3B Thread Gages

3B Thread Gages

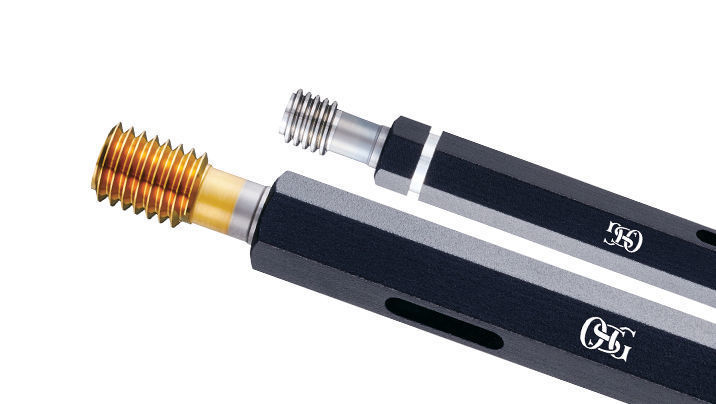

The 3B Thread Gages have the following features: High hardness TiN coating to provide long tool life. Gold coloring to visually analyze the wear condition in seconds.

OSG is pleased to announce the expansion of its 3B Thread Gages! Inch plug thread gages are used to inspect pitch diameter and pitch accuracy of internal threads. OSG inch plug gages are manufactured to Class X tolerances per ANSI B1.2. Go and No-Go gages from OSG are ground from premium HSS and hardened to 64Rc to ensure superior wear resistance. Gages are available with short form certifications.

The following list numbers are associated with the NEW 3B Thread Gages:

- NEW! List #15003 3B Thread Gages

The 3B Thread Gages have the following features:

- High hardness TiN coating to provide long tool life.

- Gold coloring to visually analyze the wear condition in seconds.