Clean coolant makes for quality cutting

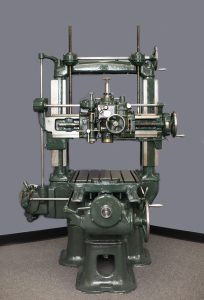

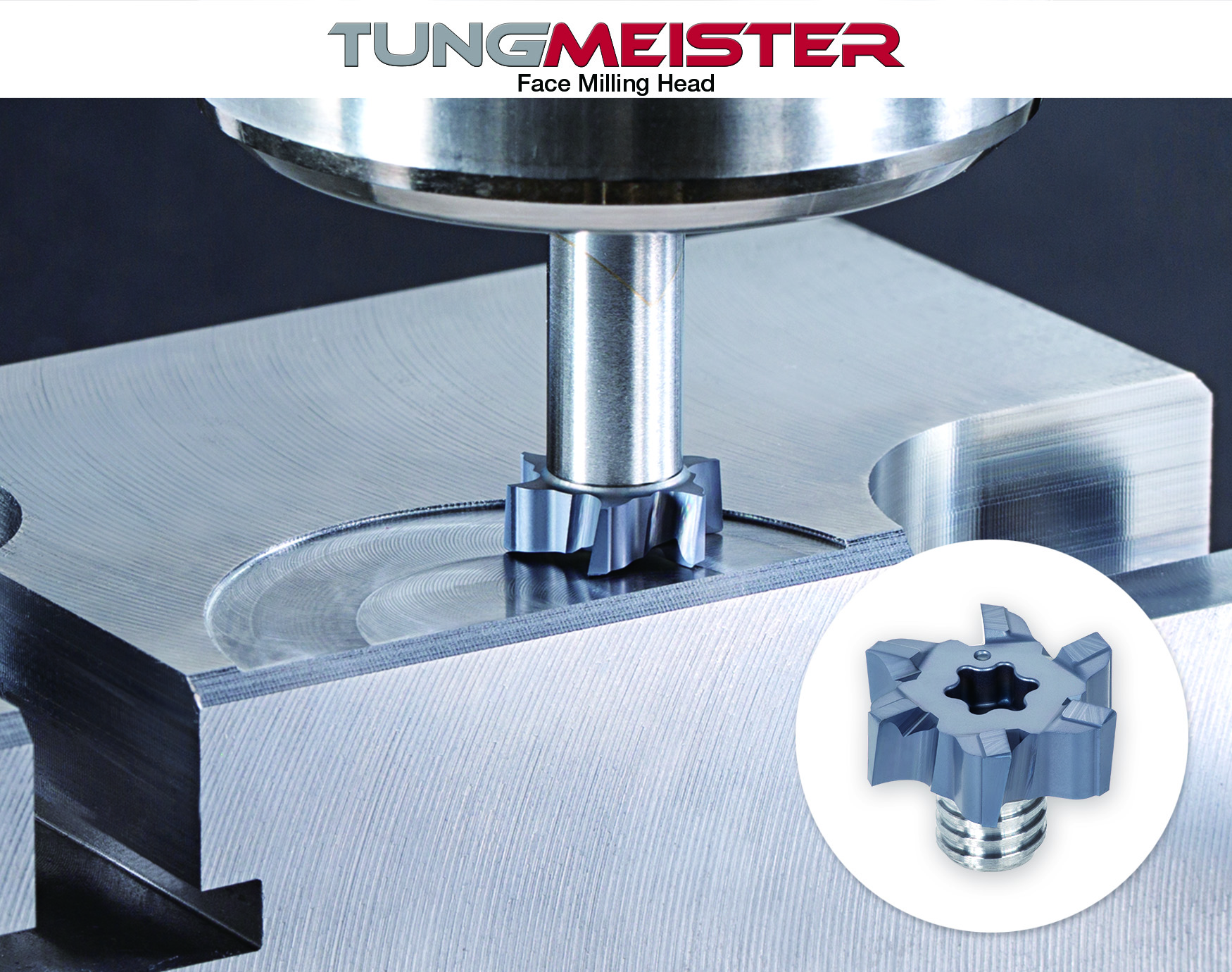

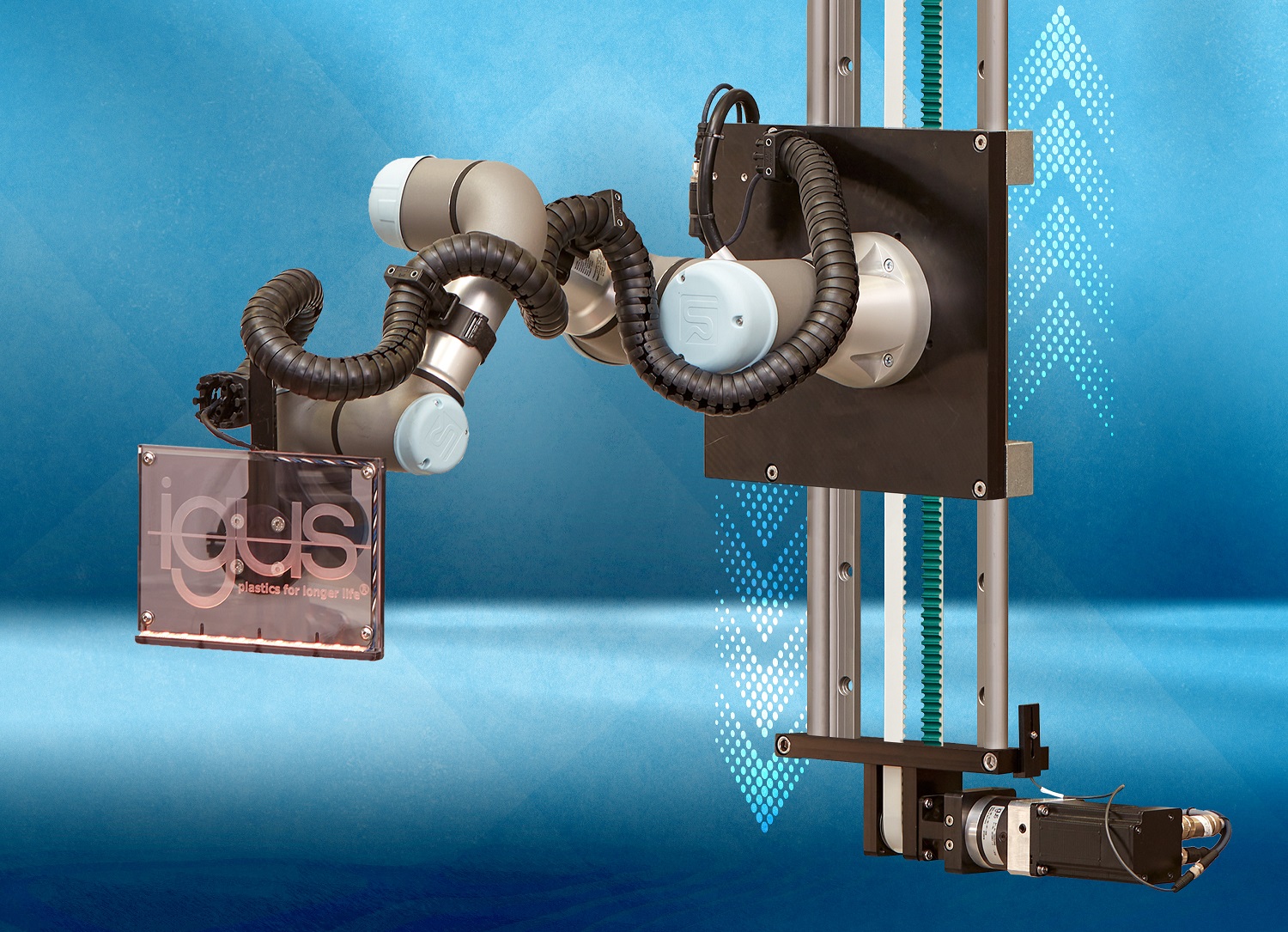

Whether operators use neat oils or water-miscible coolants in wet cutting machine tools or tool grinding machines, the coolants are subject to heavy contamination. VOMAT technology offers a variety of clean coolant technology to solve this problem and produce better cuts.