Base Mount Tooling

Base Mount Tooling

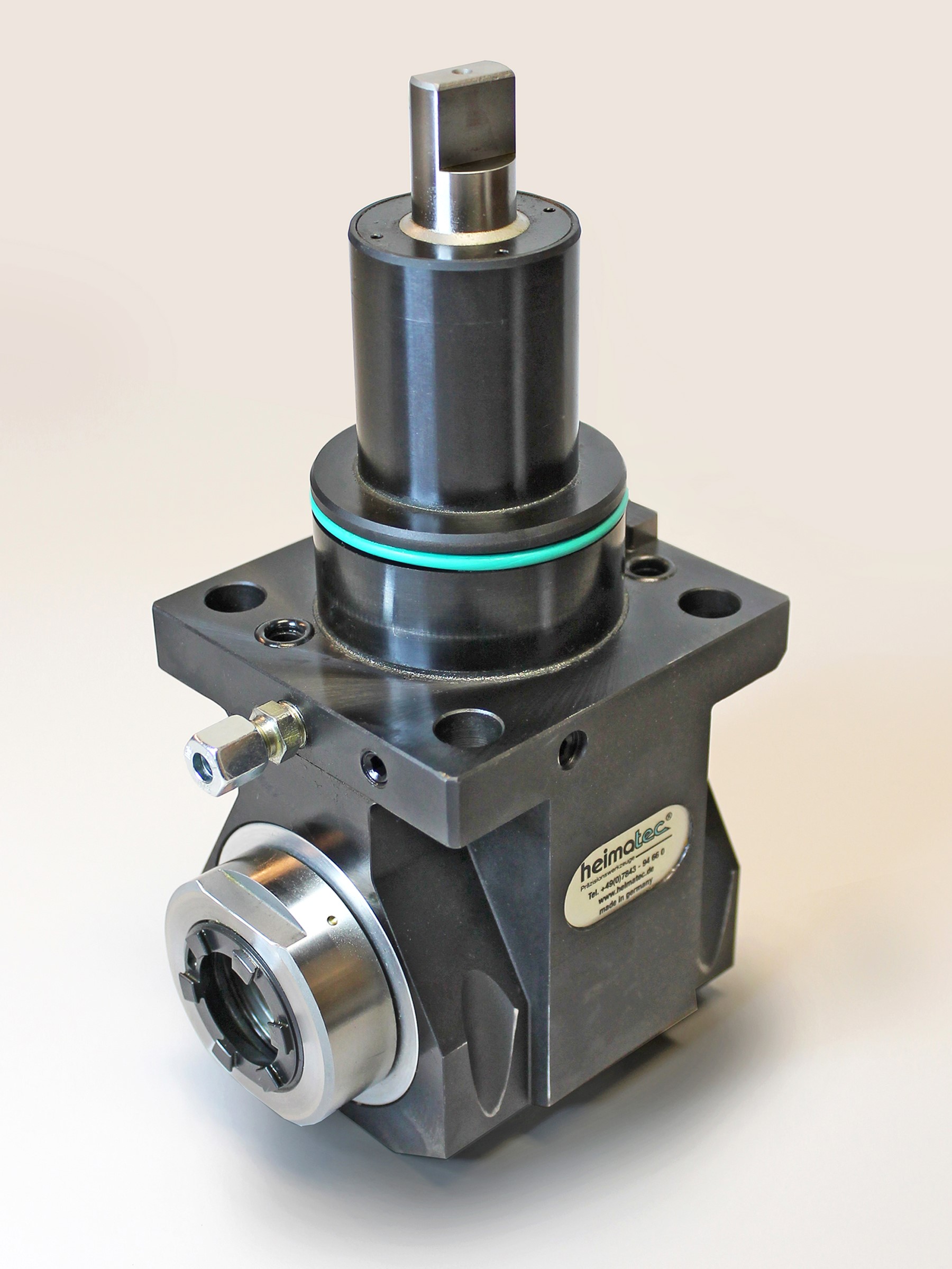

Heimatec announces immediate availability of BMT (Base Mount Tooling) standard products. In addition to standard X- and Z-axis tools, styles such as adjustable tools, speed increasers and internal coolant tools with capabilities to 140 bar (2,000 psi) are available in an assortment of standard BMT tooling types, including BMT 45, 55, 65 and 75.

Heimatec announces immediate availability of BMT (Base Mount Tooling) standard products. In addition to standard X- and Z-axis tools, styles such as adjustable tools, speed increasers and internal coolant tools with capabilities to 140 bar (2,000 psi) are available in an assortment of standard BMT tooling types, including BMT 45, 55, 65 and 75.

All Heimatec BMT tooling is supplied with the company's U-Tec flexible machining system, which provides high power transmission via polygonal drive. Integrated collet nut, with easy changeout, can convert the output to arbor (for facemills), Weldon or ER collet extensions. The U-Tec system further allows the cutting tool to be in closer proximity to the bearing, which results in much higher rigidity. The cutting tools last longer and yield an improved finish, as a result of this Heimatec design feature.