Shop grinds out niche and soars beyond the competition

Shop grinds out niche and soars beyond the competition

Many manufacturers in the aerospace industry depend on high-precision, complex specialized cutting tools and want them as quickly as possible. However, not all tool grinding shops can meet that challenge. Almar Tools Inc., Camas, Wash., is one that can. To succeed where others often fail, the shop takes a simple straight-forward three-prong approach that consists of efficient production practices and highly trained machinists paired with the latest in tool grinding wheel or other abrasive tool for the purpose of removing metal and finishing workpieces to close tolerances. Provides smooth, square, parallel and accurate workpi…" title="Powers a grinding wheel or other abrasive tool for the purpose of removing metal and finishing workpieces to close tolerances. Provides smooth, square, parallel and accurate workpi…" aria-label="Glossary: grinding machine">grinding machine technology.

Article is from UNITED GRINDING

Many manufacturers in the aerospace industry depend on high-precision, complex specialized cutting tools and want them as quickly as possible. However, not all tool grinding shops can meet that challenge. Almar Tools Inc., Camas, Wash., is one that can. To succeed where others often fail, the shop takes a simple straight-forward three-prong approach that consists of efficient production practices and highly trained machinists paired with the latest in tool grinding wheel or other abrasive tool for the purpose of removing metal and finishing workpieces to close tolerances. Provides smooth, square, parallel and accurate workpi…" title="Powers a grinding wheel or other abrasive tool for the purpose of removing metal and finishing workpieces to close tolerances. Provides smooth, square, parallel and accurate workpi…" aria-label="Glossary: grinding machine">grinding machine technology.

On a daily basis, Almar Tools faces multiple new requests for custom tooling solutions. Most job turnaround times are a couple weeks, but if needed, the shop can complete and ship hot jobs within a few business days. This is in contrast to large cutting tool OEMs that can take up to 10 weeks just to create a quote for a special tool order.

Photos courtesy of UNITED GRINDING

Almar Tools' 16 employees are masters in high-quality cutting tool manufacturing. Most have been with the company for over a decade, and some over 20 years. While such skilled labor is hard to come by, Almar fosters the growth and development of its highly trained personnel through both in-house and external training. The shop's grinding operators, in particular, have to learn on the job because there is no other way to achieve the necessary levels of expertise for the sophisticated tools the shop produces.

"But all the experienced machinists in the world could not create specialty precision cutting tools without equally precise tool grinding machine technology," said Marcelo Heredia, vice president of Almar Tools Inc. "That is why we have always relied on WALTER CNC tool grinding machines from UNITED GRINDING."

Marcelo and his brother Alex Heredia, president of Almar Tools, took over the shop from their father. He opened the shop in 1980 after coming to the United States from Argentina in 1968 as a manual tool grinder to help fill the skills gap that was left by men going to fight in the Vietnam War. When the company started out, it focused only on resharpening cutting tools on manual grinders.

The Heredia brothers added the shop's first CNC tool grinder, a WALTER 400, which, at the time, was the first of its kind on the entire West Coast. Its capabilities astonished them, and they immediately realized the opportunities to expand into the custom tools market. Within 30 days of using the new WALTER machine, they ordered a second one.

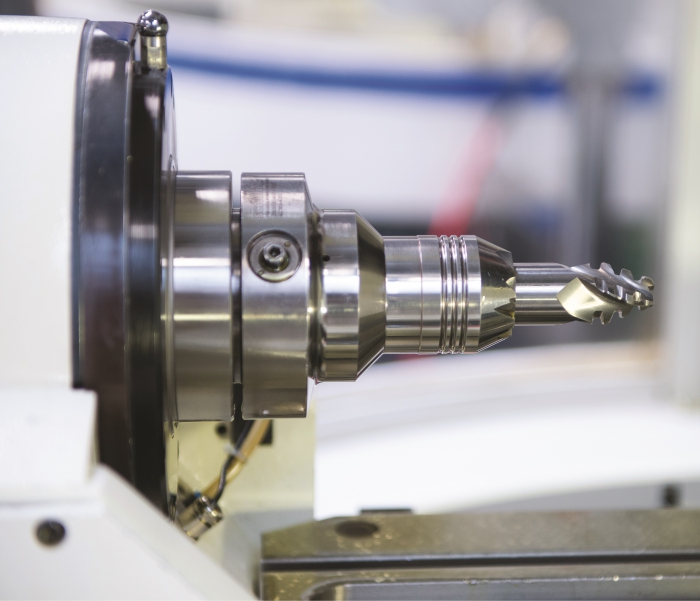

The WALTER 400s are gone, but Almar Tools currently has six WALTER HELITRONIC POWER CNC tool grinders. The machines deliver high performance because of their precise linear and rotating axes and robust solid cast iron gantry constructions. They also feature HELITRONIC ToolStudio CAD/CAM software that streamlines programming and provides essential simulation capabilities.

At Almar Tools, the shorter the job setup time, the better. And with its WALTERs, the shop can set up a job for a standard end mill in as little as 10 minutes and more complex jobs in under an hour. This capability, according to Heredia, makes Almar about three times faster than the competition and added that the shop has a customer in Texas that feels like Almar Tools is right around the corner because they get their tools so quickly.

As a key contributor to shorter job setup times, Almar Tools' HELITRONIC ToolStudio CAD/CAM software quickly creates grinding programs. The software also helps significantly improve overall shop efficiency by systematically processing jobs in their entirety from tool design and programming to grinding simulation and production. High-value carbide tool blanks often undergo several steps of complex machining prior to grinding. To protect the blanks, Almar Tools fully simulates the process before a grinding wheel ever touches one.

Almar Tools runs two shifts on its WALTER HELITRONIC POWER grinders. Consistency across equipment not only allows operators to jump from one machine to another, it makes maintenance and service easier for the shop.

Each of the shop's dual-spindle HELITRONIC POWERs accommodates up to six grinding wheels. With this capability, the machines grind extremely complex geometries within single-clamping cycles. The shop uses both spindles for the majority of jobs, and often up to four separate grinding wheels are required to complete one complex cutting tool.

Two of the shop's HELITRONIC POWERs feature an Eco loader flexible tool loading system mounted to the work table that further increases each machine's productivity. A gripper integrated directly into the grinding head allows the system to quickly load and unload tools to shorten overall cycle times and automate that process.

While aerospace is Almar Tools' main market, the shop also provides cutting tools for customers in the automotive, medical and electronics industries, and growth for the shop has been steady for many years. Recently, however, the shop found it had expanded as far as capacity would allow, so it opened a new facility that has more space for additional equipment and for supporting a potential product line of specialty cutting tools.

Marcelo and his brother Alex both agree that survival in the custom tool business takes years of experience on the part of a shop and its employees. On a daily basis and job after job, Almar Tools continuously proves that it has the know-how and grinding machine technology to deliver the high-quality, precise cutting tools that its customers need.

Almar Tools Builds a Better Quote System

Almar Tools Inc. realized long ago that fast job quotes are just as critical as advanced cutting tool grinders for meeting tight delivery schedules. To streamline the order-and-quote process, the shop developed its own paperless custom system called Tool Builder that lets customers easily enter tool data and the shop to then quickly quote the job – practically instantaneously.

According to Alex Heredia, president of Almar Tools Inc., the shop was the first of its kind in the country to develop such a paperless ordering system software.

At Almar Tools' website, customers fill in their desired specifications for a variety of predetermined cutting tool shapes or submit a CAD file or PDF print for their own completely custom tool. Once a customer sends information through the site, it stores their information, which makes subsequent orders even faster and more convenient.

After a customer print is received through Tool Builder, Almar Tools responds within a couple hours with a quote and design. The shop then manufactures a tool that will do exactly what the customer wants it to.