6178C, 6182D and 6183D Miniature Sensors

6178C, 6182D and 6183D Miniature Sensors

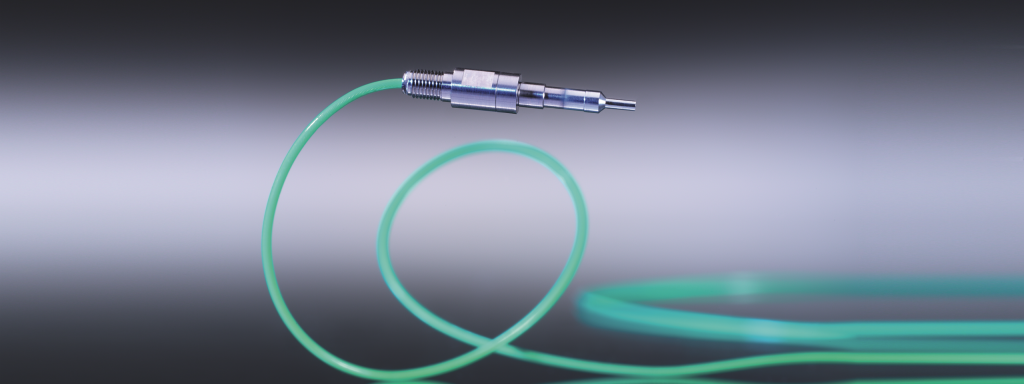

Small and extremely sensitive, but capable of absolute top performance: The advanced miniature sensors (6178C, 6182D and 6183D) from Kistler – streamlined for maximum precision – now feature Unisens uniform sensitivity and titancarbonitite coating.

Small and extremely sensitive, but capable of absolute top performance: The advanced miniature sensors (6178C, 6182D and 6183D) from Kistler – streamlined for maximum precision – now feature Unisens uniform sensitivity and titancarbonitite coating.

These miniature sensors offer a convincing benefit: Unisens uniform sensitivity, ensuring that they achieve accuracy of just a fraction of the previous tolerance range. This added gain in precision eliminates the need for sensor detection in the system. The sensitivity of these sensors remains constantly high, so users no longer have to enter values in the system from each sensor data sheet. This also means that replacing the sensors is very straightforward, so they are far easier to handle – especially when multiple-cavity molds are involved. Tight tolerance ranges and ease of handling will obviously be key advantages for manufacturers of complex high-precision parts such as electrical plugs, and for producers in the automotive and medical technology sectors.

From now on, the new miniature sensors are also available with a titancarbonitite coating (instead of hard chromium). This coating has proven its excellence many times over in the injection molding sector: it provides optimum protection against wear, ensuring longer lifetimes for these high-sensitivity sensors. The titancarbonitite coating offers two decisive advantages: exceptional hardness against abrasion, and resistance to corrosion caused by the action of chemicals. Thanks to these benefits, the new sensors are suitable for use with glass fiber-reinforced plastics and flame-retardant materials.