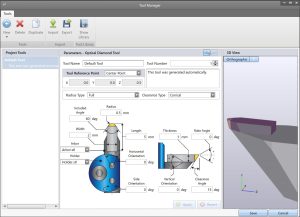

hyperMILL 2019.1 CAD/CAM Software Suite

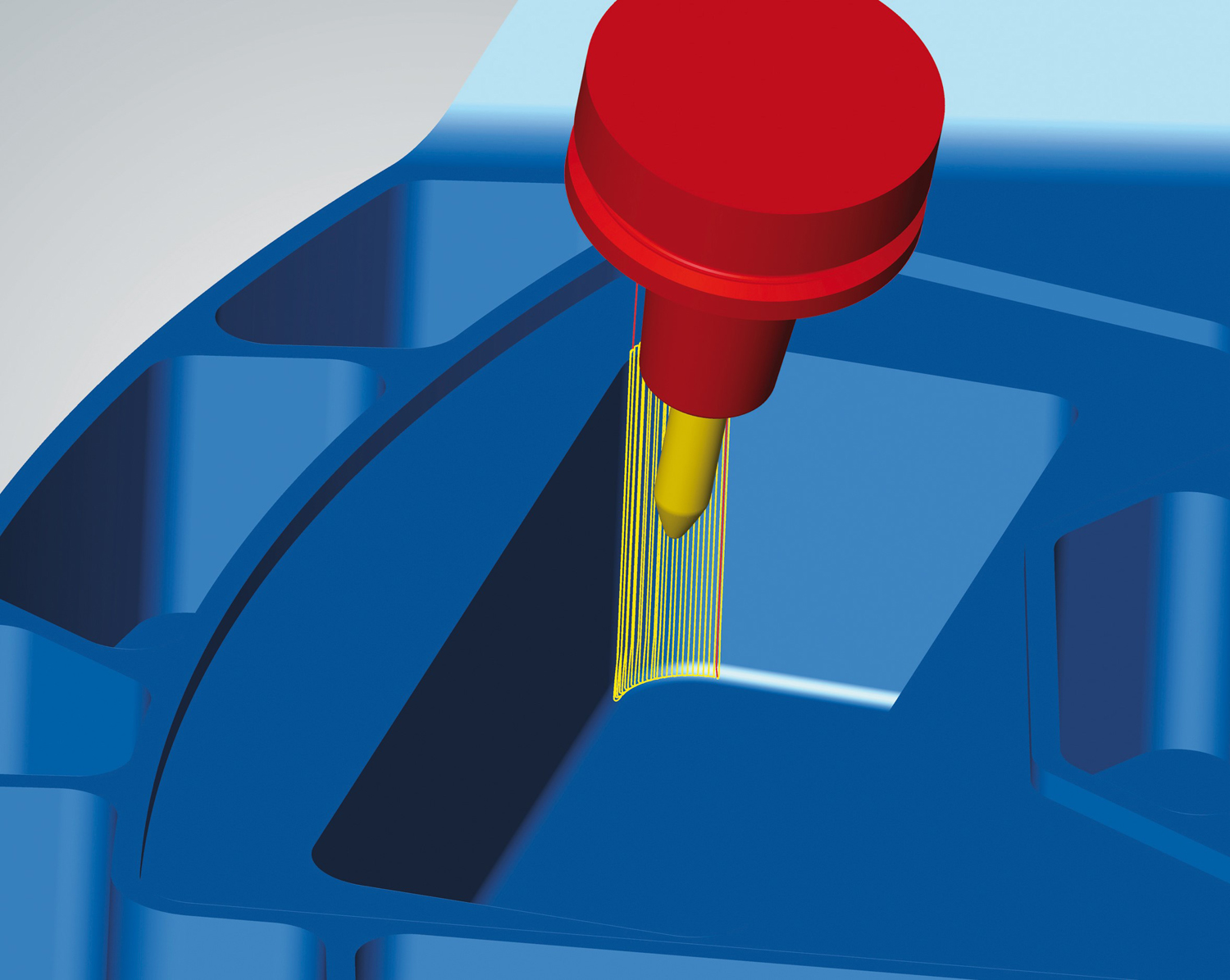

Open Mind Technologies has introduced hyperMILL 2019.1, a new version of its advanced, comprehensive CAD/CAM software suite. hyperMILL 2019.1 has a range of new features and enhancements including an expanded Finishing Module in the hyperMILL MAXX Machining Performance Package, process optimizations such as a new thread milling module, a new function for reducing calculation times, tool database flexibility, and CAD optimization.