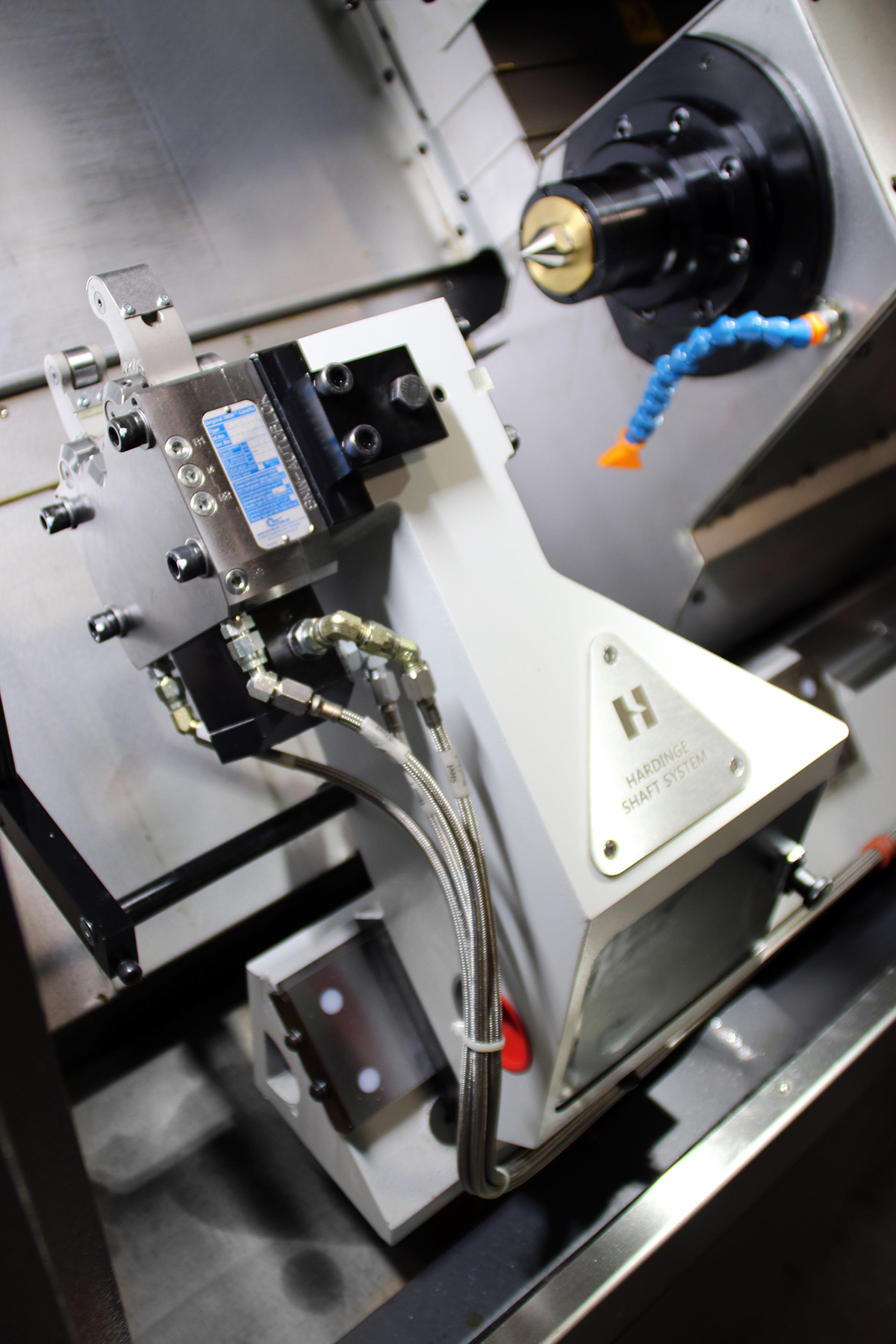

GTI Spindle’s new repair facility fully operational

GTI Spindle Technology Inc., Manchester, N.H., recently opened a state-of-the-art facility in North Carolina that the company said is capable of repairing and rebuilding high-precision spindles, including those made by Makino, Mazak, Kessler, Gamfior, Enshu and OKK.