Big Bore

Big Bore

Ideal for handling the harsh demands of the Oil and Gas industry, Big Bore and all of its variations is ideal for machining straight pipe, bent pipe and threading of couplings in two setups. This revolutionary chuck also offers extended jaw stroke for greater clearance to ensure safety for the and loading and unloading of the many variations found in oil field pipe.

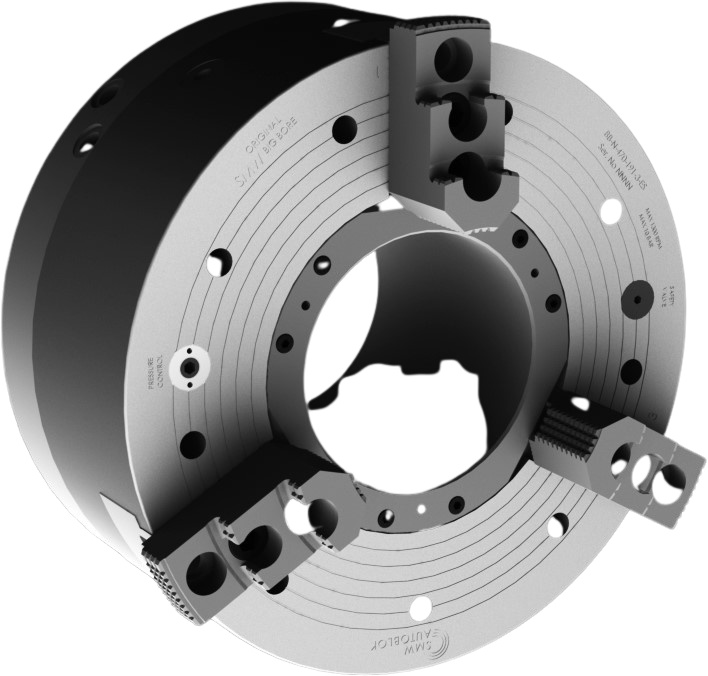

SMW Autoblok, a world leader in the design and manufacture of rotational chucks, stationary workholding, tooling,and custom engineered solutions for the machine tool industry,presents the BIG BORE® (BB-N-ES) pneumatic air chuck featuring both rapid and clamping stroke for short clamping cyclesand use of full spindle bore for large pipe.

BIG BORE is the first chuck developed for end machining of long pipe and full utilization of the spindles through hole. These aremade possible by two principles invented by SMW Autoblok including air supply through a distributor ring and SMW-profile seal rings. Built-in non-return valves maintain air pressure during machining and the clamping pressure is constantly check by a safety control system.

Ideal for handling the harsh demands of the Oil and Gas industry, Big Bore and all of its variations is ideal for machining straight pipe, bent pipe and threading of couplings in two setups. This revolutionary chuck also offers extended jaw stroke for greater clearance to ensure safety for the and loading and unloading of the many variations found in oil field pipe.

BIG BORE is available in 400 mm to 1000 mm and features large through holes of 140 to 560 mm.