AGS (Advanced Grinding System) Grinds Fully

AGS (Advanced Grinding System) Grinds Fully

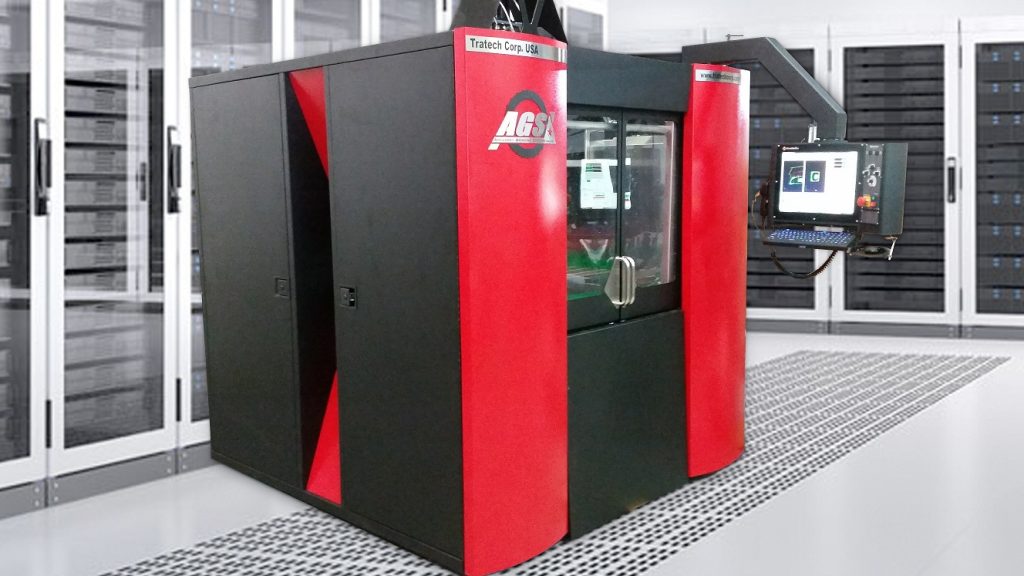

The AGS (Advanced Grinding System) from Tratech Corp. is a specialty-built CNC grinding machine for the demanding needs of machining fully sintered ceramics at a competitive price point. The AGS is a 3-axis CNC machine that includes integrated coolant filtration and temperature control, as well as mist control.

The AGS from Tratech Corp. is a specialty-built CNC grinding machine for the demanding needs of machining fully sintered ceramics at a competitive price point. The AGS is a 3-axis CNC machine that includes integrated coolant filtration and temperature control, as well as mist control.

The system features an ultrahigh-accuracy 42,000-rpm coolant-through spindle, a 500x500x500mm working envelope and a stationary machine bed utilizing an XYZ gantry design that keeps the motion control components safely protected from abrasive ceramic particles. In addition, the bed and motion components are isolated from the machine frame to mitigate environmental impacts on the machining process.

The AGS also features several patent pending technologies like an intelligent process force detection system that will automatically stop the machining process and lift the tool out of the workpiece when overload and tool failure conditions are detected, and a 16-tool toolchanger/" data-glossary-id="142091" data-glossary-teaser="Mechanism typically included in a machining center that, on the appropriate command, removes one cutting tool from the spindle nose and replaces it with another. The changer restor…" title="Mechanism typically included in a machining center that, on the appropriate command, removes one cutting tool from the spindle nose and replaces it with another. The changer restor…" aria-label="Glossary: toolchanger/" data-glossary-id="142091" data-glossary-teaser="Mechanism typically included in a machining center that, on the appropriate command, removes one cutting tool from the spindle nose and replaces it with another. The changer restor…" title="Mechanism typically included in a machining center that, on the appropriate command, removes one cutting tool from the spindle nose and replaces it with another. The changer restor…" aria-label="Glossary: automatic toolchanger">automatic toolchanger">automatic toolchanger that features an on the fly (OTF) tool tray system that keeps a massive 256 tools in process storage. Tools and trays can easily be swapped and loaded without interrupting the machining process.

The AGS has successfully demonstrated performance gains in various materials like high-purity quartz glass, sapphire, boron carbide, alumina oxide and zirconia nitride, and in various applications like heavy stock removal and producing precision 3D shapes and delicate, thin wall features. The president of Tratech Corp., Christian Travert, stated, "If our system can't deliver at least a two times performance gain for your company, we'll return the machine at no cost."