidence in the measuring instrument's precision. Conversely, Liebherr now offers Seiwa's tool grinding machines, to expand its product portfolio.

Liebherr opened its own sales office in Japan in 2015, and the contact between the two companies was brought about by Kiyoshi Iguchi, Director Sales & Service at Liebherr in Japan. Toshihiko Tatsu, the president and majority shareholder of Seiwa, was won over by Liebherr's presence as a complete provider of tools, machines, and technology as well as the quality and precision of Liebherr's measuring technology, the company says. Peter Wiedemann, managing director of Liebherr-Verzahntechnik GmbH, expects new impulses for international business to result from the sales partnership: "For us," he said, "the strategic partnership with Seiwa is a springboard into new markets, which we are happy to use."

The WGT 400 – universal and accurate

Since March 2021, quality control of the tools used by Seiwa has been carried out on the WGT 400 gear inspection machine by Liebherr. It is also available there for tests and customer presentations.

The WGT 400 is a universal gear inspection machine that is suitable both for gear and for tool measurement and provides a high-quality alternative to other common inspection machines.

Lapped granite guides, air bearings, precision rotary tables, and Renishaw probe systems ensure the mechanical precision of the machine. On the WGT, any type of gear, shaft geometries, gear cutting tools, and other rotation-symmetrical workpieces can be measured – individually configured by Liebherr according to user requirements. Each model fulfills the quality standard of group 1 according to VDI/VDE 2612/2613 and measures gears from a module of > 0.12.

The machines are installed and commissioned on-site by Liebherr service specialists. In addition, training that has been tailored to the specific customer is provided, as well as service support packages. The WGT is equipped with an extensive software package that includes gear and tool measurement and also integrated chamfer measurement. The measuring results can be evaluated according to the different country-specific norms – for example, according to JIS in Japan or AGMA in the USA.

Customer benefit for both sides

Toshihiko Tatsu said he expects the Liebherr gear inspection device will optimize the precision and quality of the measurement of tools used to machine small parts.

"We are currently putting a lot of work into machines for the production of internal gears and gears with very small modules," he said. "We are also hoping for an increase in efficiency due to the WGT 400's high measuring speed. The supply of data in real-time is a real advantage: Since our largest customer, Honda, also uses a WGT 400, this will make the exchange of data a lot easier."

Liebherr, in turn, is expanding its product portfolio with tool grinding machines: The grinding machine from Seiwa's Fabris product line sharpens the hobs for the machining of straight and helical gears. Until now, Seiwa machines have been well-known in the Asian market, where their stability and precision are valued by manufacturers and users. Liebherr customers will now also benefit from this: "We are taking this step because we are convinced of the quality of Seiwa's machines", said Kiyoshi Iguchi.

Iguchi also has confidence in the company: "Seiwa is an agile, pragmatic company with a hands-on mentality, close customer contact and lots of experience – small but fine, and well connected in the Japanese gear world."

Both Liebherr and Seiwa view themselves as innovative solution providers focusing on the customer and their requirements. When asked what he particularly values about Liebherr, Toshihiko Tatsu says: "The foreman system in Germany stands for the craftsmanship which is greatly valued in Japan. I am impressed by the quality awareness of the Liebherr technicians and always have the feeling that one can learn a lot from them. This is probably the factor that makes Liebherr a top brand."