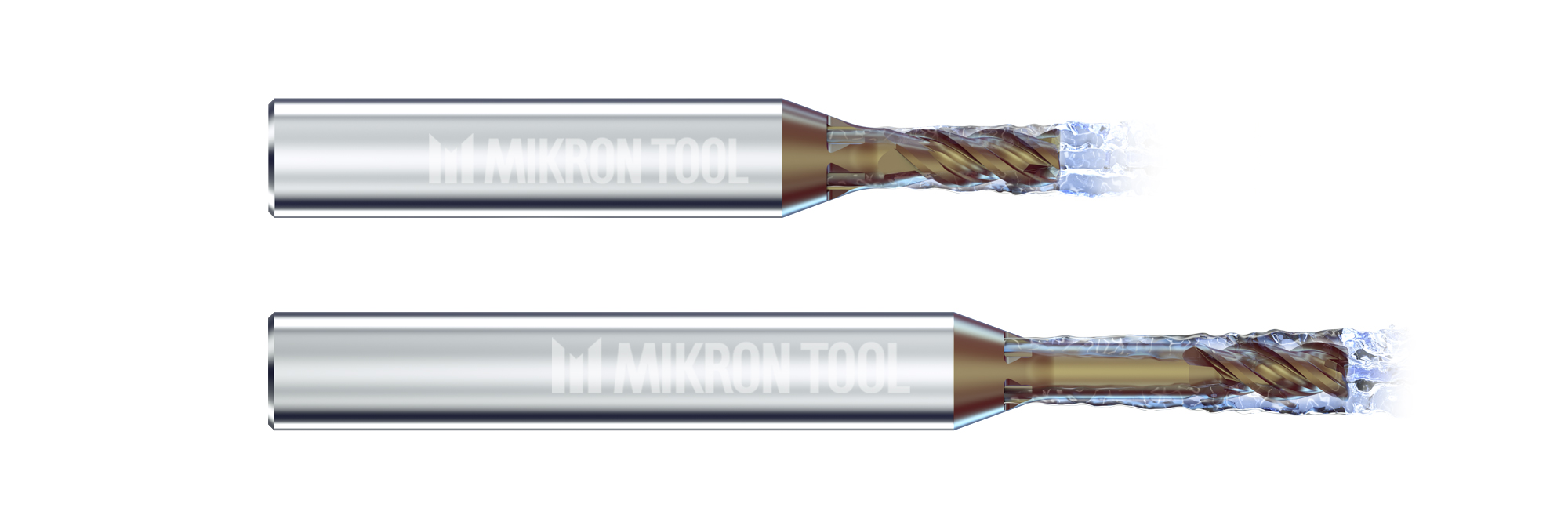

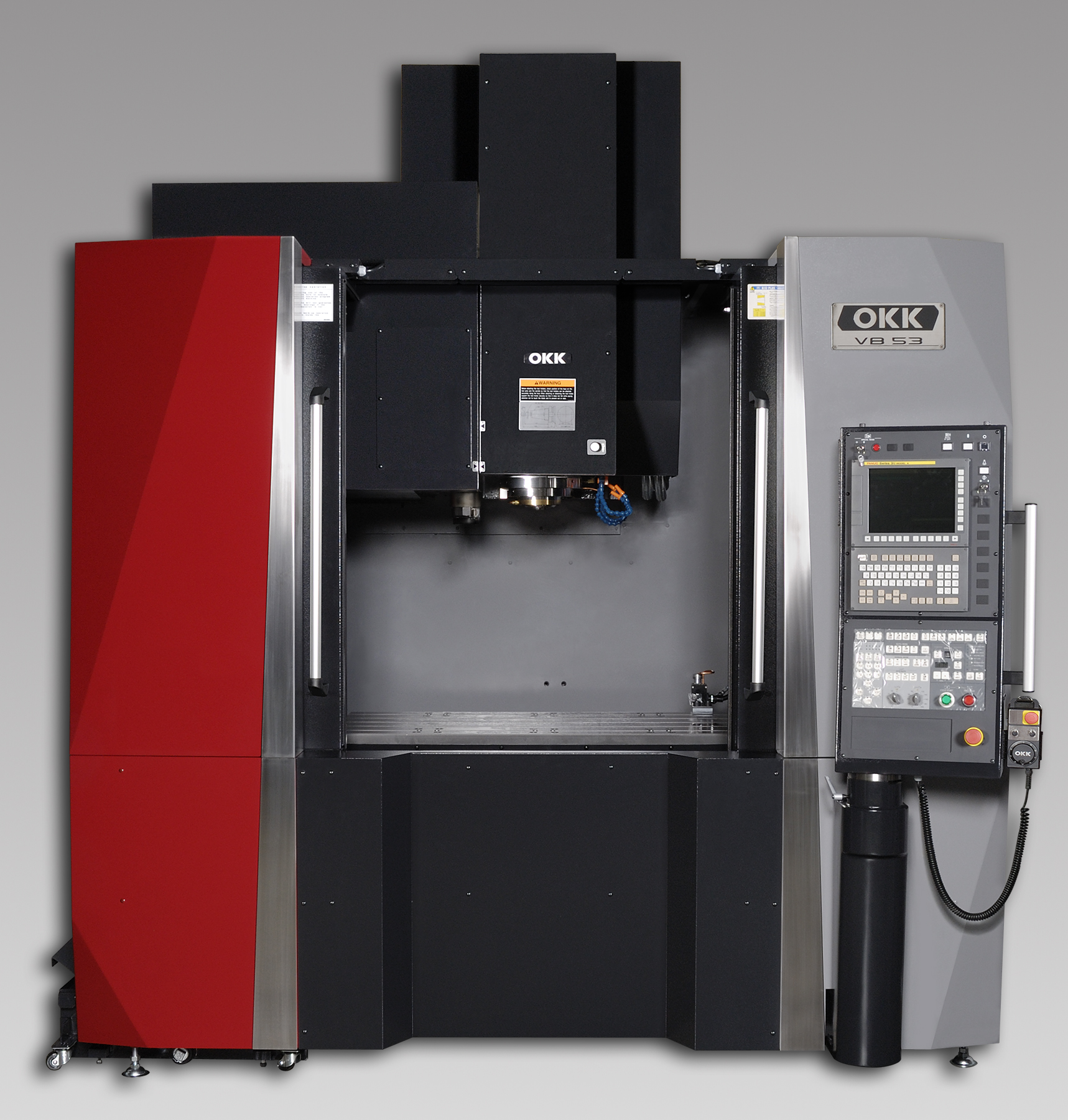

An engineered approach to deep-hole drilling

Books have been written on how to produce deep holes using milling machines or lathes, but trying to drill deep holes with depth-to-diameter ratios greater than 15-1 (D-d) using standard machining centers often leads to frustration, costly scrap and poor use of shop resources.