Products

•

September 18, 2019

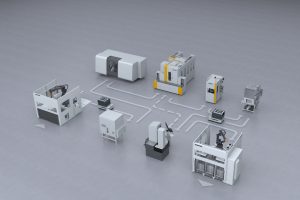

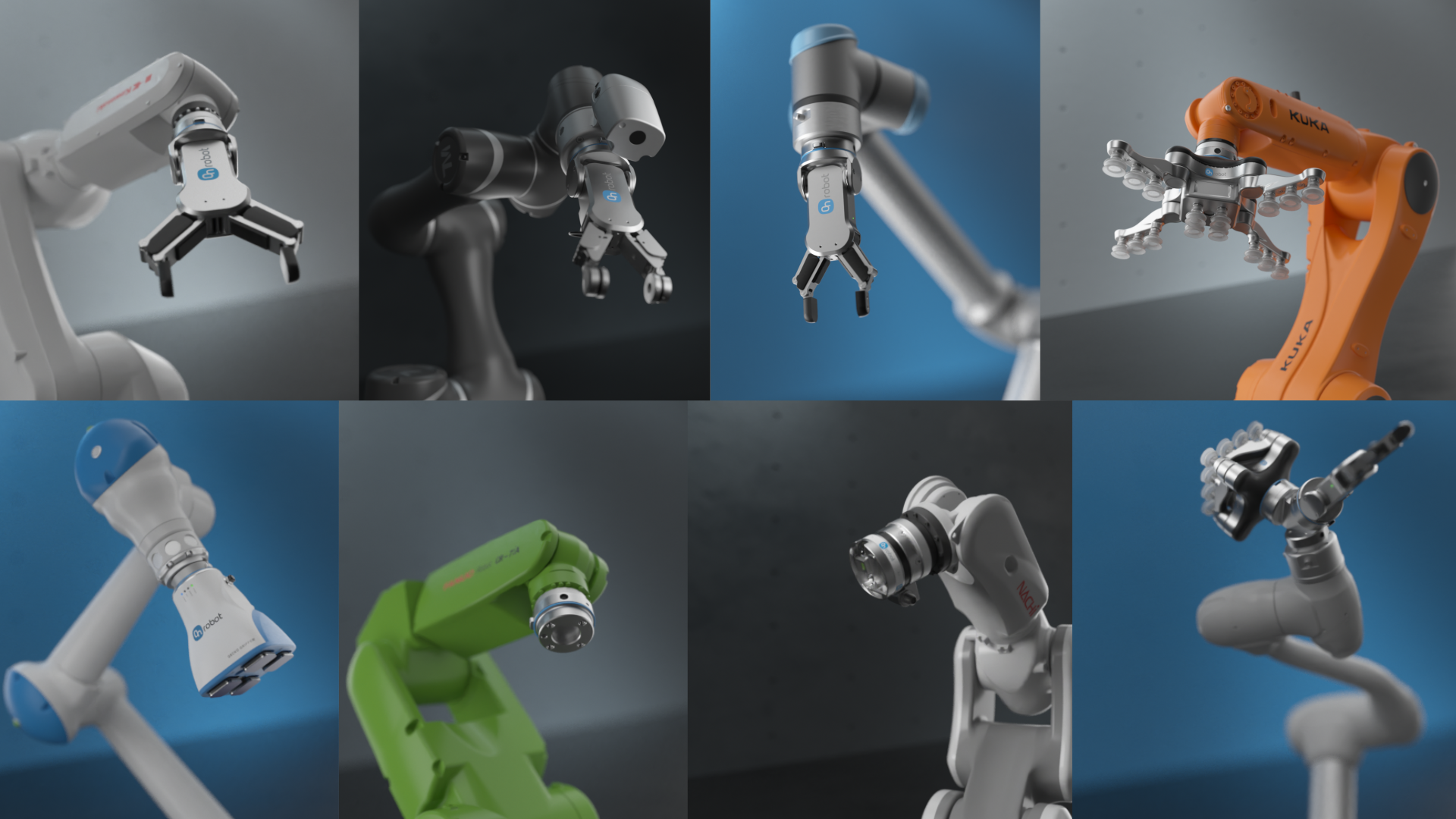

Unified Mechanical and Electrical Interface

OnRobot A/S continues to drive its mission of making robotic applications faster and easier to implement with a unified mechanical and electrical interface for any OnRobot end-of-arm tooling (EoAT) that simplifies automation. Now, with a single robotic system, single platform for programming and training, and single vendor relationship, manufacturers have access to a full range of tools, full robot compatibility, and virtually unlimited possibilities for collaborative applications. This new one-system solution speeds deployment so manufacturers save time and money and can quickly realize the benefits of automation.