Tool manufacturers utilize automation breakthroughs

Tool manufacturers utilize automation breakthroughs

Industrial automation is changing the way cutting tool manufacturers operate. Machines have taken on the heavy lifting at each stage of production, letting workers get on with less repetitive tasks.

By Duncan Thompson, ANCA Product Manager

Industrial automation is changing the way cutting tool manufacturers operate. Machines have taken on the heavy lifting at each stage of production letting workers get on with less repetitive tasks. And while automation may sound costly and complex to implement, it's not reserved just for big business. There are dozens of ways a small cutting tool manufacturer can embrace automation for a more efficient and more innovative factory.

What are the benefits of industrial automation?

- Cost reduction, through labor costs or machine uptime. The drive for automation is being driven by availability of skilled labor, and machines can fill those gaps.

- Automation is an important step to help people meet regulatory obligations with relation to the limits of weekly work hours without compromising machine utilization.

- Reduced material handling makes running smaller batches much more cost effective.

- Streamlining of existing processes and systems across the business.

- Eliminating mistakes in material management.

- Automating in-process measurement raises the quality of tool production and can nearly eliminate waste, meaning more profit.

Don't invent It's true that bigger companies have more buying power. When it comes to industrial automation, they have plenty of scope to ask for tailored developments to suit very specific needs, or to make these adjustments in house. But as new technology and solutions are developed in response to these requests, the industry as a whole will benefit.

It's true that bigger companies have more buying power. When it comes to industrial automation, they have plenty of scope to ask for tailored developments to suit very specific needs, or to make these adjustments in house. But as new technology and solutions are developed in response to these requests, the industry as a whole will benefit.

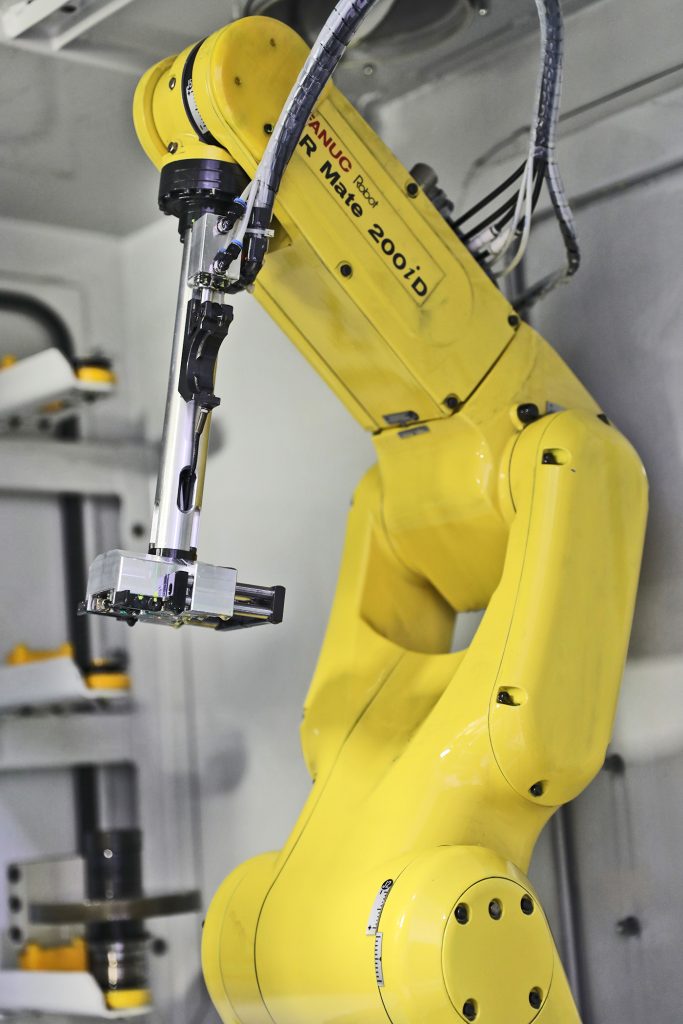

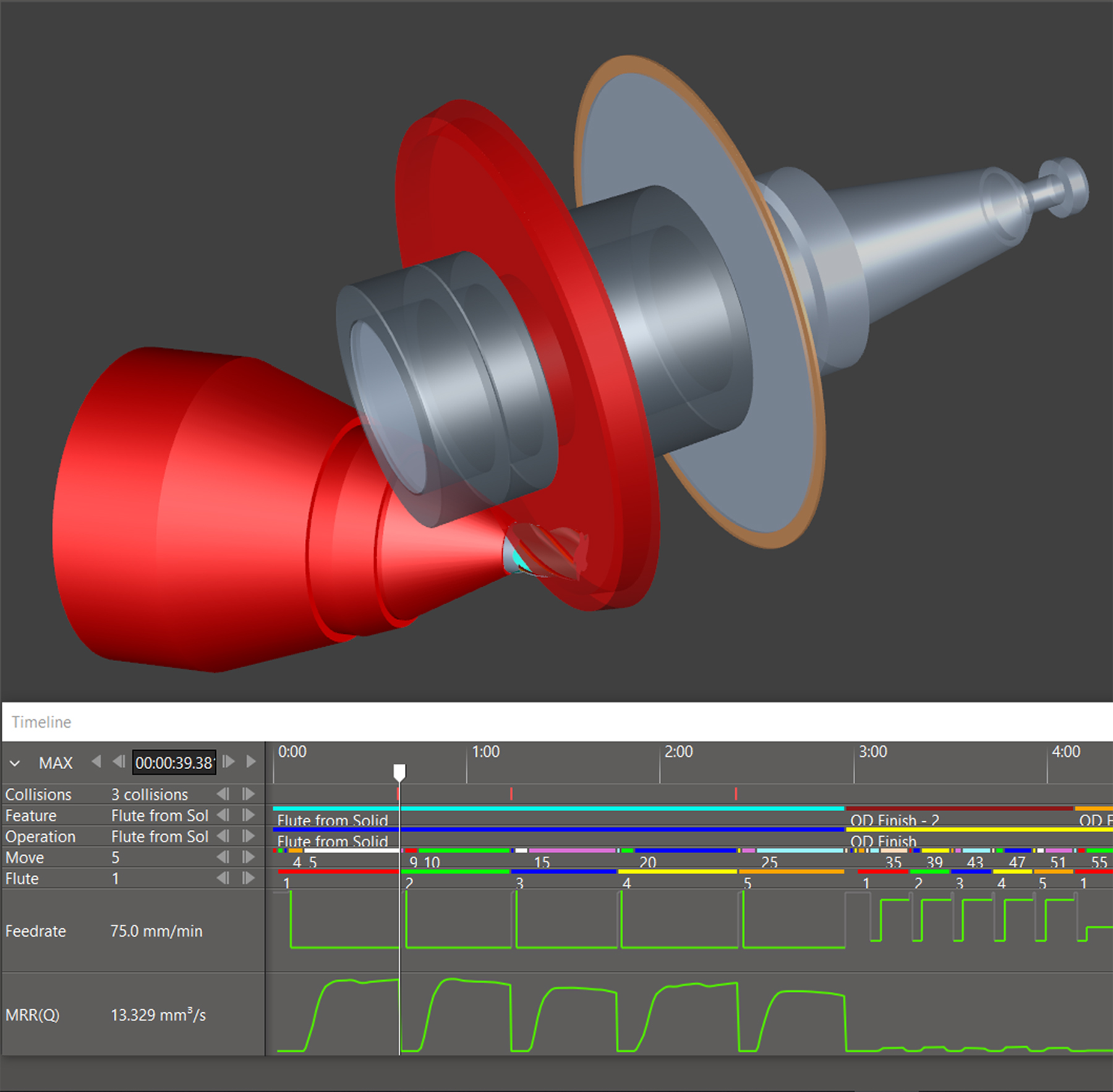

Just because a technology is off the shelf, doesn't mean it is 'standard'. In fact, our industry is constantly evolving as new solutions are found and applied. While their technology development may have been developed at the request of a large customer, as soon as it's scalable it can be rolled out to suit most businesses. At ANCA this includes many of our innovations, including 3D simulation software, our in-process measurement system Laser Plus, and RoboTeach, which makes robotic loaders accessible and easy to program.

The addition of laser etching on a Robot loader is another example that has increased the functionality of the grinding-machine/" data-glossary-id="141847" data-glossary-teaser="Powers a grinding wheel or other abrasive tool for the purpose of removing metal and finishing workpieces to close tolerances. Provides smooth, square, parallel and accurate workpi…" title="Powers a grinding wheel or other abrasive tool for the purpose of removing metal and finishing workpieces to close tolerances. Provides smooth, square, parallel and accurate workpi…" aria-label="Glossary: grinding machine">grinding machine by including what would otherwise have been additional downstream steps in the process of making tools.

As a small tool manufacturer, vendors recognize that your priority is maximizing your factory's efficiency – machine uptime versus setup time. They know that you need software and accessories that will help you keep things ticking over without wasting time and money reloading materials.

Where to start?

Chances are there will be no obvious trigger when it comes to adopting industrial automation. Many smaller businesses won't have planned to develop the level of automation they have. Some may have started only after an increase in labor and setup costs forced them to look for ways to run more smartly. But that is ok, you can build your automation solution piece by piece – as long as you have an agreed vision.

It may be as simple as being observant and seeing which steps in your production process have the greatest cost. Unlike other efficiency drives there is no harm in approaching this piecemeal. Start by attacking the area of your business that will provide you with greatest value. For instance

It may be as simple as being observant and seeing which steps in your production process have the greatest cost. Unlike other efficiency drives there is no harm in approaching this piecemeal. Start by attacking the area of your business that will provide you with greatest value. For instance

At the smaller end of the tool cutting market there's a good chance you're producing small batch lots and changing geometry multiple times a day, rather than leaving the machine running constantly making the same tool all day.

In this world, innovation is often a secondary need to maximizing day-to-day productivity. For instance, look for solutions that allow the operator to step away from the machine and carry out other tasks, rather than being there all day. Automating geometry changes and your existing manual material management processes can make a real change to how much they are able to do elsewhere and help you maximize machine uptime vs. setup time. Time is, after all, money.

You may not have the business budgets to request tailored solutions, but out-of-the-box solutions are available that can be used to manage inventory, integrate with your ERP to manage job order, and even pack ready for dispatch. Many will work effectively with your existing processes, even if you have never automated them before.

Industrial automation can keep your focus on people

A small cutting tool factory relies on every working part being up to scratch – and that includes your people. Automation removes the risk of human error creating a safer working environment that's less likely to be disrupted. Furthermore, changing government legislation is limiting how many hours employees can work. Automation is the obvious solution to maximize machine up time when people are not present.

Applying industrial automation solutions that connect you more to your customers will allow you to see in real time what they're low on, what's in high demand, or what's coming up in your production that will suit their requirements. This allows you to explore other areas of production and manufacture tools knowing with confidence what your customers want.

Existing solutions

Automation can take the pain out of being a small tool shop. Your new factory of the future will be able to produce multiple kinds of tools without getting bogged down in manual operations.

We can all benefit from streamlining systems and processes. Focus on your speciality and leverage the tech that's already out there. There are better ways for you to use your time. Grind the wheel, don't reinvent it.