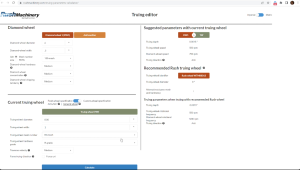

Grinding Doc discusses Truing Parameters Calculator

Jeff Badger, Ph.D., a grinding expert and the author of CTE's Grinding Doc column, provides a practical tour of the Truing Parameters Calculator he helped develop along with Rush Machinery and the International Grinding Institute.n