High speed steel cutting tool market to hit $16.8 billion

High speed steel cutting tool market to hit $16.8 billion

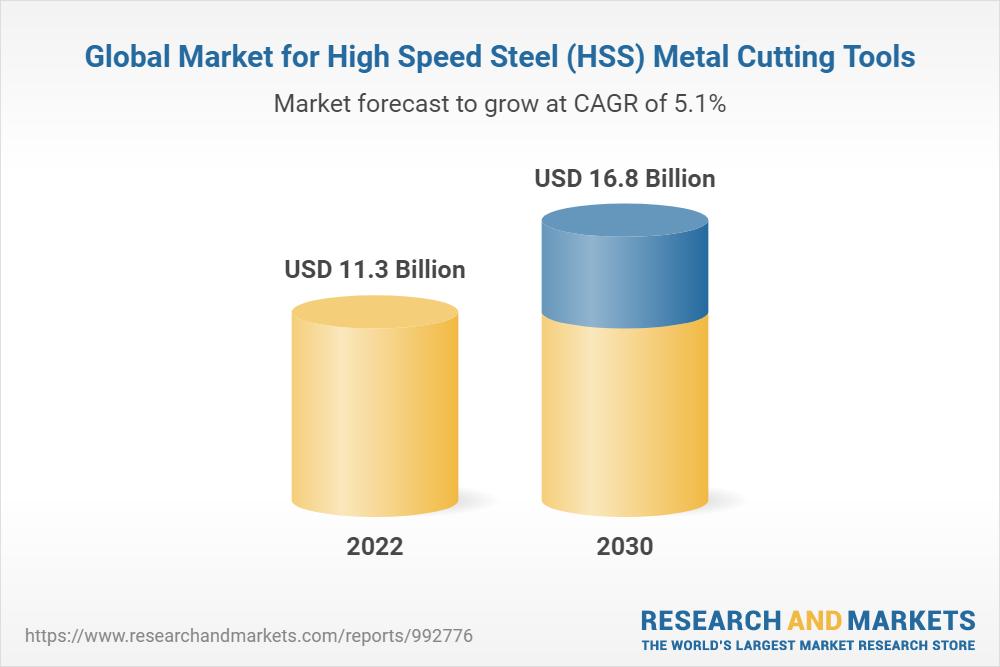

The global market for high speed steel (HSS) metal-cutting tools estimated at $11.3 billion in the year 2022, is projected to reach a revised size of $16.8 billion by 2030, growing at a CAGR of 5.1% over the analysis period 2022-2030.

The global market for high speed steel (HSS) metal-cutting tools estimated at $11.3 billion in the year 2022, is projected to reach a revised size of $16.8 billion by 2030, growing at a CAGR of 5.1% over the analysis period 2022-2030.

HSS Tapping Tools, one of the segments analyzed in the report, is projected to record a 5.5% CAGR and reach US$6.9 Billion by the end of the analysis period. Taking into account the ongoing post pandemic recovery, growth in the HSS Milling Tools segment is readjusted to a revised 4.6% CAGR for the next 8-year period.

U.S. market estimated at $3.1 billion, China forecast to grow at 8.6% CAGR

The high speed steel (HSS) metal-cutting tools market in the U.S. is estimated at $3.1 billion in the year 2022. China, the world's second largest economy, is forecast to reach a projected market size of $3.7 billion by the year 2030 trailing a CAGR of 8.6% over the analysis period 2022 to 2030.

Among the other noteworthy geographic markets are Japan and Canada, each forecast to grow at 2.6% and 4.2% respectively over the 2022-2030 period. Within Europe, Germany is forecast to grow at approximately 3.3% CAGR. Led by countries such as Australia, India, and South Korea, the market in Asia-Pacific is forecast to reach US$2.3 Billion by the year 2030.