Report predicts steady growth for waterjet cutting machine market

Report predicts steady growth for waterjet cutting machine market

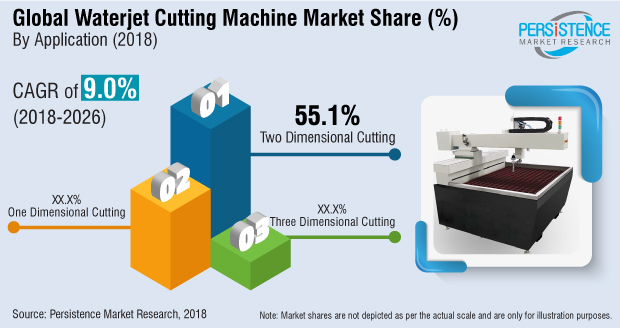

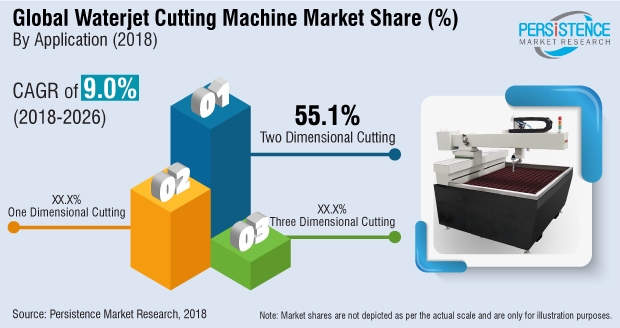

According to a findings specified in the report on the waterjet cutting machine market, the market is expected to witness steady growth over the forecast period (2018-2026), led by increasing industrialization and manufacturing sector in emerging regions across the globe. The long-term outlook for the global waterjet cutting machine market is expected to remain positive and the market is expected to expand at a CAGR of 9.0% during the forecast period.

Article from Persistence Market Research

According to a findings specified in the report on the waterjet cutting machine market, the market is expected to witness steady growth over the forecast period (2018-2026), led by increasing industrialization and manufacturing sector in emerging regions across the globe. The long-term outlook for the global waterjet cutting machine market is expected to remain positive and the market is expected to expand at a CAGR of 9.0% during the forecast period.

Global Waterjet Cutting Machine Market: Dynamics

Waterjet cutting has emerged as a versatile, cost-effective and accurate alternative to conventional cutting methods such as plasma, milling machines, lasers and EDM for many applications. Waterjet cutting machines find applications in many industries such as metalcutting, automotive, aerospace, defense, semiconductors, disposable products, food, glass, ceramics and paper. This process cuts material without creating heat or any mechanical stress. Waterjet cutting offers certain green benefits as this is a cold cutting process, which eliminates waste and slag deformation. This cutting technology offers great accuracy, productivity and efficiency. That apart, waterjet cutting machines are more economical than laser machines. Abrasive jets are faster than EDM, which removes metal at a comparatively slow rate. In comparison to plasma cutting, waterjets operate at a much lower temperature and there is no heat affected zone while the material is being cut with a waterjet cutting machine. These are some of the factors positively impacting the growth of the waterjet cutting machine market.

Global Waterjet Cutting Machine Market: Segmentation Overview

- On the basis of pump type, the waterjet cutting machine market has been segmented into direct-drive pump and intensifier pump. The intensifier-pump segment dominated the global market in 2017 and the segment is estimated to witness relatively high growth during the forecast period, which can be attributed to the higher efficiency and ability to deliver higher pressure as compared to direct-drive pumps.

- On the basis of application, the 2D cutting segment is estimated to witness significant growth during the forecast period, due to the high demand for the metal fabrication industry.

- On the basis of pressure range, the waterjet cutting machine market has been segmented into up to 4,200 Bar and more than 4,200 Bar.

- On the basis of end use, the metal fabricating segment is dominating the market, followed by automotive and ceramics.

Global Waterjet Cutting Machine Market: Regional Overview

North America, followed by Europe, dominated the global waterjet cutting Machine market in 2017. SEA and Pacific and China are expected to be the most lucrative regions for the growth of the waterjet cutting machines market and these regions are creating significant opportunities for the manufacturers of waterjet cutting machines. Furthermore, increasing investment in automotive and manufacturing sectors in emerging regions creates a significant opportunity for the waterjet cutting machine market. Additionally, the waterjet cutting machine market is expected to witness significant growth in developed economies over the forecast period, owing to the healthy growth of construction and metal fabrication industries.

Global Waterjet Cutting Machine Market: Vendor Insights

The report highlights some of the leading companies operating in the global waterjet cutting machine market, such as A Innovative International Ltd., Caretta Technology s.r.l., CMS Industries, Dardi International Corp., Flow International Corp., Foshan Yongshengda Machinery Co. Ltd., H2O Jet, Hornet Cutting Systems, Hypertherm Inc., International Waterjet Machines, Jet Edge Inc., KMT Waterjet, Koike Aronson Inc., Metronics Technologies S.L., Omax Corp., Plasma Automation Inc., PTV, spol. s r.o., Semyx LLC, STM Stein-Moser GmbH, Sugino Machine Ltd., Techni Waterjet, TrennTek GmbH, WardJet and Waterjet Sweden.