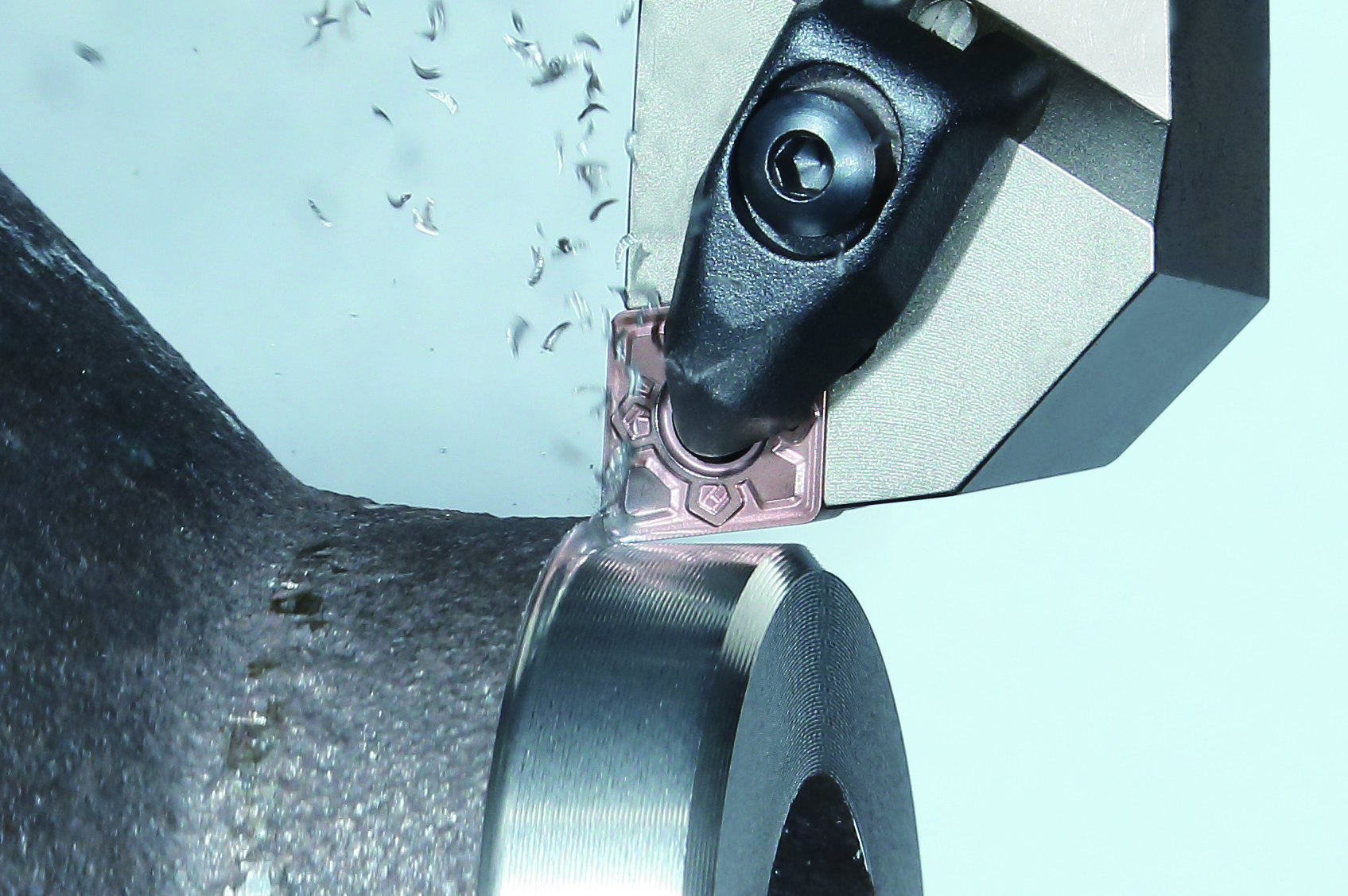

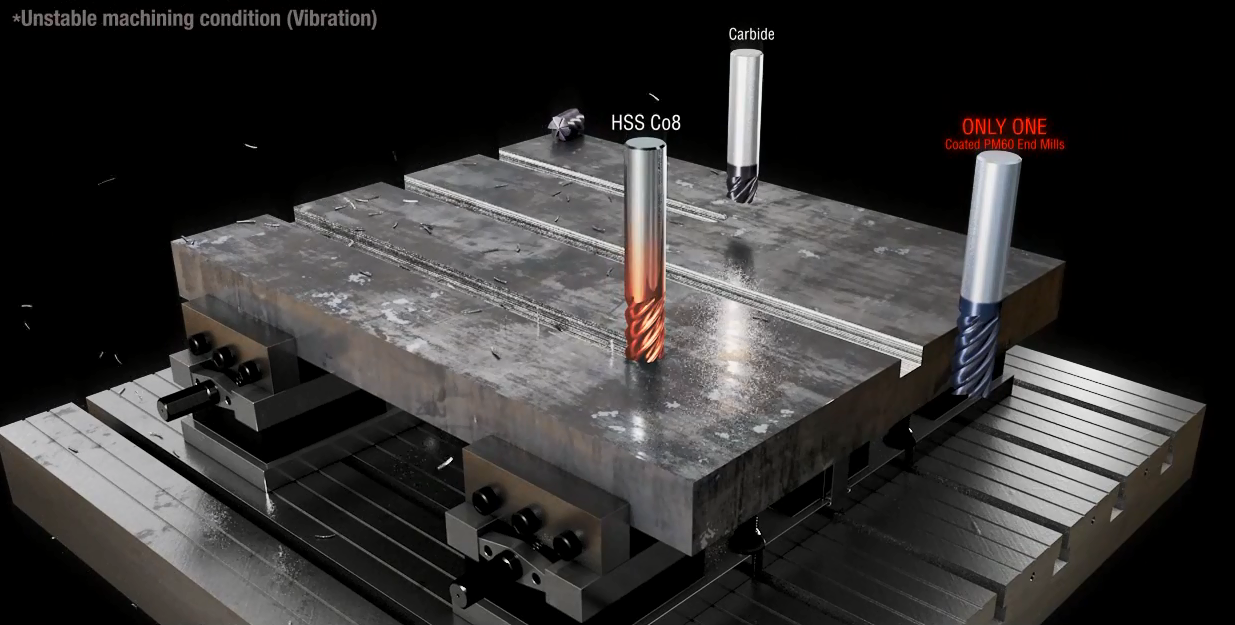

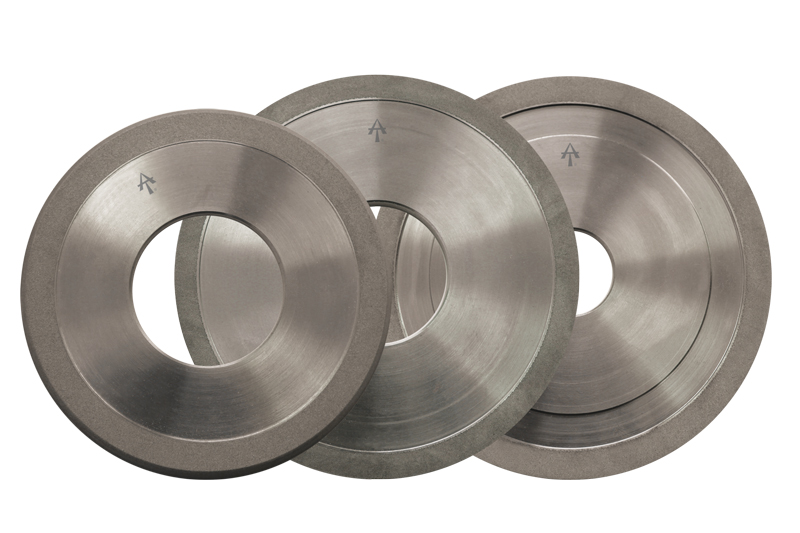

Portfolio of ISO Tools for Milling Operations

MAPAL offers a broad portfolio of ISO tools for milling operations. A new series of cutting materials has been developed especially for the milling of the whole bandwidth of cast iron grades – GJL, GJV and GJS.