Episode 84: Defining truing parameters

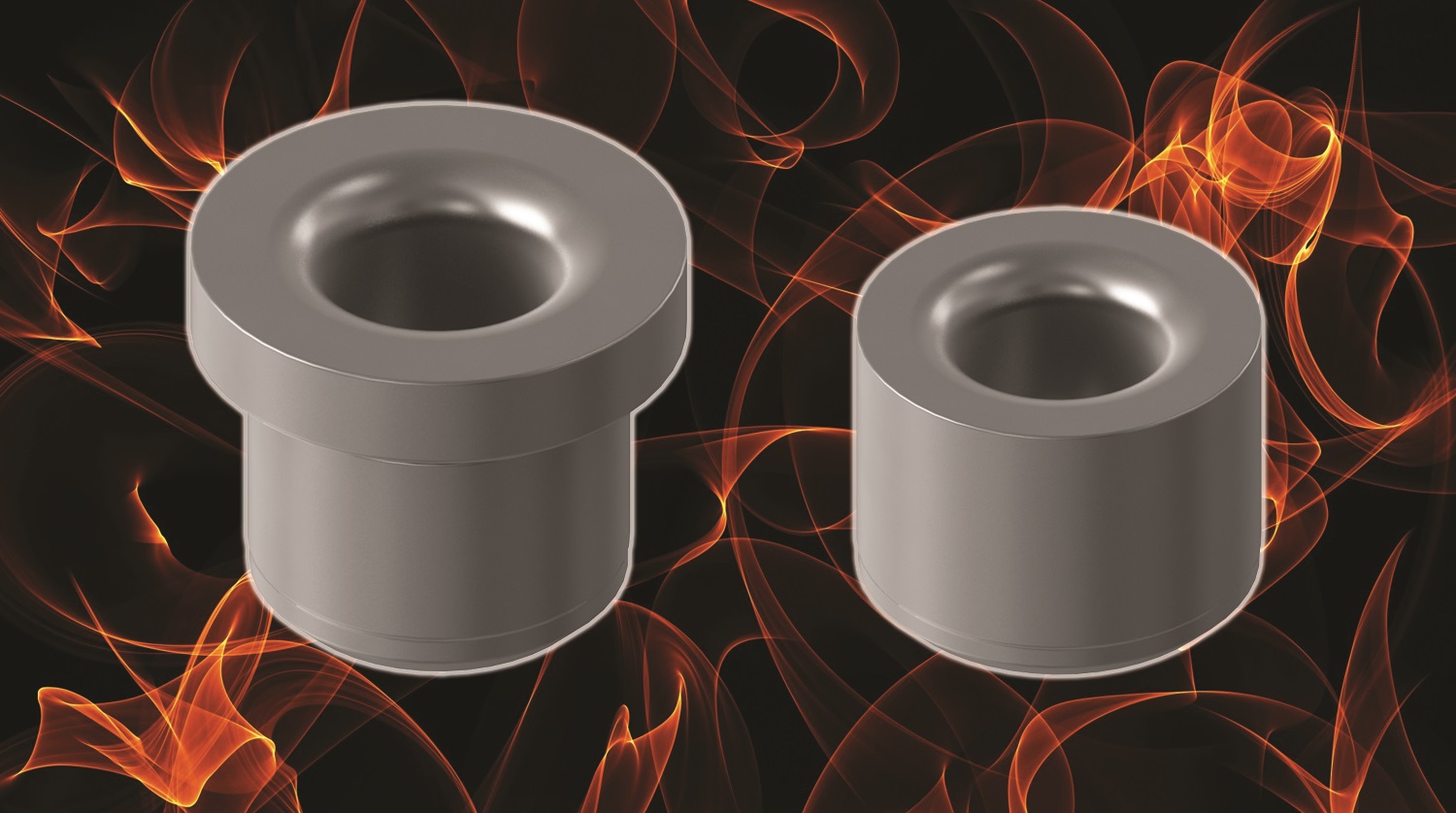

For the 84th episode of the CTE Grinding Doc video series, Dr. Jeffrey Badger offers some preliminary results and observations from his work with Rush Machinery to establish scientific truing parameters.