Schaller Group off to races with new CNC technology

Schaller Group off to races with new CNC technology

The Schaller Group, a Michigan-based metal forming company, invested in CNC technology to drive growth in the family-owned company and support the company principle's passion for hydroplane racing.

Speed, power and precision are coveted qualities to Justin and Maryann Schaller, both in terms of the Schaller Group family-owned business and in shared passion of hydroplane racing. The Starrag's STC 800X is playing a role in both the business and racing endeavors.

Speed, power and precision are coveted qualities to Justin and Maryann Schaller, both in terms of the Schaller Group family-owned business and in shared passion of hydroplane racing. The Starrag's STC 800X is playing a role in both the business and racing endeavors.

The brother and sister duo have executive positions with the Schaller Group, a third-generation, Michigan-based precision metal forming and assembly company that manufactures parts found in the aerospace, military, automotive and medical industries.

For 10 years, the Schaller siblings ran their own CNC machining company but in 2018 opted to bring their expertise back into the family-owned stamping business. The company expanded one of its plants to 90,000-square-feet. Designated for CNC machining, it is one of six specialized manufacturing plants operated by the Schaller Group in the Detroit area.

Complex aluminum workpieces

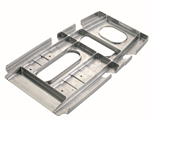

The STC 800X is ideally suited for machining complex aluminum workpieces due to its precision capabilities and axis configuration. Being capable of continuous 5-axis milling with the use of a rotary table and a 120-kW tilting spindle (S1), Schaller is able to machine with up to 162 horsepower and 30,000 revolutions per minute.

With the A-axis range of -100/+60 degrees, no angle heads are necessary for machining aerostructures. The rotary table allows the economical machining by using a tombstone setup or multiple parts and fixtures on the same table. Additionally, the STC at Schaller has been integrated into a manufacturing system.

With the A-axis range of -100/+60 degrees, no angle heads are necessary for machining aerostructures. The rotary table allows the economical machining by using a tombstone setup or multiple parts and fixtures on the same table. Additionally, the STC at Schaller has been integrated into a manufacturing system.

The STC 800X has unique features like a 30,000 RPM, 162 continuous horsepower spindle, an all-steel gear A-axis, and standard pallet changing. Other key features for optimum aluminum machining include ambient temperature-controlled coolant, vacuum clamping, automated part measurement and automated machine calibration.

Speed, power and precision.

"This is the perfect machine for our growth plans," said business development specialist Maryann Schaller. "We recently poured the foundation to add a second STC 800X to our operation, and because we purchased a Flexible Manufacturing System (FMS) with the first STC 800X, we have the ability to have multiple machines in a single manufacturing line."

One example of new opportunities is medical devices. In March of 2020, Schaller Corporation manufactured and donated parts for a prototype ventilator project at a University in the hopes of helping with the COVID crisis. And while that project did not take off as hoped, it showed Schaller another market where the precision and speed of the Starrag STC 800X will be greatly beneficial.

One example of new opportunities is medical devices. In March of 2020, Schaller Corporation manufactured and donated parts for a prototype ventilator project at a University in the hopes of helping with the COVID crisis. And while that project did not take off as hoped, it showed Schaller another market where the precision and speed of the Starrag STC 800X will be greatly beneficial.

"The speed and accuracy of these machines were big reasons why we chose Starrag," she said,

Buyer's journey was seamless

Schaller Group Chief Technologist Justin Schaller was introduced to Starrag product at the International Manufacturing Technology Show (IMTS. "When the right project came along in 2020, it provided us the opportunity to purchase the Starrag STC 800X," he said.

The foundation was poured and installation was completed in September 2020. However, the project was put on hold because as its customer changed direction to produce pandemic-related products.

Starrag North America Sales Director Tim Mooney. "The STC 800X is ideal for machining 55" or smaller precision parts, which is what Schaller needs for the complex aerospace, defense and specialty industry markets it is expanding into."

Diversify into high performance racing

One such growth area being pursued is high performance racing where CNC machining is combined with the Schallers' love of racing. High performance racing includes watercraft like hydroplanes and sleek offshore boats as well as various forms of auto racing like stock, drag and rally racing. All rely on quality-built aluminum parts.

According to Maryann Schaller, "the Starrag STC 800X is the perfect machine for our expansion into the high-performance racing industry. Our experience racing hydroplanes has introduced us to a network of potential customers. The speed of the machine along with the ability to utilize tombstones on a multi-pallet system will allow us to be competitive in the manufacturing of engine blocks, heads, manifolds and other performance racing products."