-01.jpg)

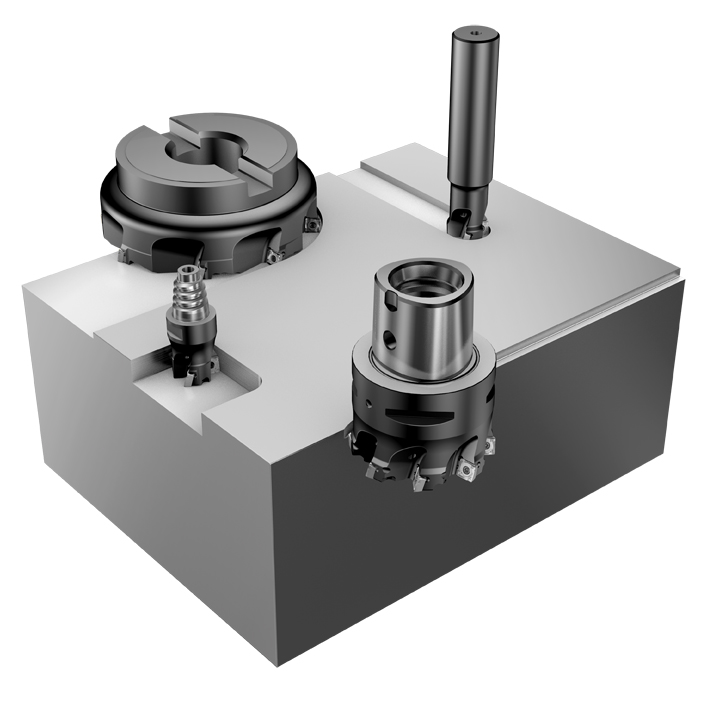

VTM-1200YB Multitasking CNC Turning Center

Okuma's VTM-1200YB multitasking CNC turning center is built to handle heavy-duty turning and cutting of large parts. The massive construction, extreme rigidity and powerful cutting capabilities of this machine make it ideal for machining large diameter workpieces, such as those in the aerospace and energy industries, according to the company.