Gear toothing with Schwanog

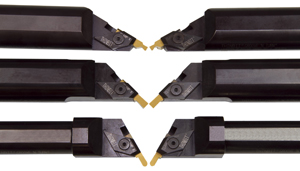

Schwanog's PWP broaching system reportedly can produce internal and external shapes, such as serrations, splines, hexagons and keyways, on CNC lathes with a c-axis. The system includes an insert ground to create the desired shape, a retaining screw and a steel toolholder.

-300x157.jpg)