Turn to a fine balance between insert hardness and toughness

Turn to a fine balance between insert hardness and toughness

At first blush, hardness and toughness may seem like interchangeable concepts, but they actually exist at opposite ends of a continuum that defines indexable and solid tool performance, particularly when it comes to carbide inserts. Harder inserts offer greater wear resistance for superior performance and tool life in hot cutting environments, while tough inserts can handle greater impacts and stressors for the highest feed and depth of cut. For any given application, there is an optimal balance of hardness and toughness – and toolmakers have worked diligently to establish metallurgic principles to offer a range of tools that can meet the diverse needs of manufacturers.

Article from Seco Tools LLC

At first blush, hardness and toughness may seem like interchangeable concepts, but they actually exist at opposite ends of a continuum that defines indexable and solid tool performance, particularly when it comes to carbide inserts. Harder inserts offer greater wear resistance for superior performance and tool life in hot cutting environments, while tough inserts can handle greater impacts and stressors for the highest feed and depth of cut. For any given application, there is an optimal balance of hardness and toughness – and toolmakers have worked diligently to establish metallurgic principles to offer a range of tools that can meet the diverse needs of manufacturers.

Hardness represents wear resistance, which translates to a tool's ability to withstand byproduct heat during metal cutting. The Rockwell A scale measures the hardness of tungsten carbide, although some specifications translate HRA values to the more-familiar HRC scale used to measure steels. The temperature resistance that correlates with hardness plays a huge role in cutting tool behavior and selection.

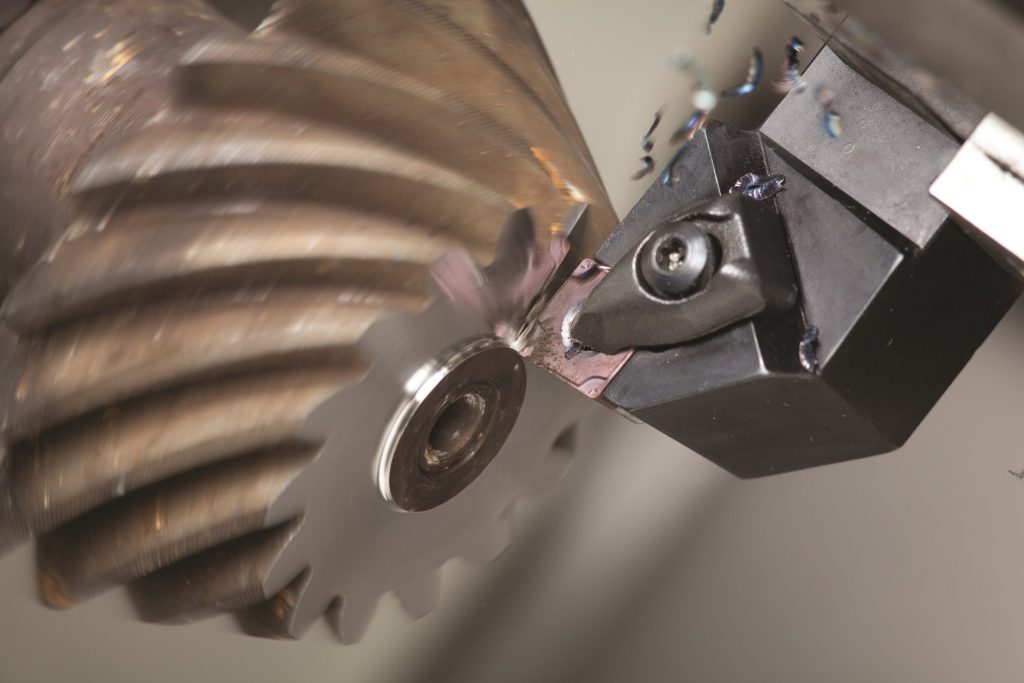

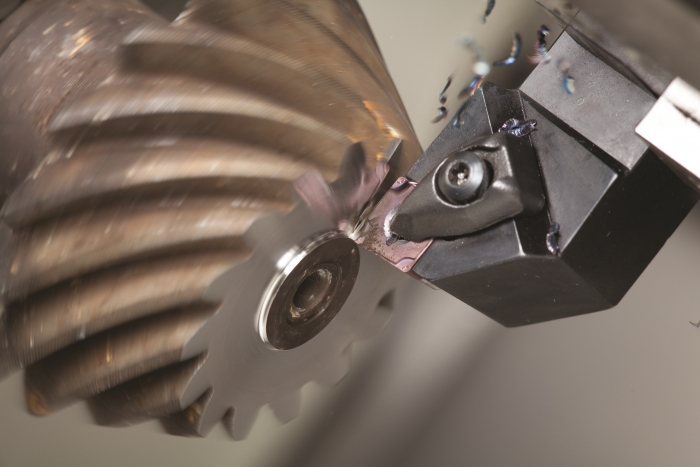

In the cutting zone, temperatures can rise above 1,400° F. Hard carbide can withstand and dissipate those temperature levels and, therefore, handle the high heat generated in continuous cutting. High hardness levels can make metal brittle, however, which explains why heat-resistant carbide tools tend to chip in situations that produce large amounts of pressure or vibration.

At the other end of the continuum, toughness represents pressure and impact resistance, which correlate with a tool's ability to withstand high feed rates, heavy depths of cut and the impact associated with interrupted cuts. In exchange for durability, however, tough carbide becomes vulnerable to heat, which makes it less than ideal for high-speed, continuous cutting.

Both these attributes tie directly to the elements that make up carbide: tungsten, carbon and cobalt. Tungsten promotes both hardness and toughness while carbon boosts hardness, and the combination of the two elements yields tungsten carbide molecules. Cobalt, meanwhile, has a lower melting point than tungsten and carbon, contributes to toughness and intensifies the performance characteristics of other elements. In tungsten carbide, cobalt serves as a binder, essentially a glue that holds carbide grains together.

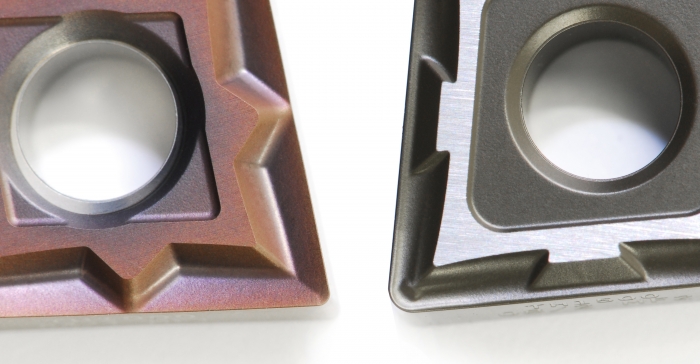

Grain size can also determine hardness and toughness – hard carbide grades have smaller grains and tough grades have larger ones. Hard grades need less cobalt binder to hold their grains together, which promotes better heat resistance for longer tool life during continuous cutting. Tough grades include more cobalt binder, which gives the carbide grains better adherence to help the tool handle pressure and vibration but with less heat resistance. Midway between hard and tough, general-purpose carbide grades produce cutting tools that can handle slightly interrupted cuts and offer considerable but not extreme wear resistance.

The current state of metallurgy means that no magic alloy offers both extreme hardness and extreme toughness. Today's cutting tool performance improvements often focus on two areas: the addition of super alloys or other enhanced materials to the cobalt binder itself, and the production of enhanced coatings to increase wear resistance.

Material development also sparks cutting tool innovation. Today's workpieces can feature powder metals, carbon fiber-reinforced plastics and stacked and layered materials with fiber directionality that varies from batch to batch. When industries create new materials to cut down on surface-against-surface wear in medical implants or produce lightweight options for aerospace manufacturing, for instance, cutting tool manufacturers must respond with products that can optimize the machining of these new materials. In some cases, existing tools prove they can effectively cut these materials. In others, the development of new tool technology is required.

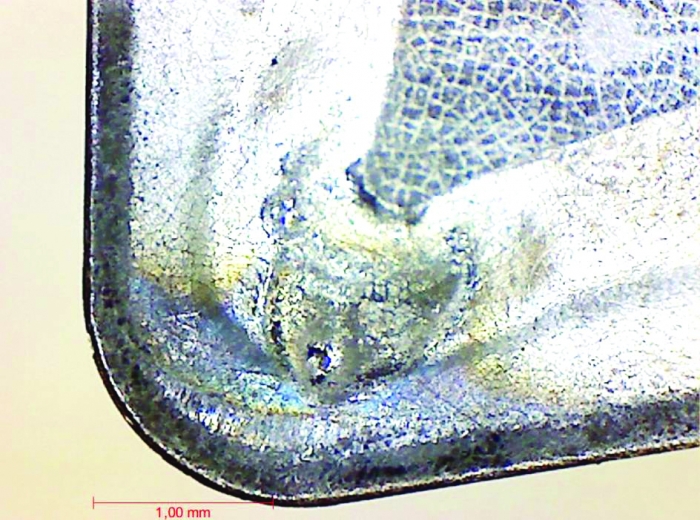

Shops that experiment with cutting tools only to experience shorter-than-expected tool life can use tool behavior to help them find and correct the causes of failure. For example, inserts that develop large craters in continuous cutting applications show their lack of wear resistance and indicate the need for a harder tool.

Conversely, if a hard grade fractures in a continuous cut, wear analysis quickly shows the need for a tougher tool instead. In these instances of tool fracture or breakage, shops should also evaluate the condition of the toolholder along with the stability of the machine tool itself and the part setup.

With the increased focus on hard part turning, shops also need to decide whether to machine before or after a material reaches its hardened state – and make cutting tool selections that match the hardness of their materials. In a "green" state, many materials test at half the hardness they demonstrate after hardening, with an obvious effect on tool selection, life and behavior. Additionally, case-hardened and through-hardened materials present two very different hardness scenarios. Case hardening creates a hard surface with potentially softer material underneath it, while through hardening produces a uniformly hardened workpiece. In these cases, DOC plays a vital role in tool selection because it determines whether the task requires an insert that can cut hard or less-hard material.

Cutting tool manufacturers strive to support their customers' success with innovative tools and thorough support for informed tool selection. Seco Tools continues to develop grades, geometries and coatings that handle new materials with excellent results, and to add new performance options for existing materials. Our Tec Team ([email protected]) always stands ready to guide customers toward optimal selections for individual and unique cutting tasks. Shops that want to assure they make the right choices between hardness and toughness can benefit from our expertise to optimize the productivity of their cutting applications.