3DxSUITE

3DxSUITE

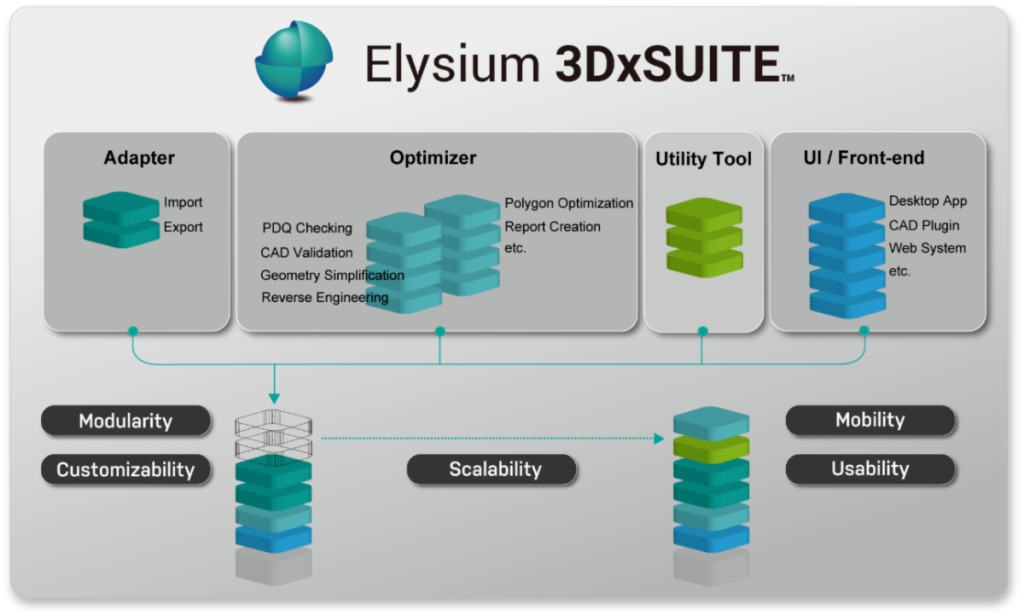

Companies can use the new platform to construct a centralized system that allows them to easily select, combine and integrate modularized functions and usage. This ability will save companies handling 3D engineering data significant time and costs in their model-based and digitalization efforts, and improve supply-chain integration and productivity.n

Global interoperability solutions provider, Elysium, is developing a new consolidated interoperability platform scheduled for release in spring of 2021. The new 3DxSUITE will enable users to customize and integrate Elysium's advanced data solutions into automated quality and compliance-checking systems best suited to their operational needs.

Flexibility and openness support digital end-to-end processes for MBE and the 3D-Master

"For almost 30 years, we have been creating a wide variety of packaged software products based on our unique 3D data-processing technology," says Atsuto Soma, CTO of Elysium. "Now, we are transforming our existing technology into a new platform that can more flexibly meet the demand for greater industry automation and inter-connectivity between CAD data resources and downstream manufacturing processes.

"3DxSUITE truly embodies the 'interoperability' that Elysium has set as its business concept since its foundation," says Soma. "Companies that use 3D to design and manufacture products should not be tied to a specific authoring system or set of tools, but rather transcend the barriers between companies and organizations, creating the ideal manufacturing processes that connect all kinds of information, systems, equipment and people."

Accelerating the digital transformation of manufacturing

In recent years, as digital transformation has progressed across many industries, manufacturing companies have increasingly relied on streamlined 3D data to optimize their supply chains.

"With advanced IT solutions now available, such as cloud applications and web-based portal communications, manufacturers using a variety of CAD software and PLM (Product Lifecycle Management) systems will be able to more broadly and deeply employ Elysium's new platform to fully utilize their 3D digital engineering data," Soma says. "This will facilitate the transformational changes now taking place globally and promote business growth."

Modularity, usability and mobility

Elysium has developed a full spectrum of digital technologies—such as data translation, verification including PDQ (Product Data Quality), validation, optimization including geometry simplification and data repurposing, and even packaging of 3D and supplemental data—and incorporated these into the desktop application CADdoctor; the enterprise solution, ASFALIS; and the foundational data-translation tool, DirectTranslator.

On the upcoming interoperability platform, 3DxSUITE, users will not be limited to any specific configuration of Elysium products, or any particular CAD system or data format. They will be free to pick the manual or automated data solutions that best fit their individual needs with regard to design tools, manufacturing processes, operational systems, etc.

Companies can use the new platform to construct a centralized system that allows them to easily select, combine and integrate modularized functions and usage. This ability will save companies handling 3D engineering data significant time and costs in their model-based and digitalization efforts, and improve supply-chain integration and productivity.

Supporting the evolution of the digital environment

"One of the greatest advantages of this software consolidation is the ease by which customers can start incorporating their first priorities, whether small-scale or large-scale," says Annalise Suzuki, North American VP of Technology & Engagement for Elysium. "When it comes to MBE initiatives, it's not reasonable to seek a radical change overnight. MBD/MBE is a long-term, evolving roadmap as cultures, tools, standards and processes improve. The 3DxSUITE is most accommodating when it comes to supporting such an evolving shift—whether it be adding capabilities over time, expanding use cases, or changing out 3D formats.

"From a value perspective, 3DxSUITE is a single-point solution—a single architecture for upgrading a CAD system and outgoing data across multiple vendors and into set production and delivery schedules. It maximizes throughputs, but minimizes overhead for implementation, integration, configuration, upgrades, and long-term support," says Suzuki