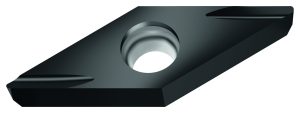

WEP01C Cermet Turning Indexable Inserts

Because of the ground chip breaker on these inserts, the inserts are handed (left hand and right hand insert), but these are standard ISO shapes and sizes- so they are held in conventional ISO turning holders. The inserts also use 'M' or maximum material condition tolerance on the corner radii of the cermet, thus allowing for machining of small radius shoulders while utilizing maximum (larger) corner radius strength. The primary application for the WEP01C cermet inserts is turning steels and cast irons (ISO P and ISO K material groups).