Contact Details

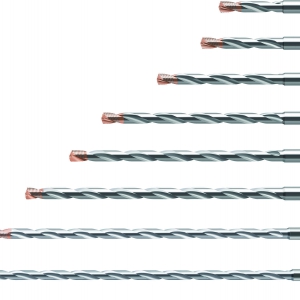

Walter USA LLC has expanded its line of Walter Blaxx milling cutters with the introduction of the F5138, the first helical flute cutter in the Blaxx family. Bearing the distinctive glossy black surface of the Blaxx family that protects it from corrosion and wear, this new model achieves profiling and shoulder milling feed rates far in excess of those achieved by conventional cutters. Blaxx is ideal for work in steel, stainless steel, non-ferrous metal, difficult to cut material, or cast iron.

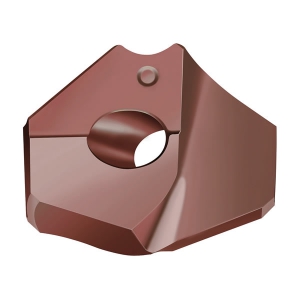

The new F5138 helical flute cutter includes four-edged, tangential indexable inserts made from Walter Tiger-tec Silver high-performance cutting material and manufactured using the latest carbide technology. The inserts are positioned in the cutter to ensure there is a large mass of carbide in the direction of the cutting forces.

Thanks to the design of the insert seat, the tool body has a reinforced core, benefitting from an extremely large material cross-section. The resulting robustness enhances the stability of the cutters. Additionally, the inserts' helically positioned cutting edges with free-cutting geometries and excellent concentricity reduce cutting forces and vibration, enhancing stability, surface finish and quality.

With four available grades, ranging from very hard to very tough, users can select the optimum grade for their workpiece: Grades WKP25S and WKP35S for steel and cast iron, or WSM35S and WSP45S for stainless steel and difficult to cut materials.

The F5138 diameters range of 1 ½ to 3 inches (40 to 80mm) with two different cutting lengths per diameter. Optional internal coolant supply to all cutting edges is also available. The tool is equipped with the same indexable insert system as the F5141 shoulder mill. Consequently, users can use one insert size for both tools.

Related Glossary Terms

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- indexable insert

indexable insert

Replaceable tool that clamps into a tool body, drill, mill or other cutter body designed to accommodate inserts. Most inserts are made of cemented carbide. Often they are coated with a hard material. Other insert materials are ceramic, cermet, polycrystalline cubic boron nitride and polycrystalline diamond. The insert is used until dull, then indexed, or turned, to expose a fresh cutting edge. When the entire insert is dull, it is usually discarded. Some inserts can be resharpened.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- profiling

profiling

Machining vertical edges of workpieces having irregular contours; normally performed with an endmill in a vertical spindle on a milling machine or with a profiler, following a pattern. See mill, milling machine.

PRODUCTS

PRODUCTS