Machine tools at the edge of the Industrial Internet of Things

Machine tools at the edge of the Industrial Internet of Things

As Industry 4.0 and the Industrial Internet of Things (IIoT) continue to grow and evolve, they promise numerous benefits for a leaner enterprise. In the realm of machine tools, the IIoT can certainly offer chances for improvements in monitoring and maintenance. There are, however, some concerns that must be addressed before this becomes a reality.

As Industry 4.0 and the Industrial Internet of Things (IIoT) continue to grow and evolve, they promise numerous benefits for a leaner enterprise. In the realm of machine tools, the IIoT can certainly offer chances for improvements in monitoring and maintenance. There are, however, some concerns that must be addressed before this becomes a reality.

Foremost is the need for more "smart" devices and machine components that communicate with each other and the factory. Machine tool manufacturers seek to use such components to make their products more reliable and productive, without increasing initial machine cost. This situation is driving a trend of increased cooperation between end users, machine design engineers and their engineering partners in electro-mechanical and pneumatic motion components.

Photo courtesy of Haas Automation Inc.

Photo courtesy of Haas Automation Inc.

Alliance of Experts

The end goal is to offer useful information to factory managers who can act on the data that machines collect. Considering this, all partners must work together to set up effective IIoT-capable systems. End users know what information they need for their businesses. Machine designers know the unique concerns and opportunities present in a particular application. Automation component suppliers know how to get data from edge devices to factory software and the internet. Together these engineers can create systems that help factories achieve a leaner, more automated business.

These alliances work to find automation solutions that cost-effectively incorporate better connectivity, control and intelligence into machine tools. Engineering partners can make sure that all collected data is accurate and that it represents important parameters relevant in the real world. They can specify which components to use and which communications protocols make sense for a given application.

Take, for example, a pneumatic tool used to grasp blank parts and load them into position on a cutting machine. Its pneumatic valves are controlled by solenoids, and the voltage of the coils can be monitored for signs of impending failure. To make this data actionable, machine designers need a means of acquiring that information. Open-standard protocols such as IO Link provide affordable serial communication with low-level edge devices, connecting them to motion controllers which in turn connect to the factory network and, if desired, to an internet gateway. Motion component manufacturers are starting to offer IO Link modules for their pneumatic valves, providing an easily integrated, cost-effective solution.

More Than Just Sensors

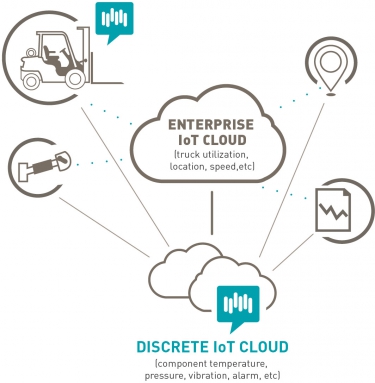

The IIoT goes beyond merely connecting together sensors and factory management software. Rather, it is an approach that allows the collection and effective interpretation of data.

So far, the status quo in industrial equipment and machine tools has been to monitor one or two aspects of a system, such as position or speed. However, tracking the number of cycles could supply business managers with data that is important for measuring production, service life and total cost of ownership. Other parameters such may allow engineers to spot when equipment is not operating correctly or as efficiently as it could. Managers can then schedule maintenance predictably and prevent small problems from becoming big headaches.

A good example is a motor that powers the position of a cutting tool. In the past, the motion controller or PLC received only speed and position information from the motor and its encoder. Now it must be able to receive information about errors, temperature and power factor. Most PACs (programmable automation controllers) are able to handle these inputs and provide the logic that determines when to send a maintenance alert. Some PACs even have internet gateways as part of their embedded HMIs (human-machine interfaces). This greatly simplifies the programming required to connect machines to the internet.

Growing Acceptance

As industry continues to move into the 21st century, the demand for automated, intelligent equipment and controls is sure to expand into machine tool applications, as well as transportation, energy, food and beverage, and life sciences. Each of these applications has its own set of unique requirements. For example, food and beverage applications require absolute cleanliness and frequent, periodic maintenance, whereas transportation applications require long operating times and harsh, continually varying environments. For machine tools, the approach marries the muscles of machines with intelligent motion control, and then shares information about machine health and production with the entire enterprise.

As mentioned, the IIoT is a highly integrated approach to industrial applications, machine tools and operations. It requires collaboration on many levels between machine tool builders, motion control suppliers, sensor manufacturers, infrastructure vendors and machine end users. When each partner offers the essential expertise needed, then machine intelligence can be applied to many different kinds of processes and business goals.