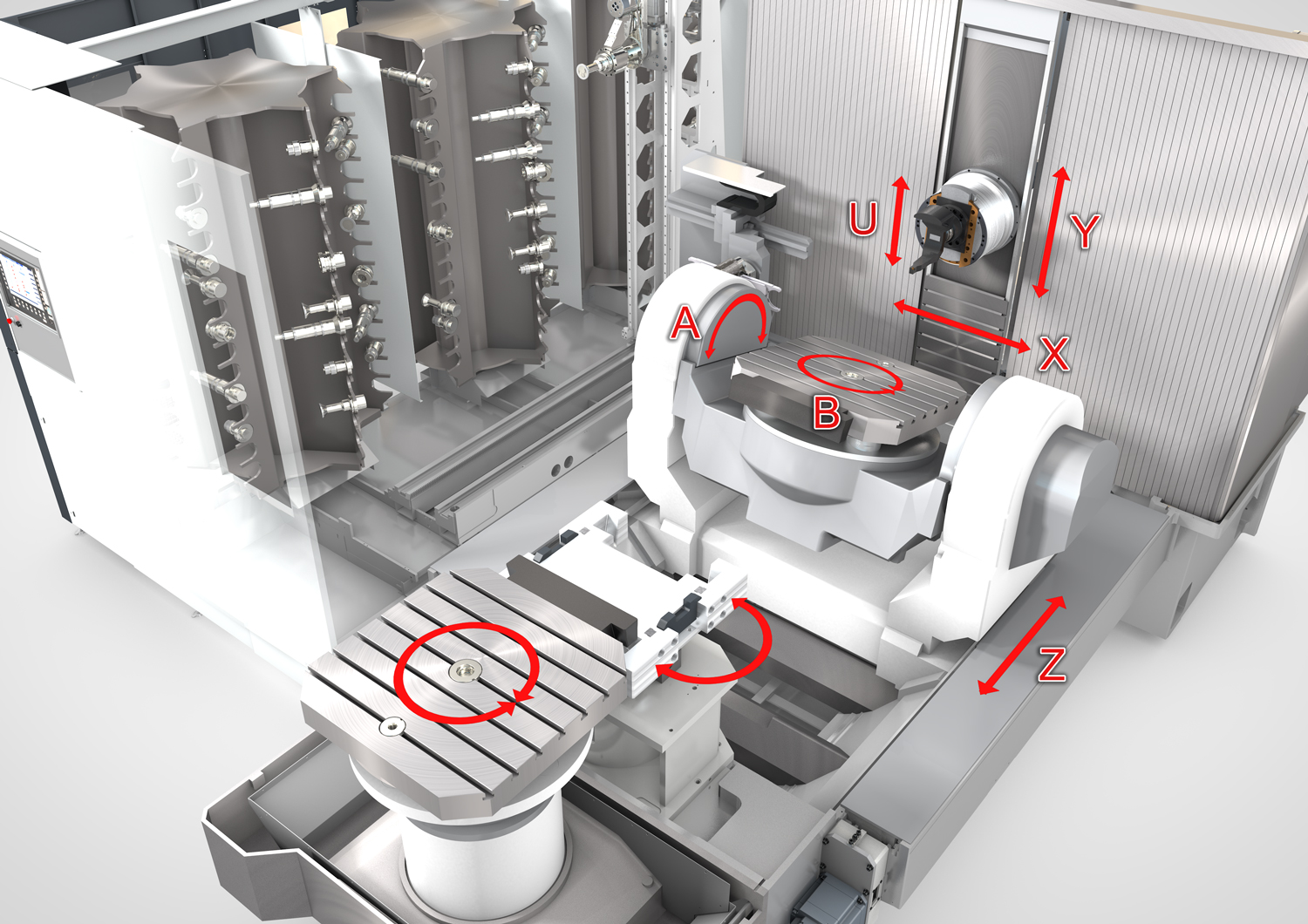

Bumotec s191FTLR 7-Axis Turn/Mill Machine

Starrag has demonstrated over the years that the nonexhaustive list of applications performed on its model Bumotec s191FTLR 7-axis turn/mill machine is an evidence of Starrag's expertise in manufacturing complex parts in a single setup whatever raw materials used. Whether for producing parts in the micro-mechanics, aerospace, medtech or luxury goods sectors, Bumotec machining centers dedicated to small workpieces turn out to be a major asset to achieve your production goals and overcome the current market challenges. In the medical field, requiring high level of precision and repeatability, the company's technology is often used to obtain the cost-effective solution for producing implants combining grinding, milling, turning, drilling and polishing processes without interruption.