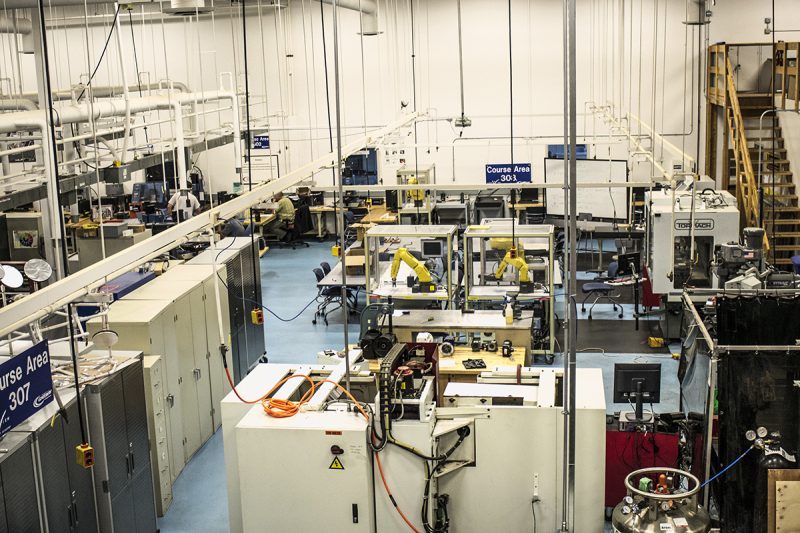

Digital Manufacturing and Design Innovation Institute opens its manufacturing floor to the community

The Chicago-based Digital Manufacturing and Design Innovation Institute is opening its manufacturing floor to manufacturers and academic institutions that need to quickly test process improvements. "We are seeing a manufacturing renaissance in Chicago, and the Digital Manufacturing and Design Innovation Institute is adding to that momentum," Mayor Rahm Emanuel said. "By opening their doors, sharing equipment and providing expertise to small businesses, startups and students, DMDII is ensuring Chicago's advanced manufacturing ecosystem will be stronger for generations to come."