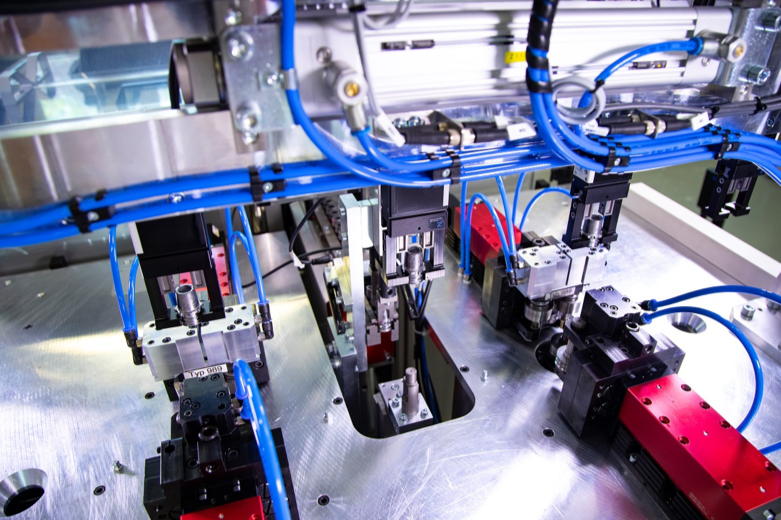

Grippers grasp battery terminals during burnishing operation

Grippers grasp battery terminals during burnishing operation

A Russian battery maker was looking to automate its manufacturing process and turned to Wenaroll in Solingen, Germany, experts in burnishing technology, to develop a turnkey production system.

A Russian battery maker was looking to automate its manufacturing process and turned to Wenaroll in Solingen, Germany, experts in burnishing technology, to develop a turnkey production system.

The application required the design and manufacture of an automatic battery terminal burnishing machine, which uses roller burnishing to compress the surface of lead alloy battery terminal. A key component of the burnishing system were grippers that gently, but securely, held the terminals for burnishing. Overall, the burnishing system comprises a frame, drive unit, machine base, roller units, gripper systems, feeding and sorting system and a control system complete with an operator interface.

The process begins with the presentation of the battery terminals from the feed unit. A Zimmer gripper unit then transports the terminals to the roller units where the actual burnishing process occurs. After the terminals are clamped and rotated into position, the roller units move together, and the designated surfaces are hardened by the burnisher rolls applying a pre-defined amount of force. The roller burnishing process takes place at a maximum force of 255 newtons and a maximum speed of 400 rpm.

These forces produce terminals that are gas-tight and have a surface with a roughness depth of Rz < 1 µm, with the processing time just 8 seconds per battery terminal.

The turnkey machine utilized four Zimmer grippers mounted in parallel on an aluminum frame, is one of the key components of the system. Zimmer Group UK's Ian Sinclair said the customer had particular specifications for the project. "The preference was for electric grippers with a single cable solution," said Sinclair. "It was essential that the grippers applied the smallest possible gripping force to prevent damage to the delicate surface of the lead battery terminal and to ensure that no defects would be left behind on objects being handled."

A further requirement was the capability to use long gripper jaws or gripper fingers, as for certain components, the design required the option to insert gripper fingers deep into the device.

Four models of Zimmer's GEP2000 series (GEP2010IO-05-A) were specially selected for this application. The electrically driven small-part grippers are easy to control and were primarily designed for handling small parts, such as the battery terminals. This series of grippers series offer adjustable gripping forces between 40 N and 500 N and jaw strokes between 6 and 16mm. In addition, the grippers feature a mechanical self-locking mechanism that prevents the loss of the battery terminals in the event of power failure.

Other features that help ensure reliability include gripper housings that are manufactured from hard-anodized aluminum, and guides that rely on a flat guide that has been tried and tested for decades. These features combined allow 10-million cycles to be handled without the need for maintenance.

The four individual grippers are not all that Zimmer Group delivered to Wenaroll for this application. Zimmer's in-house Systems Department also developed and fabricated the complete gripper unit including the frame structure and wiring.

The Zimmer Group (UK) Ltd. be reached at +44 1283 542103 or by visiting https://www.zimmer-group.de/en