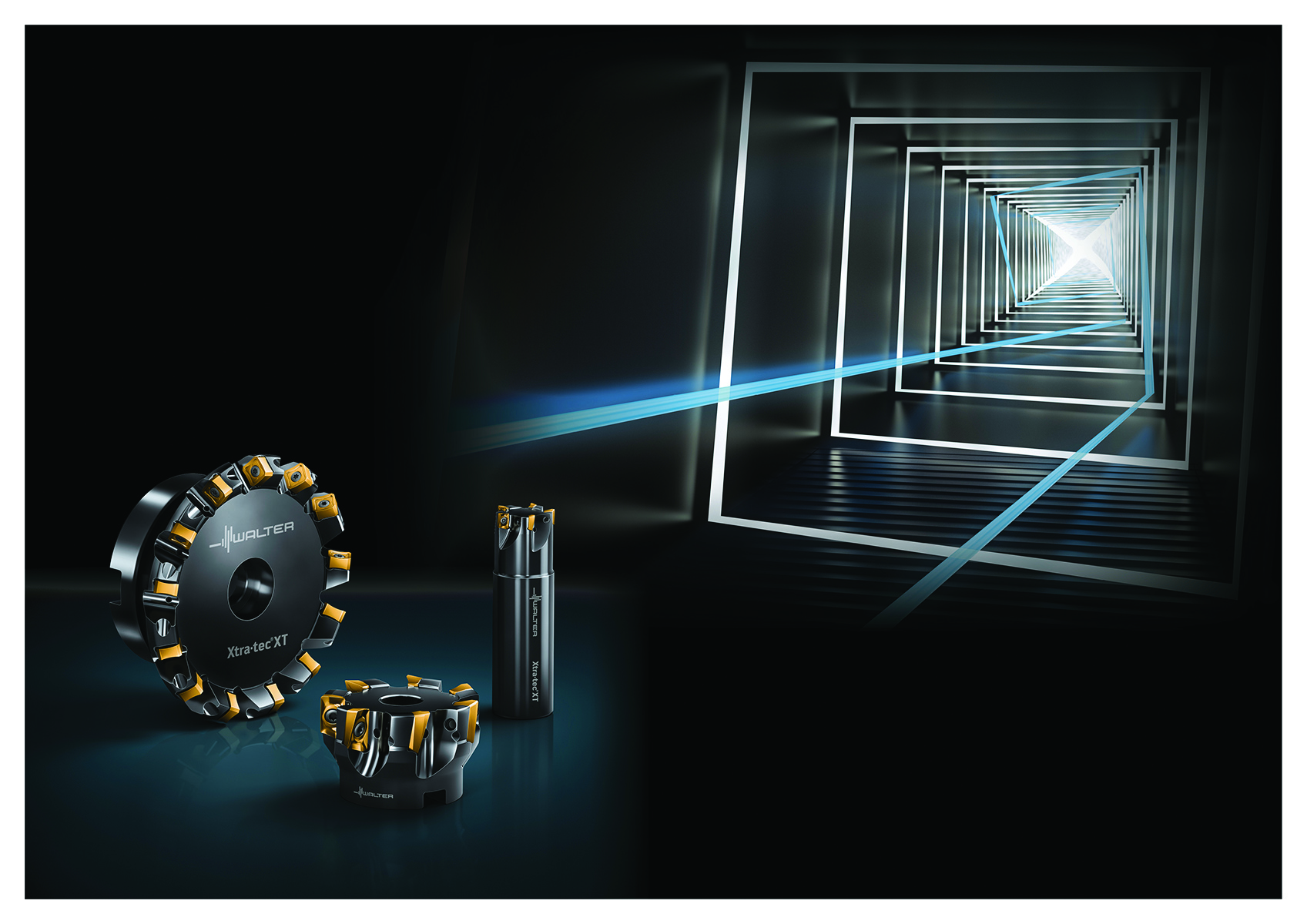

Xtra·tec XT Milling Tools

Walter has introduced its next generation of milling tools: the Xtra·tec XT (Xtended Technology). Designed to achieve increased productivity and process reliability, this new generation of milling cutters is being launched with initial offerings of shoulder milling cutters and a facemilling cutter. The mills cover virtually all requirements in shoulder and slot milling in all common material groups.