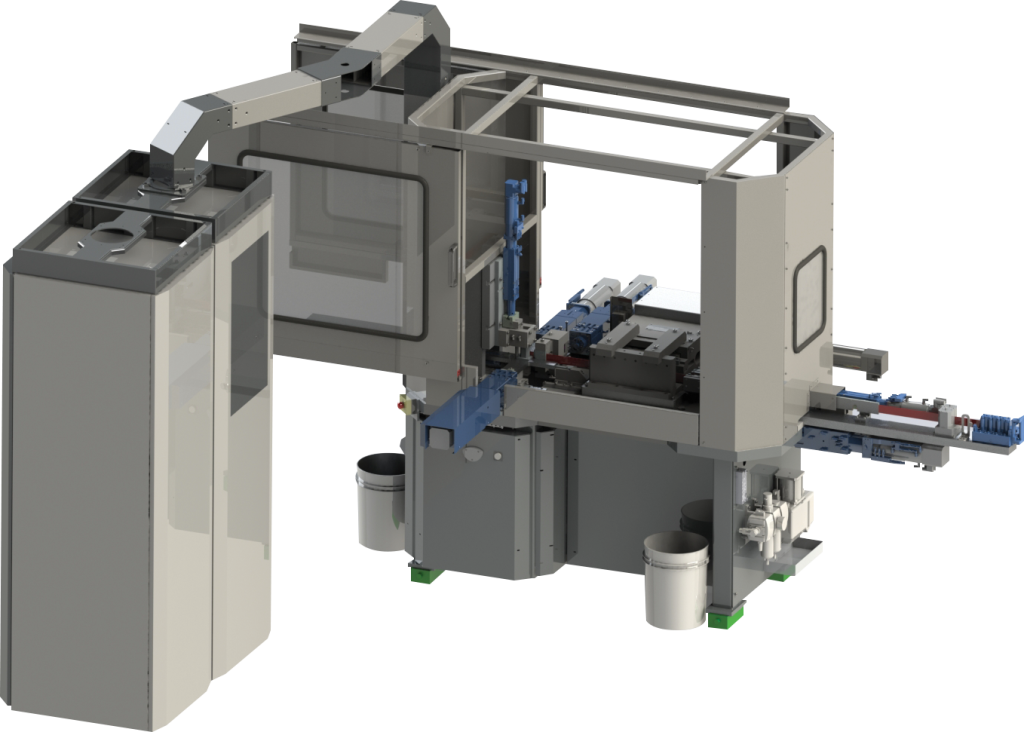

4 Slide-NC Machine

4 Slide-NC Machine

Bihler says a typical client, such as a producer of metal fasteners, is able to phase out six existing machines for each newly installed 4 Slide-NC, while increasing productivity and performance by sixfold. The client could even halt plans for a facility expansion, thanks to a reduction in the overall footprint required, as one new 4 Slide-NC machine outperforms the productivity of six last-generation machines.

Bihler 4 Slide-NC says a typical client, such as a producer of metal fasteners, is able to phase out six existing machines for each newly installed 4 Slide-NC, while increasing productivity and performance by sixfold. The client could even halt plans for a facility expansion, thanks to a reduction in the overall footprint required, as one new 4 Slide-NC machine outperforms the productivity of six last-generation machines. Increases in efficiency, manufacturing uptime, overall productivity, and reduced maintenance costs are directly attributed to the replacement of older four-slide equipment with the Bihler 4 Slide-NC model.

Another popular 4 Slide-NC attribute is its easy-to-use digital control panel, common to the controls used in other Bihler equipment. With an intuitive interface, it allows the operator to completely regulate the production process and automation tasks simply and quickly. "You can program a cam timing change into the control panel in 10 seconds. The value of that alone is well worth the investment for many of our customers, when you consider that a cam timing change on an older machine can take up to eight hours," said Max Linder, director of sales and marketing for Bihler of America.

Bihler 4 Slide-NC, an independent company, is a joint venture of Bihler of America and Otto Bihler Maschinenfabrik, Germany.

Linder indicated a range of attributes that new 4 Slide-NC customers have commented on: "Customers are realizing run rates that are as much as four times faster than previous generation machines." And, the new machines can run millions of parts without needing a single adjustment; they stay in tolerance for the entire duration of the parts run. Customers have also praised the auto-stop feature, as it saves time and minimizes waste.

Further, with many veteran plant operations personnel retiring or nearing retirement in manufacturing operations nationwide, the 4 Slide-NC is easy to learn how to operate. A newly hired machine operator can be trained in less than a day. The easier-to-operate machine also enables senior personnel to dedicate their time and attention to more critical requirements of a manufacturing operation. "You simply don't have to care-take these machines like the olderfour-slide models," Linder pointed out.

Other advantages that Bihler 4 Slide-NC customers have observed include:

- Highly efficient production of strip and wire parts even in small batch sizes

- Rapid response capability for short-term customer requests

- Lot sizes processed in half the time

- Reduced tool costs and debugging time

- Full tool compatibility with select mechanical 4 Slide machines

- Multiple storage for tool setups

- Integrated process and production monitoring