Ball-Grip Chucks

Ball-Grip Chucks

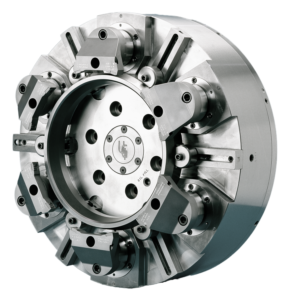

Ball-Grip chucks are used for first operation roughing and/or second operation finishing. The basic chuck is modified to suit machine mounting, the need for coolant and/or air through, and mounting for top tooling, which is designed to a customer's part and machining requirements.

Ball-Grip chucks are used for first operation roughing and/or second operation finishing. The basic chuck is modified to suit machine mounting, the need for coolant and/or air through, and mounting for top tooling, which is designed to a customer's part and machining requirements. Ball-Grip chucks are available in standard sizes up to 33″ (838.2mm) and special sizes up to 79″ (2m). Larger sizes available upon request.

Basic Standard Style Options:

- Two-, Three-, Four- and Six-Jaw Chucks

- Internal and External Chucking

- Centralizing, Compensating, Centralizing-Compensating, and Equalizing/Centralizing chucking mode.

Standard Features:

- Pull Down or Pull-Back Action – Assist in providing positive location against work stop.

- Jaw Swivel (Homing) – Jaw compensates for part variation insuring 2 point contact with each jaw.

- Jaw Travel – Increased jaw travel enhances part loading and tolerance variations.

- Sealed Design – Sealed slides significantly reduce costly maintenance and resulting down time.

- Ball Joint Construction – Power mechanism operates within a sealed unit of high pressure lubricant.

- High Power Ratio – Higher gripping force with less input resulting in longer chuck life.

- Differential Chucking – Chuck allows for High-Low pressure chucking.

Optional Features:

- Coolant- and/or Air-through center bore.

- Quick-change External/Internal chucking available for two and three jaw chucks.

- Quick change Jaw Mounting for rapidly changing work piece tooling.

- "W" series Platform style Jaw Mounting available to mount customers existing tooling.

- Counter Centrifugal option counteracts the negative effect of centrifugal force to accommodate high-speed applications.