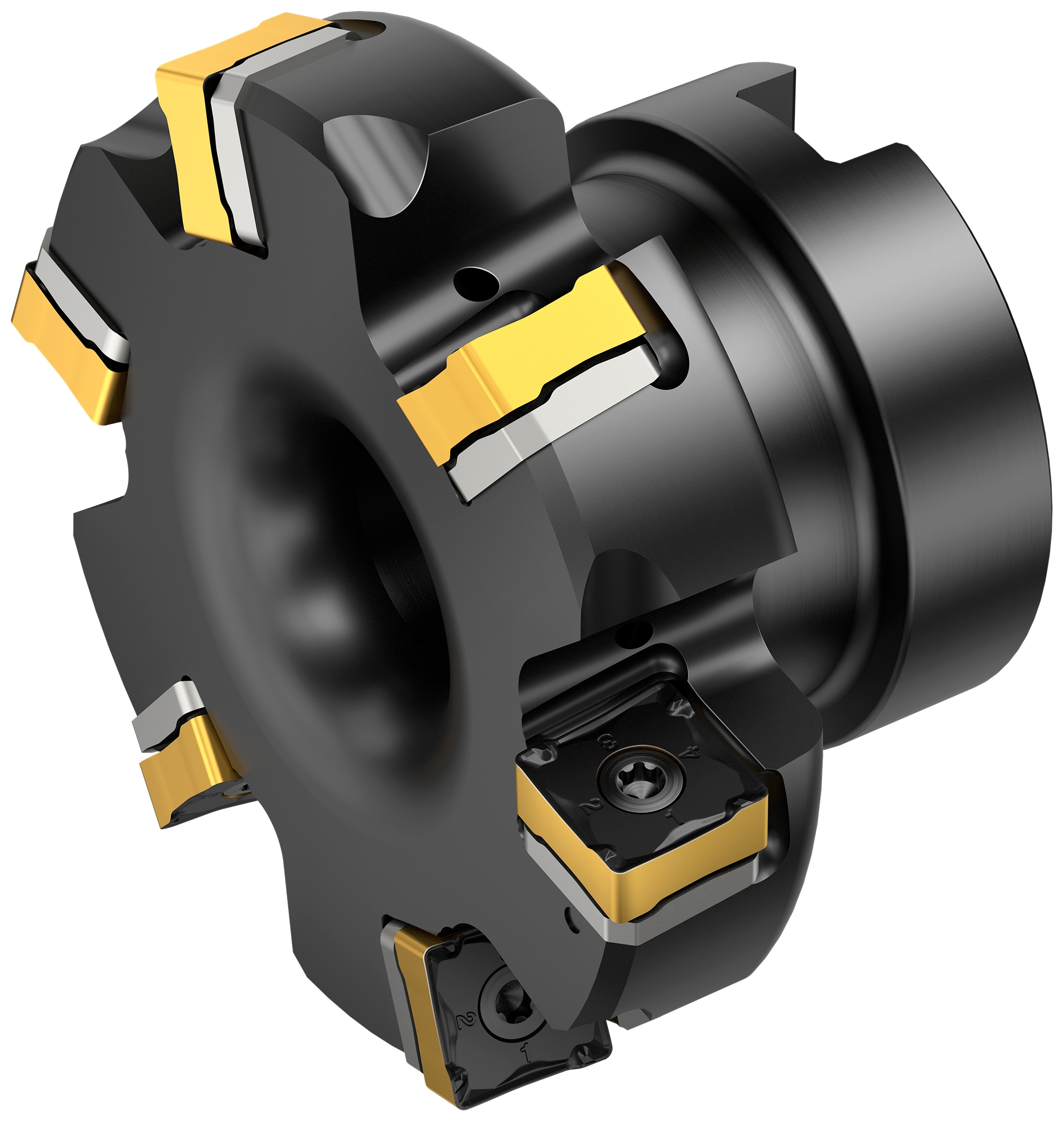

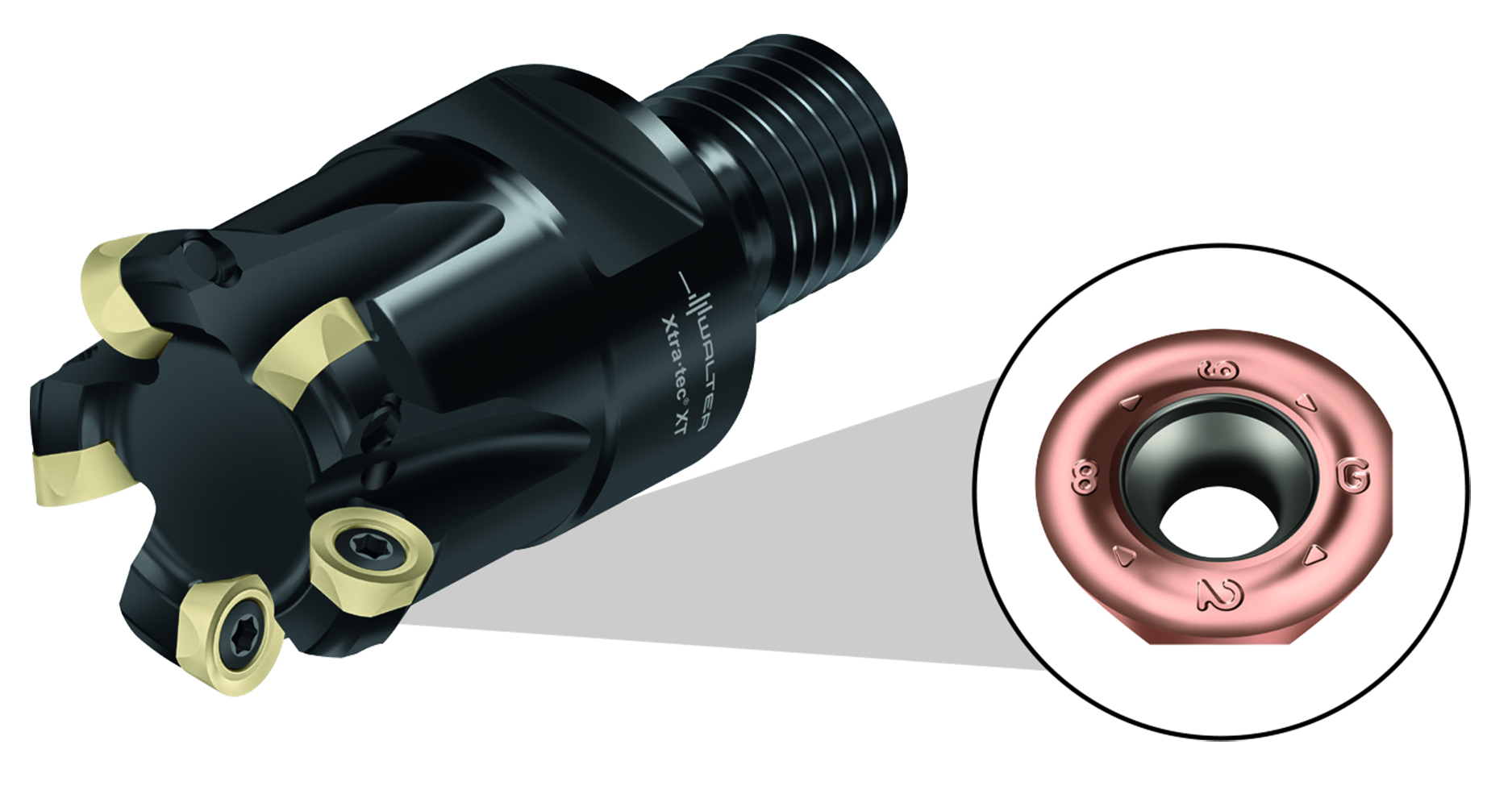

ISO N Grade WXN15

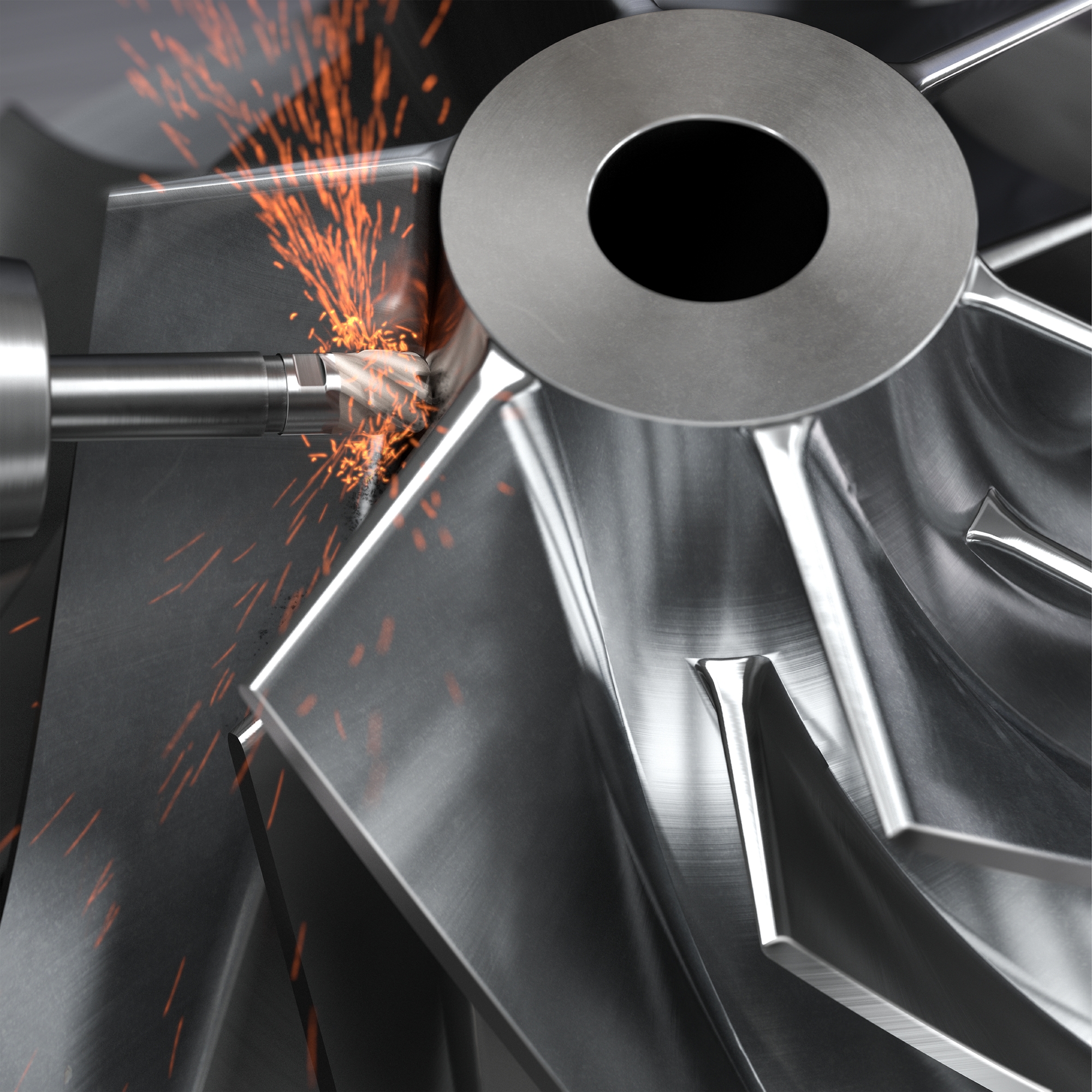

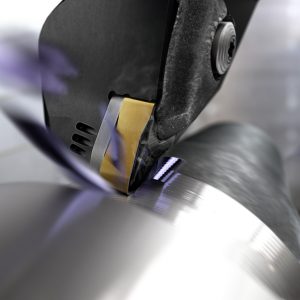

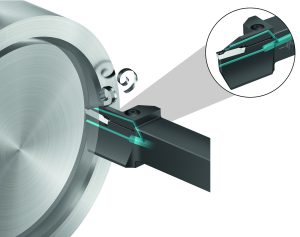

These WXN15 grade coated inserts are all introduced with a highly positive shaped geometry, which is particularly effective in machining ISO N materials. When used in advanced cutter bodies like the new Xtra·tec® XT M5468 button insert milling cutter, with G88 geometry, this also increases productivity when performing machining operations on deep shoulders with excellent chip removal.