ZYGO displays automated optical measurement at IMTS

ZYGO displays automated optical measurement at IMTS

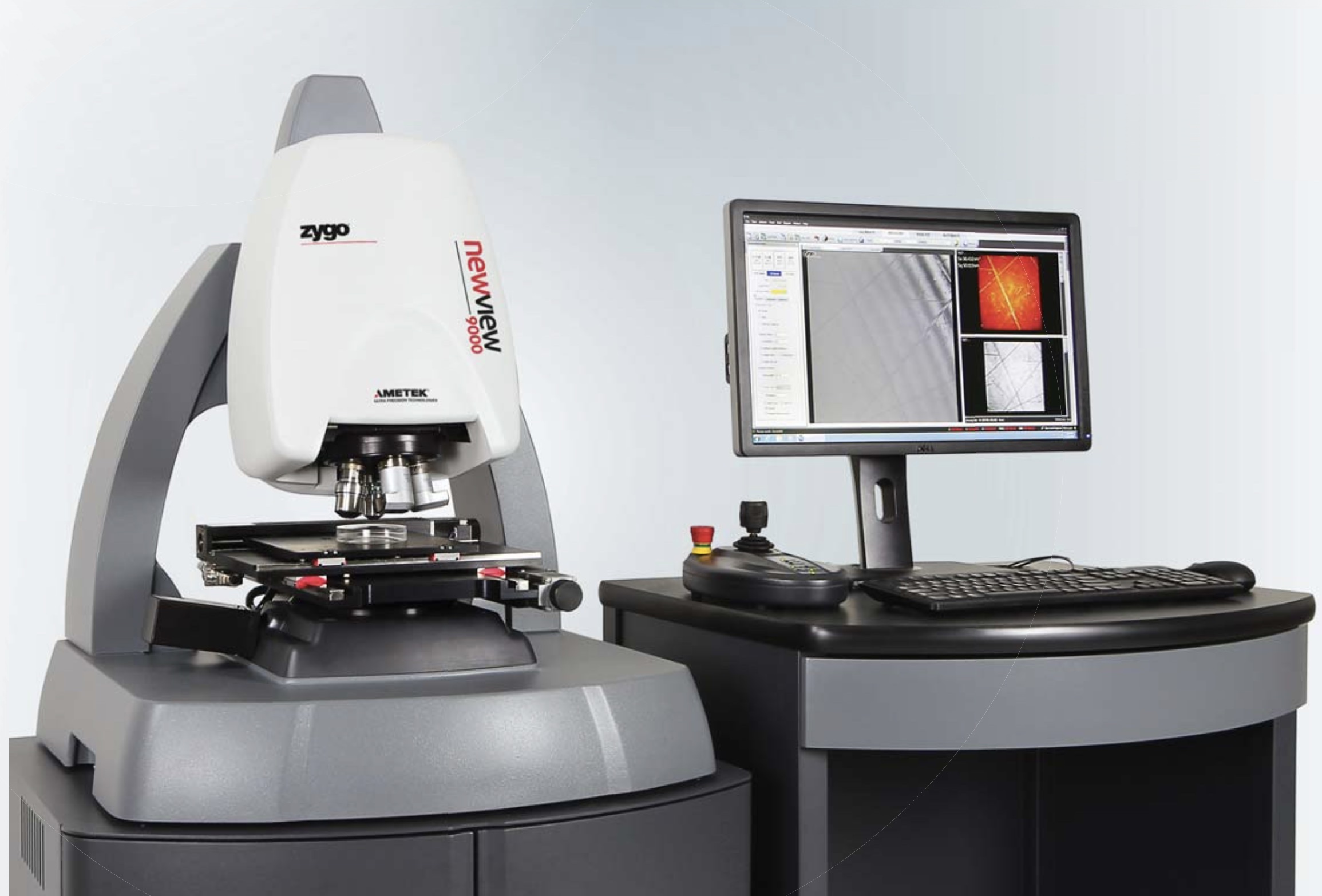

Zygo Corp. is showcasing part of its 3D optical profiler range — the ZeGage Pro HR, the NewView 9000, and the NewView NX (fitted with a robotic arm to demonstrate how sample measurements can be automated) — and the VerifireTM 3.39 IR laser interferometer.

Zygo Corporation, a business unit of AMETEK Inc., is showcasing part of its 3D optical profiler range — the ZeGage Pro HR, the NewView 9000, and the NewView NX (fitted with a robotic arm to demonstrate how sample measurements can be automated) — and the VerifireTM 3.39 IR laser interferometer.

According to the company, Zygo's 3D optical metrology tools are crucial in advanced manufacturing settings due to their ability to provide precise and accurate surface measurements and quality control, essential for the production of high-performance components in a range of high-tech industries. These tools enable manufacturers to achieve tight tolerances and ultimately ensure product reliability, the IMTS show providing an ideal platform for Zygo to display its innovative approach to the production of cutting-edge metrology solutions, and giving attendees the opportunity to discuss partnering to achieve manufacturing goals.

Michael Schmidt, senior product development Manager at Zygo says, "At the IMTS event, we will be showing our Nexview NX2 optical profiler with a robotic arm facilitating automated sample measurements. Automating sample measurements enhances precision, consistency, and efficiency in data collection compared to manual sample changes. It minimizes human error, ensures repeatable positioning, and allows for continuous operation, significantly speeding up the measurement process. It also reduces the risk of sample contamination and mechanical damage and frees up skilled personnel for more complex tasks. Automated sample measurement is crucial in high-precision industries such as semiconductor manufacturing, biomedical research, and materials science where accuracy, consistency, and efficiency are paramount."

The Nexview NX2 offers fast, precise measurements of surface roughness, topography, and film thickness without the need for sample preparation, and can handle a broad range of surfaces, from super-polished optical surfaces with sub-Angstrom roughness to steep machined angles up to 85 degrees. It can also perform quantitative areal metrology, making it suitable for diverse applications across various industries. At the IMTS event it will be shown alongside the NewView 9000 optical profiler, which incorporates Zygo's proprietary Coherence Scanning Interferometry (CSI) technology, which enables measurements of steep slopes and transparent materials, making it ideal for complex sample analysis in the semiconductor, precision optics, and medical device industry where

meticulous and comprehensive surface analysis and quality control are vital.

Schmidt continues, "Also at the IMTS event, attendees will be able to see the ZeGage Pro HR optical profiler in action. Unlike other optical surface profilers, the ZeGag Pro HR maintains high precision at all of its magnification options, and it is not affected by the environment it operates in. You can take it out of the QA lab, place it directly beside your production equipment, and get precise 3D surface metrology. Built on Zygo's proprietary CSI technology, the ZeGage Pro HR enables precise, reliable, simple, and confident surface metrology efficiently and cost-effectively across a range of industry applications."

In addition to its 3D optical profilers, Zygo will also be showing its Verifire 3.39 Infrared (IR) laser interferometer at the IMTS event. The company has long been recognized as a world leader in interferometeric testing, and has designed and manufactured several specially-equipped interferometer systems ranging from the deep ultraviolet to the far infrared.

Schmidt concludes, "The Verifire 3.39 IR laser interferometer is designed for general IR optical system testing used to evaluate and characterize optical performance. It is crucial for ensuring the performance and reliability of infrared optical components and systems, commonly used in applications like thermal imaging, remote sensing, and infrared spectroscopy. Come along to booth 134470 at the IMTS, and let's discuss how our range of optical metrology solutions can assist in your exacting manufacturing endeavours."