3DViewStation 2021

3DViewStation 2021

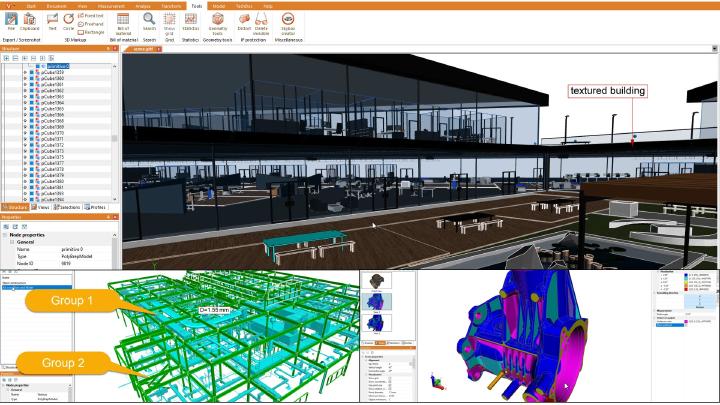

With the newly integrated textures, CAD models appear more detailed and realistic. This look increases the realistic impression of the 3D objects and enhances the design aesthetically. This is particularly interesting for those areas where a realistic representation is important, such as presentations, catalogs or virtual reality. This gives customers a realistic impression of their final product as early as the design phase. The 3DViewStation supports the textures in the file formats OBJ, FBX, GLB / GLTF, DAE, U3D, 3DVS and 3MF.n

Textures, undercut analysis, fast distance calculation among thousands of parts

KISTERS has announced the 2021 release of its 3DViewStation product family, offering a multitude of improvements and enhancements that help users gradually replace costly CAD licenses with an intelligent viewer.

The new features include powerful analysis functions such as undercut calculation in real time and extremely fast distance calculation between thousands of components. In addition, 3DViewStation now also supports textures that bring technical products to life and offers new options for displaying attributes, sections, measurements and selections.

"The new undercut calculation in real time makes it possible to examine complex CAD models for possible manufacturing problems, for example, to estimate the complexity of the required tool," said Jim Eardly, KISTERS North America Sales Manager. "In this way, users can quickly and reliably identify critical areas as early as the offer phase. This leads to a realistic cost calculation and increased competitiveness, since it becomes easier to assess the amount of work required to manufacture a tool."

"Another innovation is the calculation of the minimum distance within an assembly or even the entire scene. In this way, the user can quickly identify the critical areas in which the specified distances are not reached. This is particularly interesting for large and complex models, for example. if entire industrial systems are to be checked," Eardly added. "Typical for such an analysis is the long calculation time in which thousands of component distances have to be calculated. 3DViewStation calculates the minimum distance in a matter of seconds and thus offers quick and reliable protection against costly planning errors."

With the newly integrated textures, CAD models appear more detailed and realistic. This look increases the realistic impression of the 3D objects and enhances the design aesthetically. This is particularly interesting for those areas where a realistic representation is important, such as presentations, catalogs or virtual reality. This gives customers a realistic impression of their final product as early as the design phase. The 3DViewStation supports the textures in the file formats OBJ, FBX, GLB / GLTF, DAE, U3D, 3DVS and 3MF.

Here is an overview of the main improvements:

New and enhanced file formats:

- Import 3D: 3MF, Solidworks 2021

- Import 2D: CATIA V6 / 3DEXPERIENCE R2021x, Solid Edge 2021, SOLIDWORKS 2021, UG NX: NX 1938, NX 1942, NX 1946

- Export 2D: export all views incl. preview images to PDF

New and enhanced functions & features:

- visualization: support for textures

- supported file formats:

- import: OBJ, FBX, GLB/GLTF, DAE, U3D, 3DVS, 3MF

- export: 3DS, 3DVS

- draft angle analysis: new option to show undercuts

- section:

- filled by geometry color

- new method: create section plane perpendicular to selected edge. section plane orientation follows contour of the edge

- measurement: calculate minimum distance between several selections of solids

- measurements using points: snapping of end or center of lines or edges

- PMI: select all PMI attached to the selected geometry

- BOM:

- Extend BOM table by attributes

- generate callout ID by attribute

- assign attributes to markups

- create intersection point of 2 edges

- Offset lines can now remember transformation path

- position camera perpendicular to surface

- show current mouse coordinate in the status bar

- VR only:

- 2 new fly modes

- improved teleport marker

- reposition camera in fix steps

- WebViewer only: share session between several users

Known for its modern user-interface, high performance viewing, advanced analysis and integration capabilities into leading systems, 3DViewStation ships with current and mature importers for a broad range of 3D and 2D formats including i.e. Catia, NX, Creo, SolidWorks, SolidEdge, Inventor, Revit, JT, 3D-PDF, STEP, DWG, DXF, DWF, MS Office and many more.

According to Eardly, KISTERS 3DViewStation is continuously enhanced in response to customer needs and requirements. It is available as Desktop, VR-Edition and HTML5 WebViewer product-versions plus the online collaboration tool VisShare. All product flavors are intended to be used together with a PLM, ERP or other management system product configuration or service and spare part applications, providing all necessary APIs. For cloud, portal and web-solutions, there is an HTML5-based WebViewer solution available, which does not require client installation. All file formats can be used in combination with the intelligent navigation and hyperlinking features to address the needs of complex integration scenarios.