52/96 Workholding Technology for CNC Machining

52/96 Workholding Technology for CNC Machining

The Mate 52/96 workholding system includes QuickSpecs™, Mate's unique product identification system. QuickSpecs allows real-time access to critical user data, CAD models and potential integration into business systems. Additionally, the product supports common robotic interfaces and palletizing systems to support factory automation.

Mate Precision Technologies, a global leader in metal forming and metalworking solutions, announced today that it is launching a new line of 52/96 workholding technology for CNC machining operations. Available in January 2021,

"We are very pleased to introduce a new era of workholding,said Mate Chairman and CEO Dean Sundquist. e were never completely satisfied with the workholding available on the market. Our machinists knew exactly what they wanted so we decided to develop a new, high quality, high performance workholding system."

A New Era for Workholding

Leveraging nearly six decades of machining Mate's workholding line offers an impressive selection of options:

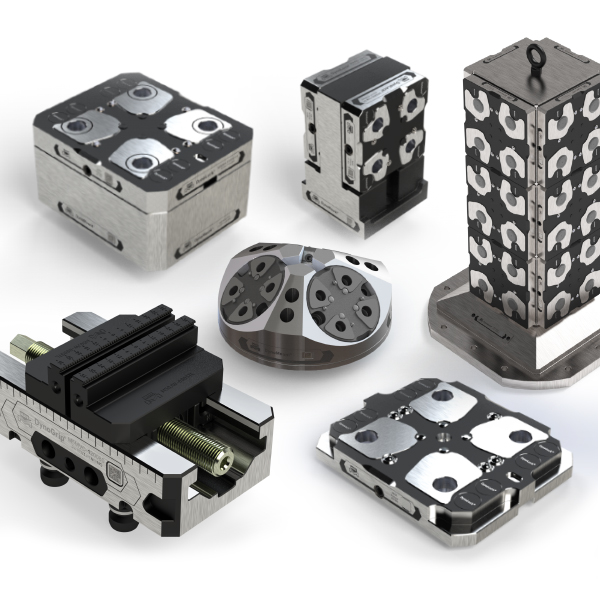

- Mate DynoGrip™ self-centering vises feature maximum holding power in a compact system with minimal part movement and zero-point quality engagement with a four-post pull stud pattern.

- Mate DynoLock™ quick change bases provide zero-point quality engagement with a four-post stud pattern and best-in-class center accuracy and repeatability.

- Mate DynoMount™ system includes tombstones, pyramids, risers, and dual right-angle mounts that feature zero-point quality engagement for four-point stud patterns.

Sundquist explained, "What's really sets this system apart is that our workholding is designed and built by Mate machinists in our Anoka, Minnesota, facility. They know what machinists want in a workholding system because they want those same things themselves."

The Mate 52/96 workholding system includes QuickSpecs™, Mate's unique product identification system. QuickSpecs allows real-time access to critical user data, CAD models and potential integration into business systems. Additionally, the product supports common robotic interfaces and palletizing systems to support factory automation.

This new line is designed and manufactured with Mate's renowned performance standards for best-in-class accuracy and repeatability. The workholding system is backed by the company's sophisticated technical support, unsurpassed product quality, responsive customer service, and 100-percent satisfaction guarantee. Learn more online: mate.com/products/workholding.

The workholding announcement comes shortly after Mate changed its corporate name to Mate Precision Technologies to reflect the company's broader commitment to metalworking and using its expertise to drive innovations to shape the future of factory productivity. In describing the name change Sundquist commented, "It truly supports our mission statement, which focuses on improving our customers' factory productivity, and we are now better positioned to extend our skills and technologies to other markets like the metal cutting and machining industry."