Studer hosts Motion Meeting 2026 press conference

Studer hosts Motion Meeting 2026 press conference

By Alan Richter

Under the motto “Swiss Made,” Fritz Studer AG held its annual press conference on the occasion of the Motion Meeting 2026 in Steffisburg, Switzerland, Feb. 6, and reported that the builder of cylindrical grinding machines strengthened its global market position, expanded its portfolio, further developed its customer care and invested in infrastructure.

By Alan Richter

Under the motto “Swiss Made,” Fritz Studer AG held its annual press conference on the occasion of the Motion Meeting 2026 in Steffisburg, Switzerland, Feb. 6, and reported that the builder of cylindrical grinding machines strengthened its global market position, expanded its portfolio, further developed its customer care and invested in infrastructure.

“The year 2025 was marked by challenging markets and geopolitical uncertainties. Nevertheless, we exceeded our expectations and emerged from this phase stronger than ever,” said CEO Sandro Bottazzo.

He added that last year’s sales were strong in North America despite customs challenges, and the result in Asia was also positive and higher than the previous year’s level, especially in China. The company’s North American market share is at its highest level in the last decade, and Studer started this year with one of the largest backlogs in its history. Nonetheless, sales in Germany, Italy and Switzerland fell short of expectations.

While automotive, machine tools and precision engineering are large segments for Studer, the company reported the aerospace industry closed as the largest single segment for the first time, accounting for almost a third of all orders.

“Our broad portfolio remains a pillar of success and covers a wide range of universal cylindrical grinding applications,” Bottazzo said.

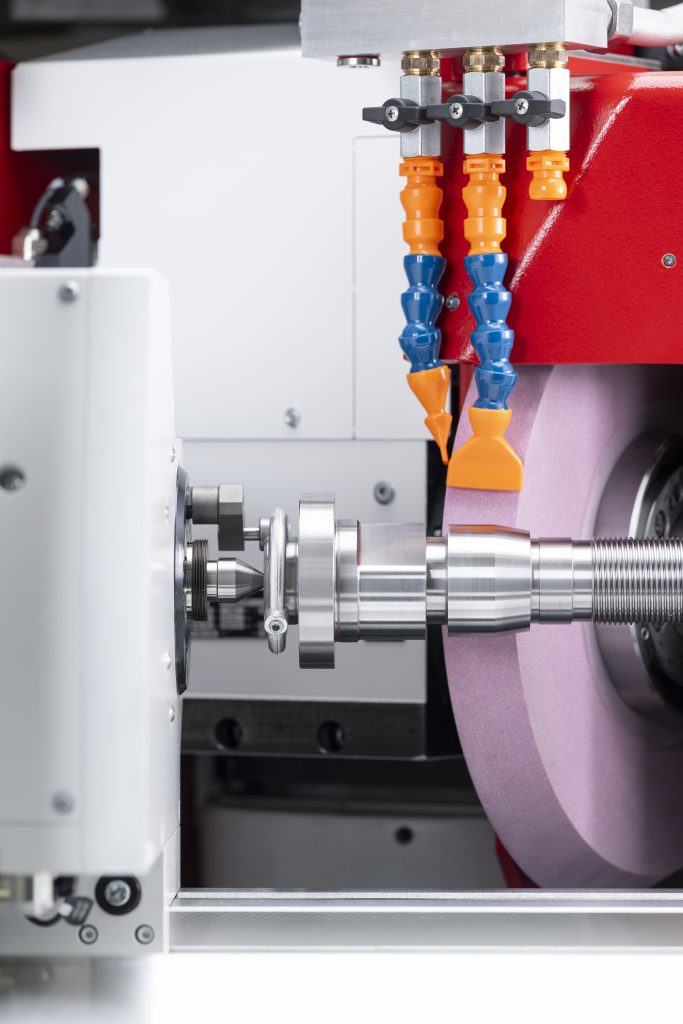

CTO Daniel Huber noted that the main development project last year was the S23 grinder. “One highlight was the world premiere of the S23 universal cylindrical grinding machine with a compact design for precise grinding results.”

The grinder features the C.O.R.E. (Customer-Oriented REvolution) hardware and software architecture, an automatic B-axis with 1° Hirth coupling for up to three grinding tools, frequency-controlled motor spindles or belt drives, and a machine base made of Granitan.

“The C.O.R.E. release 5.0 enables access to Transaction Network’s manufacturer-independent customer portal directly from the machine operating panel and visualizes live status updates of the machine park, among other things,” Huber said.

This year marks the 50th year that Studer has made machine bases with the mineral casting mixture Granitan, which reportedly provides a damping behaviour that is about 15 times better than that of gray cast iron. Compared to gray cast iron, Granitan can absorb twice as much heat energy before the temperature changes by 1° C, according to the company. Heat is also transferred up to 13 times more slowly in the machine bases. At the same time, it has a similar expansion behaviour to steel or iron, which means that no stresses occur at the coupling points to metal machine parts.

Parallel to product development, COO Stephan Stoll said Studer consistently drove forward the transformation of its operational processes. “In 2025, we took our production and logistics processes to a new level,” he said.

This included the creation of a “state-of-the-art” small parts warehouse. The automated system with 32 autonomous robots and 16,000 containers offers space for tens of thousands of parts and significantly increases efficiency for both machine and spare parts logistics, Studer reports.

The machine builder expects solid sales growth in North America and Asia in 2026 after recording a significant increase in the number of machines sold in the third and especially in the fourth quarter of 2025, Bottazzo said.

“Demand for high-quality grinding machines will continue to recover, and the response to our new S23 has been very good. The first machines have already been successfully sold and delivered.”

Motion Meeting 2026 concluded with a “surprise night.” After arriving at the mountain village of Mürren, participants travelled by cable car to the Piz Gloria restaurant at the top of Schilthorn, a mountain summit 2,970 m (9,744') above sea level. One of its claims to fame is that the 360°-resolving restaurant was the “allergy clinic” film location for the 1969 James Bond movie “On Her Majesty’s Secret Service.”