KUKA’s automated solutions on display at IMTS 2024

KUKA’s automated solutions on display at IMTS 2024

At IMTS 2024, KUKA Robotics will demonstrate a variety of special automated solutions from several of its system partners that streamline part processing and boost overall production output.

At IMTS 2024, KUKA Robotics will demonstrate a variety of special automated solutions from several of its system partners that streamline part processing and boost overall production output.

Those innovative systems, all featuring KUKA robots in booth 236807, will include the CyberDrawers machine feeding unit from Waybo; entry-level machine and process automation from Mairotec GmbH; automated milling from Robotics Solutions Inc.; and metal additive manufacturing from One-Off Robotics. For part fabrication operations, show attendees will also experience the Mobile Robotic Bending Cell from Bystronic and the Robotic Bending Cell (RBC) from the Gladwin Automation Division.

Waybo CyberDrawers

For turnkey machine tool automation solutions, Waybo's CyberDrawers feeding system is well suited for turning centers and milling machines. Shops can program the system using a simple, internally designed interface that calculates nearly all the robot's movements, and setting up for a new production process is quick and easy. Initial installation of the whole system typically takes only a day.

All Waybo products, including the CyberDrawers are fully modular, compatible with each other and optimize operations while reducing production costs. The cells integrate with both current and older machine tools and interface with other equipment such as marking machines, digital inspection machines, saws, grinding wheels and more.

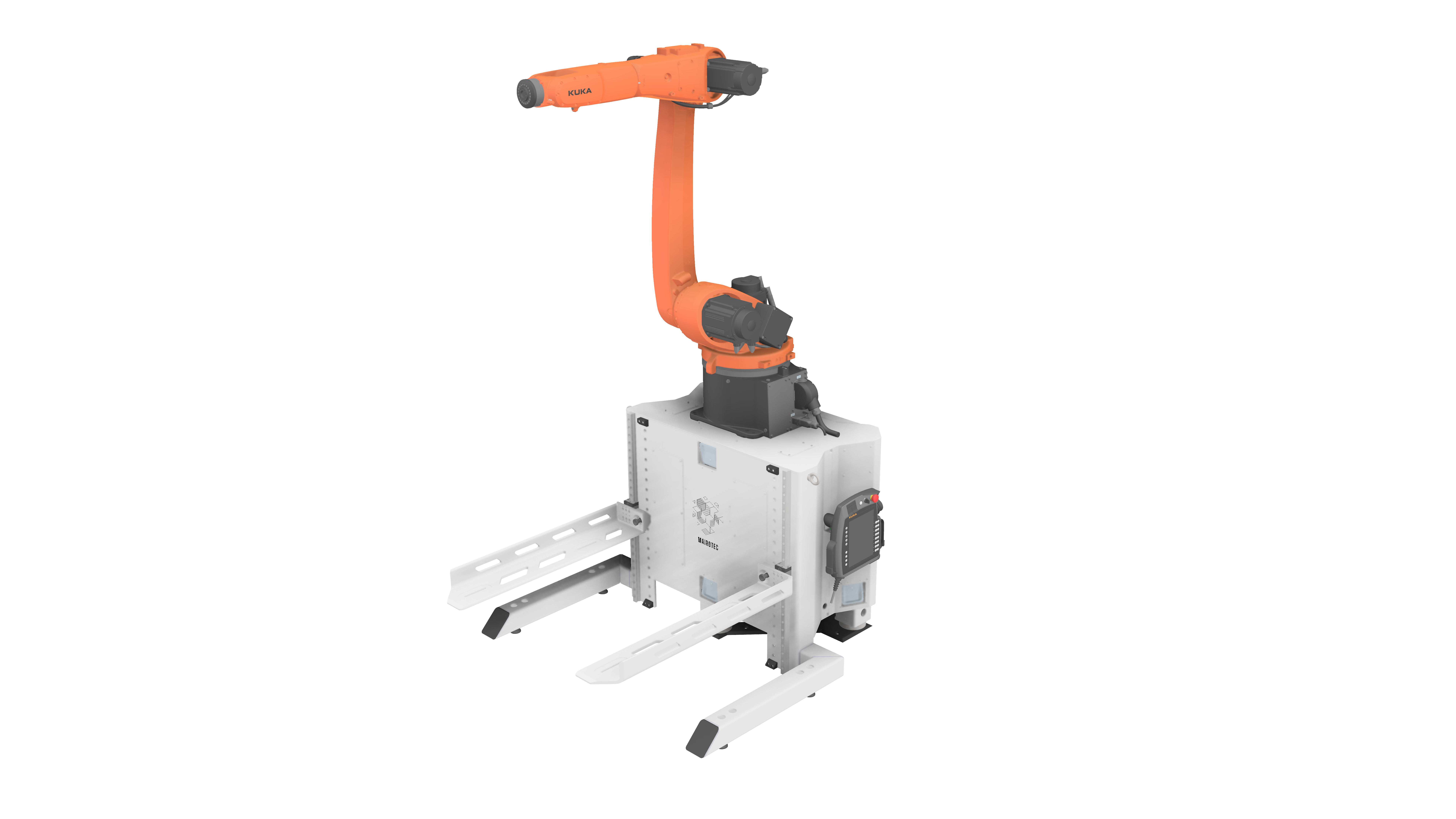

MairoFlex Compact 8

Mairotec

Whether an application involves a machine or process, standard systems from Mairotec are flexible, provide easy entry into automation and are an economical alternative to larger size systems. During IMTS, the company will show its cost-effective MairoFlex Compact 8. The MairoFlex Compact 8 offers the speed and flexibility of an industrial robot, with the benefits of a fenceless solution.

The unit provides a reach up to 1640mm, increased speeds and high pose repeatability. Its integration with the KR C5 micro controller from KUKA ensures maximum performance, connectivity and flexibility. The KR C5 micro integrates seamlessly into existing infrastructures and immediately delivers added value through efficient performance for all applications, and it is highly capable for those users with more sophisticated requirements. Mairotec also incorporates KUKA LBR iisy cobots into its MairoFlex iisy solution that maximizes flexibility, minimizes space requirements, boosts performance, accelerates production and lowers total cost of ownership.

Designed with universal applicability for almost all market segments, especially for pick-and-place operations in machining, assembly and handling applications, the MairoFlex iisy is easy to teach, so previous robotics knowledge is often unnecessary. No-code programming enables beginners to achieve fast initial success, while the LBR iisy cobot is extremely easy to use.

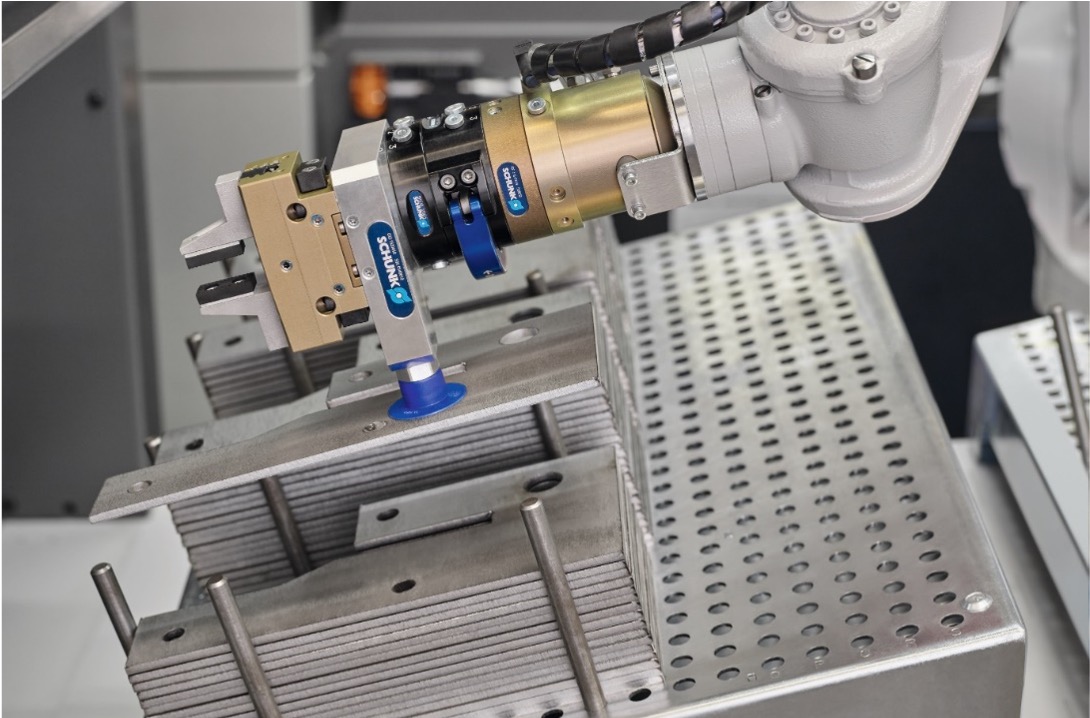

Robotic Solutions

As a company that specializes in custom robot systems, Robotic Solutions will show a robotic milling application that uses a KR Quantec Nano robot and DKP 3 positioner that is processing a cast part made of hard material.

The turn-key solution offers users full CNC-type operations including automated tool changers, tool pre-setters, hotwire harps, probes, 3D scanners, and unlimited file size capabilities. The company's systems are available in sizes ranging from small to large to fit a shop's specific robotic needs.

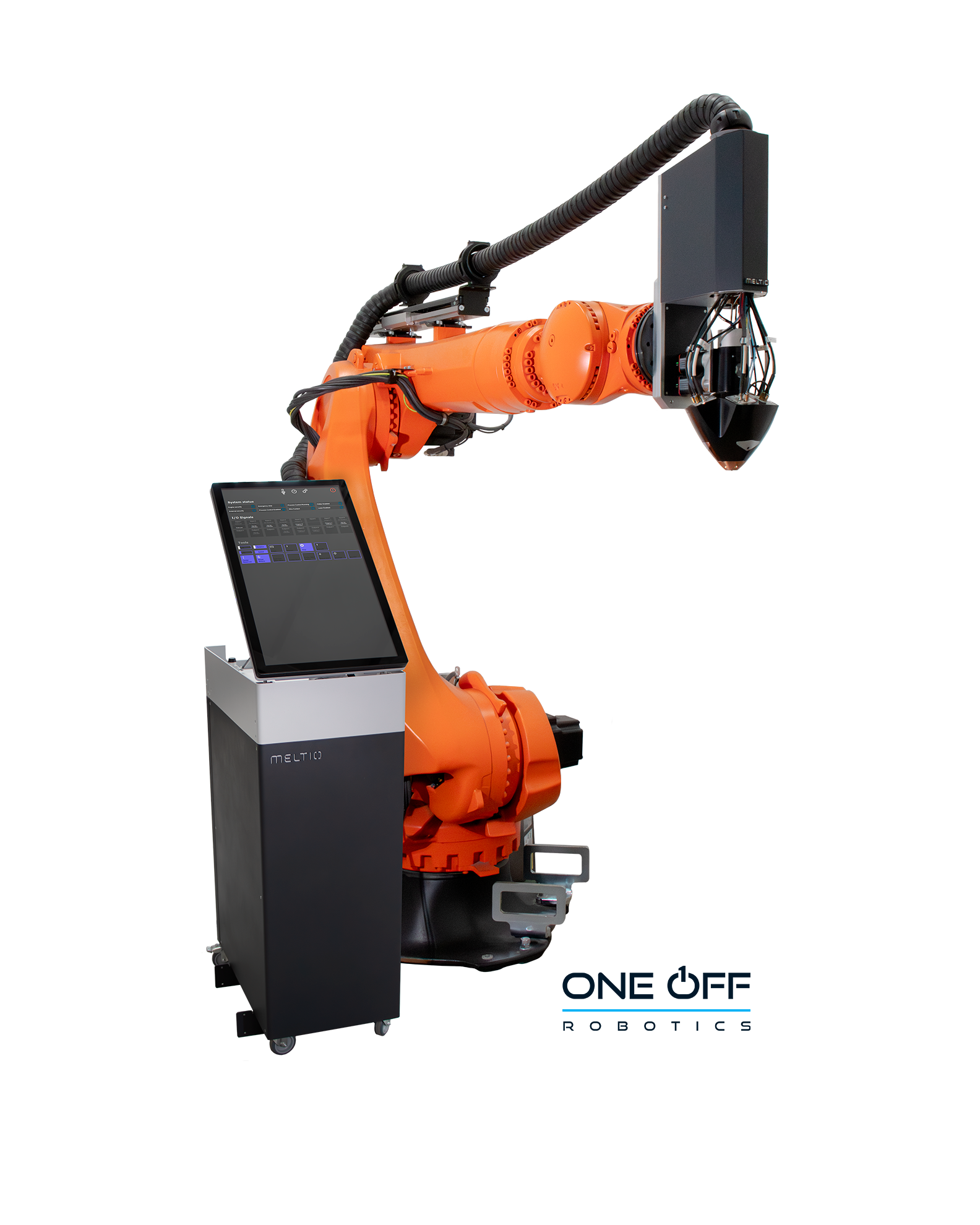

One-Off Robotic's Meltio bot

One-Off Robotics

how attendees looking to incorporate metal additive technology into their part processing operations will experience the Robotic Metal Additive Manufacturing System from One-Off Robotics in the KUKA booth. These state-of-the-art systems that use KUKA robots are designed to revolutionize the production capabilities of the defense, aerospace, research and specialized production sectors.

With improved speed, precision and flexibility, One-Off Robotic systems address not only the current needs of the industry but also lay the groundwork for future advancements. The system featured at the show provides high efficiency and supports average deposition rates of 4kg/hour for wire arc additive manufacturing (WAAM) and variable rates – up to 10kg/hour – for wire laser additive manufacturing (WLAM), ensuring rapid production cycles in both applications. Enhanced control over the melt pool and part density improves the mechanical properties of final products.

Bystronic

Bystronic

For those shops struggling with limited floorspace, the Bystronic Mobile Bending Robot Cell provides highly flexible on-demand automation specifically designed for confined spaces and for producing small and medium-sized parts more conveniently than ever. Using a KR AGILUS robot from KUKA, the miniature-format press-brake cell delivers bending speeds of up to 30mm/second – a speed that's three times faster as compared to large press brakes.

In just a matter of minutes, the company can expand either its compact ByBend Star 40 or ByBend Star 80 press brakes into mobile bending cells for manual or automatic operation. This gives shops the flexibility to select the right cell for their particular part bending application.

Gladwin Aiutomation

Gladwin Automation

Ease of use and flexibility are at the heart of Gladwin Automation's RBC that requires little input from press brake operators while also allowing shops to handle a variety of bending jobs. Equipped with all necessary components – from press brake, robot and end-of-arm tooling to offline programming software and material handling conveyors – the cell provides a viable way to maintain or increase output without the effort and expense of additional labor.

The cell increases productivity through 24/7 operation, eliminates the need for heavy lifting by operators, improves overall part quality and reduces the risk of scrapped parts. Plus, the cell's easy-to-use interface makes operating and retooling fast and intuitive.