Scientific Cutting Tools at MT Series East (EASTEC) 2025

Sarah Christopher Falk of Scientific Cutting Tools introduces the company's diverse lineup of precision cutting tools at MT Series East 2025. She highlights their range of solid carbide and carbide-tipped solutions, including indexable tools, specialized engraving tools, and high-performance thread mills.

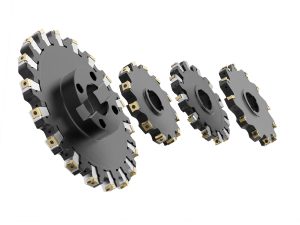

_0-300x169.jpg)