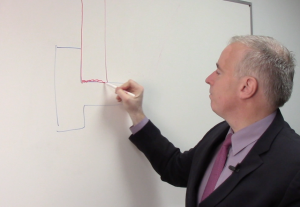

Episode 81: Diagnosing shoulder pain

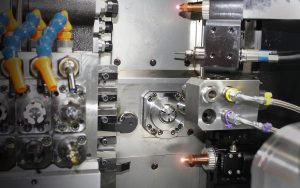

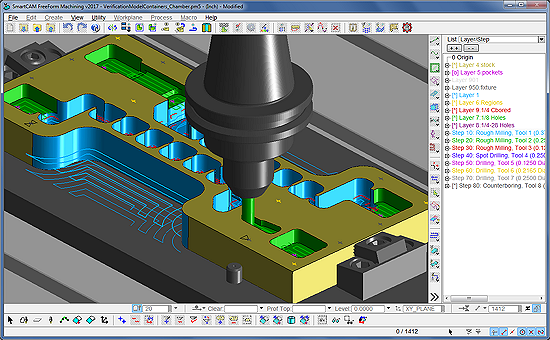

Dr. Jeffrey Badger examines why many shops experience pain when cylindrical grinding a face, or shoulder, in the 81st episode of the Ask the Grinding Doc video series, which is produced in collaboration with Cutting Tool Engineering.